Biocompatible electrode component and method for fabrication thereof

A technology of biocompatibility, construction method, applied in the field of electrodes and their manufacturing, which can solve problems such as insufficient conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

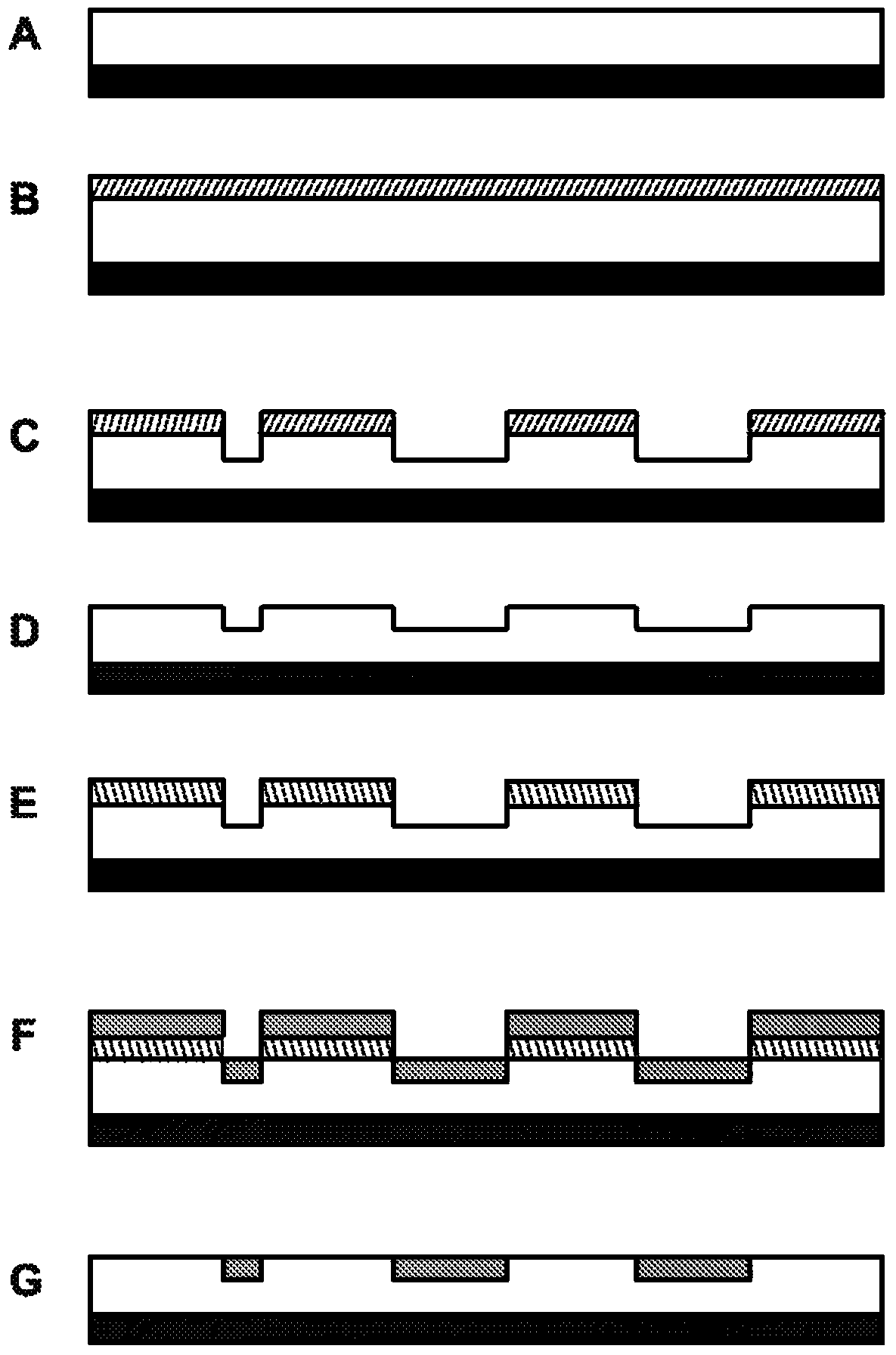

[0131] Example 1: Fabrication of Electrode Parts Using Silicone as a Support and Platinum as Conductive Material

[0132] Silicone elastomer MED4860 was mixed and diluted in 40% by weight heptane ( figure 1 a).

[0133] A piece of substrate was placed on the chuck of the spin coater and the surface of the substrate was covered with silicone using a pipette.

[0134] Adjust the spin coating rate and duration to the viscosity of the silicone to obtain the desired thickness of about 15-20 microns. For MED4860 silicone diluted with 40% heptane, the following conditions were used: 2000 rpm for 20 seconds to obtain a 15 micron thick layer. Immediately after spin coating, the sample was placed on an electric furnace set at 100° C. and left to evaporate the solvent for 20 minutes, which was sufficient to obtain a cured silicone film. Spin coating can be repeated several times to build thicker films when needed.

[0135] When the desired film thickness is reached, the silicone fi...

example 2

[0145] Example 2: First Alternative Fabrication of Electrode Components Using Silicone as Support and Platinum as Conductive Material Substitution Method ("Design A")

[0146] The electrode components in this example were prepared in a manner similar to that disclosed in Example 1, except that the silicone support was solvent cast from a silicone solution. The mold was made of Teflon into which the silicone solution was poured. Solutions were prepared at lower viscosities than those typically used for spin coating.

[0147] After casting, any solvent is evaporated and the silicone is allowed to cure. Curing was accelerated by heating to 90° C., under which conditions curing was achieved in 30 minutes. After solidification and cooling, the sheets are peeled from the mold.

[0148] More variance in the electrode parts produced in this example is the use of a silicone protective layer instead of Kapton TM tape, and a silicone mask was used instead of the brass foil disclo...

example 3

[0154] Example 3: Second Alternative Fabrication of Electrode Components Using Silicone as a Support and Platinum as Conductive Material Alternative approach ("Design B").

[0155]In addition to the methods described in Examples 1 and 2, silicone substrates can be modified by laser machining of silicone to produce higher surface areas. In this example, the fused silica content in the silicone was increased. Alternatively, any other organic or inorganic (non-metallic) nanoparticles or microparticles can be used as fillers. The formulation and fraction of the filler is adjusted such that the silicone retains the desired elasticity. The particles are evenly distributed within the matrix, and these particles are not ablated by the laser when laser processing silicone. Thus, vaults are formed in the silicone carrier. Since the particles are not tightly embedded within the silicone matrix, they are washed away so that only the silicone remains on the surface. These domes inc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com