Tobacco stem soaking water recycling method

A technology for soaking stems and tobacco, which is applied in the fields of tobacco, tobacco preparation, and tobacco treatment. It can solve the problems of high sewage treatment costs, waste of fresh water resources, waste of tobacco flavor resources, etc., achieve obvious application value and economic and social benefits, and save sewage Dealing with costs, improving the effect of smoking quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

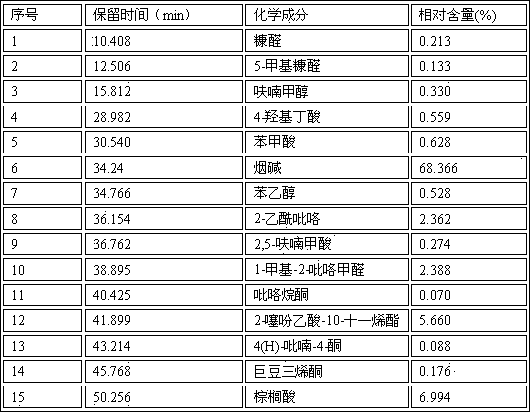

[0014] In order to test the actual improvement effect of the present invention, the inventors first analyzed and detected the chemical components of the aroma substances in the soaking water, which is the waste water produced after the flue-cured tobacco stems in production are soaked in hot water at 60°C for 50s. , the detection procedure and brief process are as follows: Weigh 20mL of steeping water into a 100mL separatory funnel, add 15mL×3 dichloromethane for extraction, combine the organic phase, add anhydrous sodium sulfate to dry, filter, concentrate to 1mL, and carry out GC / MS analysis.

[0015] The analysis conditions are: GC conditions, chromatographic column, DP-5MS (50 m×0.32 mm×0.25 μm) capillary column; inlet temperature, 250 ℃; carrier gas, helium, flow rate 1 ml / min (constant flow mode) ; Injection volume, 1 μl, temperature program, 50 ℃ (1 min), 4 ℃ / min, 160 ℃ (5 min), 4 ℃ / min, 260 ℃ (10 min); split ratio 10:1. Solvent delay 5 min; interface temperature, 280 ...

Embodiment 2

[0020] Based on the analysis of the chemical composition of the steeping water, taking the steeping water with the same chemical composition of the aroma substance as in Example 1 as an example, the inventor conducted a further experimental test on the recycling method of the tobacco steeping water.

[0021] The specific process is as follows:

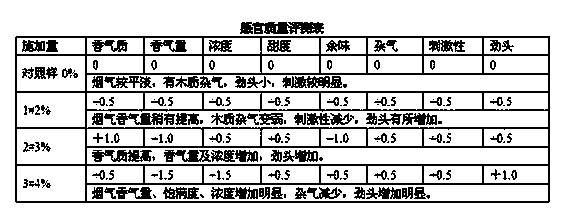

[0022] Soak flue-cured tobacco stems in hot water at 60°C for 50s, let stand to cool, filter, and apply them to the flue-cured tobacco in the feeding process at the ratio of 2wt%, 3wt%, and 4wt%, respectively, in place of the existing water In the type tobacco leaves, it is added in the feeding process, and the tobacco leaves are the lower tobacco leaves (because the lower tobacco leaves have less aroma and contain less aroma substances, so the effect is more obvious), three groups of samples were made, and the unadded tobacco leaves were used as As for the control sample, the shreds were dried and rolled into cigarettes respectively. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com