Preparation method of high-performance palladium/graphene methanoic acid oxidation catalyst

A formic acid oxidation and graphene technology, which is applied in the field of formic acid oxidation catalyst preparation, can solve the problems of unsatisfactory catalytic performance of formic acid, large palladium metal crystal particle size, and small specific surface of carbon carrier, and achieve excellent long-term stability, high ratio Surface area, the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation method of the palladium / graphene high-performance formic acid oxidation catalyst of the present embodiment may further comprise the steps:

[0029] 1) Dissolve 10.5mg of graphene, 50mg of polyvinylpyrrolidone and 12mg of ammonium chloropalladate in 2ml of water to prepare a mixed solution;

[0030] 2) After ultrasonically dispersing the mixed solution prepared in step 1) for 30 minutes, add 3ml of formic acid, and continue to ultrasonically mix for 5 minutes;

[0031] 3) Put the solution homogeneously mixed in step 2) in a reaction kettle for hydrothermal reaction at 120°C for 12 hours;

[0032] 4) Wash the product of the hydrothermal reaction in step 3) and dry it at 60°C for 6 hours to obtain a palladium / graphene high-performance formic acid oxidation catalyst.

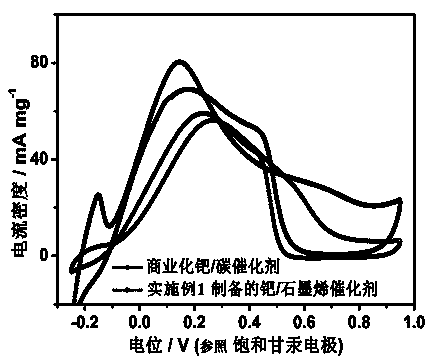

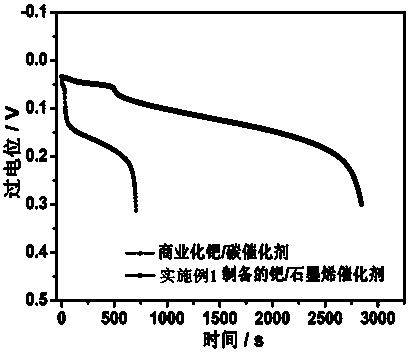

[0033] figure 1 The transmission electron microscope figure of the palladium / graphene catalyst prepared for embodiment 1; can clearly find out from the figure that ultra-small palladium meta...

Embodiment 2

[0038] The preparation method of the palladium / graphene high-performance formic acid oxidation catalyst of the present embodiment may further comprise the steps:

[0039] 1) Dissolve 18mg of graphene, 70mg of polyvinylpyrrolidone and 12mg of ammonium chloropalladate in 3ml of water to prepare a mixed solution;

[0040] 2) After ultrasonically dispersing the mixed solution prepared in step 1) for 40 minutes, add 4ml of formic acid, and continue to ultrasonically mix for 10 minutes;

[0041] 3) Put the solution homogeneously mixed in step 2) in a reaction kettle for hydrothermal reaction at 140°C for 8 hours;

[0042] 4) Wash the product of the hydrothermal reaction in step 3) and dry it at 80°C for 6 hours, which is a palladium / graphene high-performance formic acid oxidation catalyst.

[0043] Figure 4 For the transmission electron microscope figure of the palladium / graphene catalyst prepared in embodiment 2; from the figure, it can be clearly seen that ultra-small palladium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com