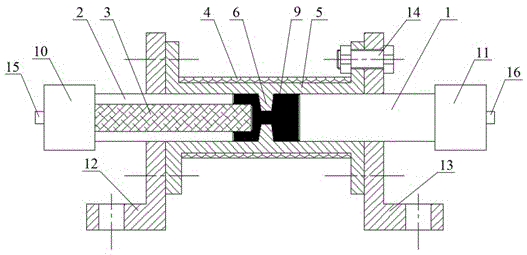

Reciprocating extrusion device and processing method for preparing ultrafine grain magnesium alloy

A technology of ultra-fine grain and reciprocating extrusion, which is applied in the field of machinery, can solve the problems of grain growth, affect the effect of grain refinement, and affect production efficiency, and achieve the effects of high production efficiency, increased strength, and convenient heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

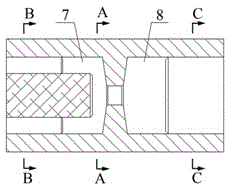

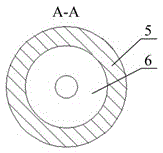

[0053] The magnesium alloy bar with a length of 40 mm is processed into a circular tube blank 9 with a diameter 0.1 mm smaller than the inner diameter of the extrusion barrel die 5 and 0.1 mm larger than the diameter of the fixed extrusion rod 3 , and the surface oil is cleaned. Put the magnesium alloy tube blank 9 into a heating furnace at 350° C. and keep it warm for 1 hour. Turn on the heating jacket 4, heat the extrusion die, and keep it warm for 30 minutes when it reaches 350°C. Place the magnesium alloy pipe blank 9 in the left cavity 7 of the extrusion cylinder mold 5, and extend the extrusion ring 2, the fixed extrusion rod 3 and the extrusion rod 1 into the left and right cavity 7 of the extrusion cylinder mold 5 , 8, and contact the magnesium alloy tube blank 9. Open the hydraulic extrusion machine, the extrusion pressure of the extrusion ring 2 is 900MPa, the extrusion pressure of the extrusion rod 1 is 200MPa, and the extrusion ring 2 pushes the magnesium alloy pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com