Method and device for extracting boron from saline brine by using air-floatation polymers

A salt lake brine and polymer technology, applied in the direction of boron/boride, etc., can solve the problem of not wide pH range, and achieve the effect of fast extraction speed and wide range of solution pH adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

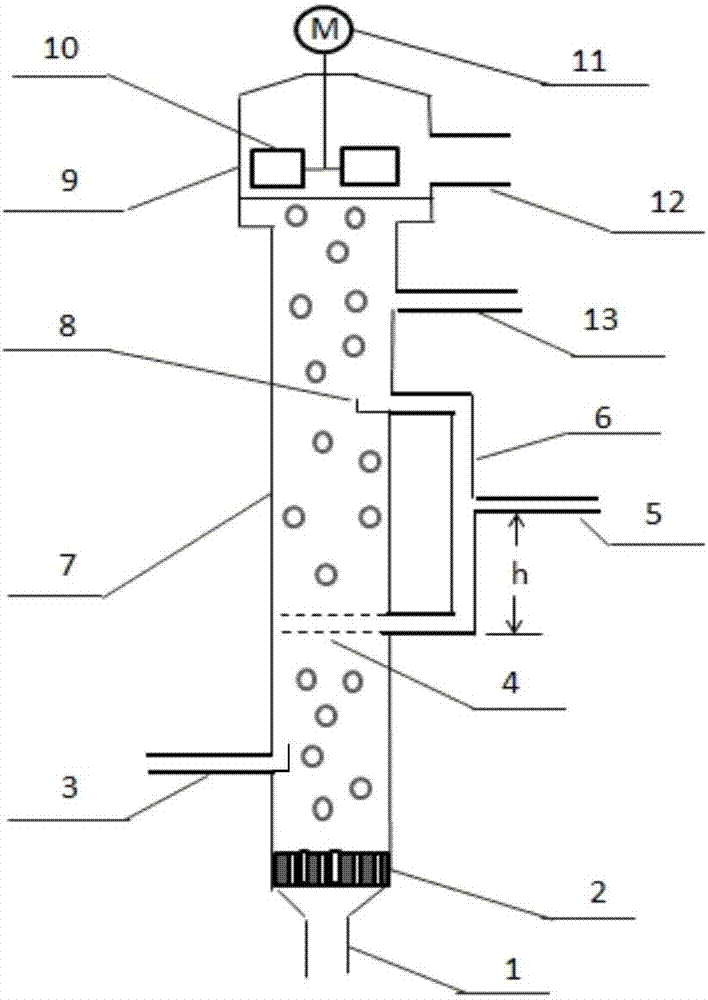

[0048] Take B 2 o 3 300ml of salt lake brine with a mass fraction of 0.1% is filled to such figure 1 shown in the air flotation extraction column. Air is blown in from the gas inlet 1 shown in the figure, and the blowing rate is 0.1mL / min. From figure 1 The indicated water-soluble polymer aqueous solution inlet 5 was added 1.5 mL of a polymer polyethylene glycol PEG (molecular weight: 2000) aqueous solution at a rate of 0.01 mL / min at a rate of 0.01 mL / min. The bubble foam at the top of the air flotation extraction column is collected by the foam scraper 10, the boron in the foam is back-extracted with hydrochloric acid, and the boron concentration in the salt lake brine water sample flowing out from the salt lake brine outlet 3 is analyzed, and the boron air flotation extraction rate is calculated to be 85%. .

specific Embodiment 2

[0049] Take B 2 o 3 300ml of salt lake brine with a mass fraction of 3% is filled to such figure 1 shown in the air flotation extraction column. Nitrogen is blown in from the gas inlet 1 shown in the figure, and the blowing rate is 100mL / min. From figure 1 The water-soluble polymer aqueous solution inlet 5 shown in the figure adds 240 mL of an aqueous solution of polymer ethylene oxide-propylene oxide copolymer (EOPO) (molecular weight: 2500) with a polymer mass fraction of 80% at a rate of 0.01 mL / min. The bubble foam at the top of the air flotation extraction column is collected by the foam scraper 10, the boron in the foam is back-extracted with hydrochloric acid, and the boron concentration in the salt lake brine water sample flowing out of the salt lake brine outlet 3 is analyzed, and the boron air flotation extraction rate is calculated to be 82%. .

specific Embodiment 3

[0050] Take B 2 o 3 300ml of salt lake brine with a mass fraction of 0.01% is filled to such figure 1 shown in the air flotation extraction column. Air is blown in from the gas inlet 1 shown in the figure, and the blowing rate is 20mL / min. From figure 1The water-soluble polymer aqueous solution inlet 5 shown in the figure adds 30 mL of a high molecular polymer polyoxyethylene-polyoxypropylene-polyoxyethylene triblock copolymer aqueous solution with a mass fraction of high molecular polymer of 8% at a rate of 2 mL / min. The bubble foam at the top of the air flotation extraction column is collected by the foam scraper 10, the boron in the foam is back-extracted with hydrochloric acid, and the boron concentration in the salt lake brine water sample flowing out of the salt lake brine outlet 3 is analyzed, and the boron air flotation extraction rate is calculated to be 80%. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com