Anti-corrosion wear-resisting and ageing-resistant modified polyvinyl chloride (PVC) plastic composition

A plastic composition and anti-aging technology, applied in the field of plastics, can solve the problems of high cost, inability to meet corrosion resistance, wear resistance and anti-aging, poor comprehensive performance of heat-resistant PVC materials, etc., and achieve the effect of high pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

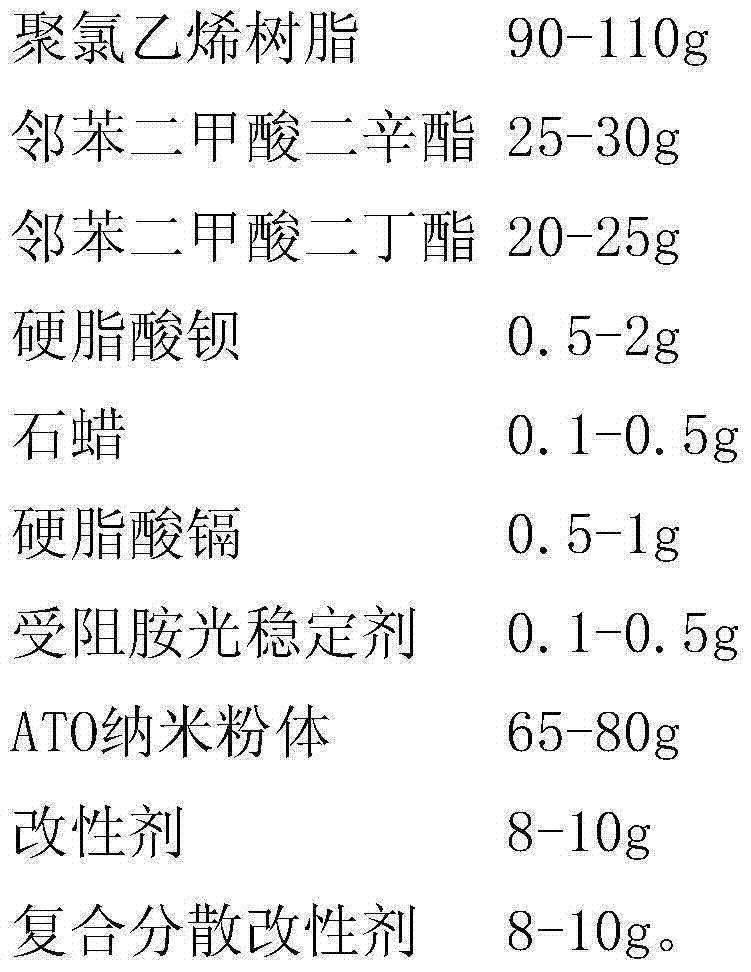

[0020] A corrosion-resistant, wear-resistant and anti-aging modified PVC plastic composition, consisting of the following components in weight percentages,

[0021]

[0022] The ATO nanopowder has a particle size of 3-50nm and a bulk density of 0.4-1.5g / cm 3 , the antimony doped mole percentage is 3-25%;

[0023] The composite dispersion modifier is a nano-powder composite dispersion modifier, or is composed of oleic acid and PVP at a mass ratio of 0.5-3.

[0024] 1) Weigh various raw materials according to the weight percentage of the components;

[0025] 2) Mix polyvinyl chloride resin and paraffin for 3-5 minutes, add hindered amine light stabilizer and heat up to 90-100°C and mix for 5-10 minutes;

[0026] 3) Add the remaining components, heat up to 120-130°C and mix for 5-10 minutes to make the components evenly dispersed, cool down to 40-50°C and discharge, and cool at room temperature for 4-6 hours;

[0027] 4) Put the cooled material into the twin-screw extruder,...

Embodiment 2

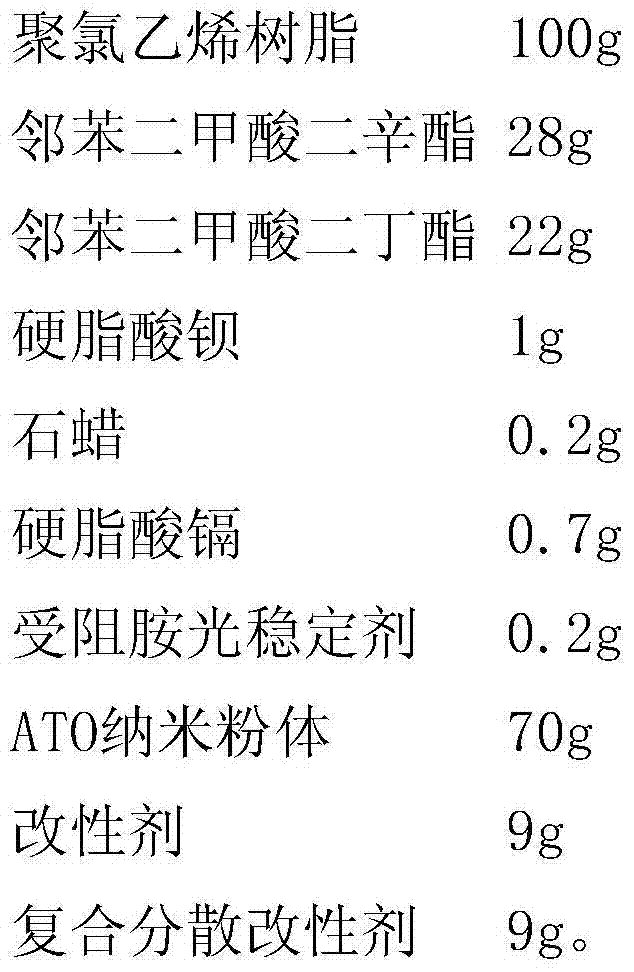

[0029] A corrosion-resistant, wear-resistant and anti-aging modified PVC plastic composition, consisting of the following components in weight percentages,

[0030]

[0031] 1) Weigh various raw materials according to the weight percentage of the components;

[0032] 2) Mix polyvinyl chloride resin and paraffin for 3-5 minutes, add hindered amine light stabilizer and heat up to 90-100°C and mix for 5-10 minutes;

[0033] 3) Add the remaining components, heat up to 120-130°C and mix for 5-10 minutes to make the components evenly dispersed, cool down to 40-50°C and discharge, and cool at room temperature for 4-6 hours;

[0034] 4) Put the cooled material into the twin-screw extruder, extrude and granulate.

Embodiment 3

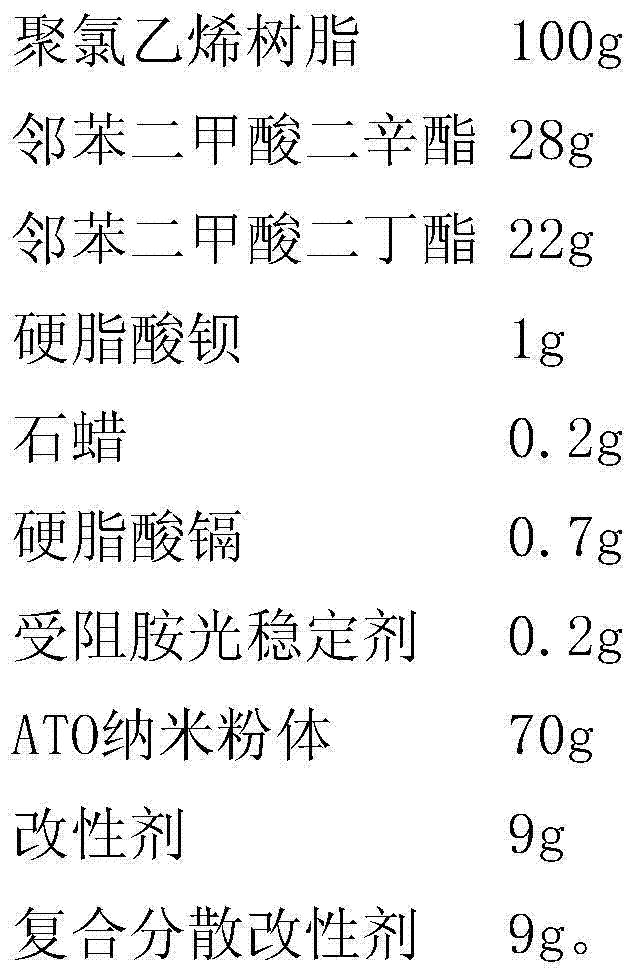

[0036] A corrosion-resistant, wear-resistant and anti-aging modified PVC plastic composition, consisting of the following components in weight percentages,

[0037]

[0038]

[0039] The ATO nanopowder has a particle size of 3-50nm and a bulk density of 0.4-1.5g / cm 3 , the antimony doped mole percentage is 3-25%;

[0040] The composite dispersion modifier is a nano-powder composite dispersion modifier, or is composed of oleic acid and PVP at a mass ratio of 0.5-3.

[0041] 1) Weigh various raw materials according to the weight percentage of the components;

[0042] 2) Mix polyvinyl chloride resin and paraffin for 3-5 minutes, add hindered amine light stabilizer and heat up to 90-100°C and mix for 5-10 minutes;

[0043] 3) Add the remaining components, heat up to 120-130°C and mix for 5-10 minutes to make the components evenly dispersed, cool down to 40-50°C and discharge, and cool at room temperature for 4-6 hours;

[0044] 4) Put the cooled material into the twin-scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com