Compression resistance static loading test system for foundation

A test system, anti-compressive static load technology, applied in the test of basic structure, basic structure engineering, construction, etc., can solve problems such as inability to work, increase failure rate, reduce stability, etc., to improve construction safety and labor efficiency , avoid the rotation is not in place, reduce the effect of frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further explained below in conjunction with the accompanying drawings.

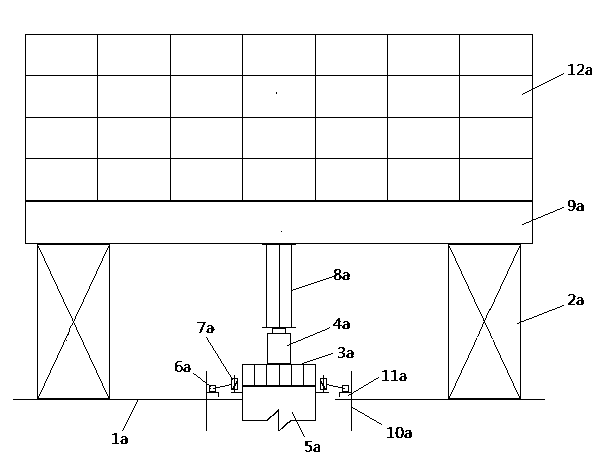

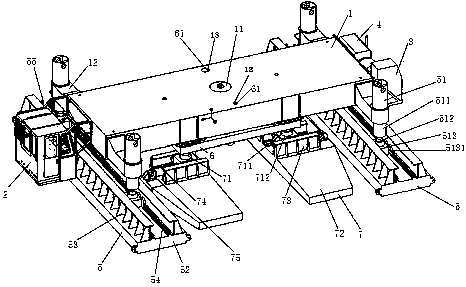

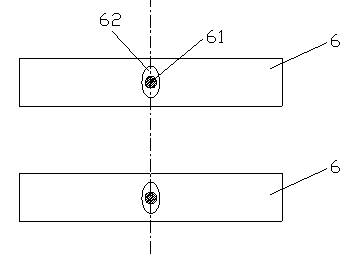

[0060] see Figure 2~Figure 4 , a ground foundation anti-compression static load test system, comprising: a platform 1 for carrying ballast, a main measuring oil cylinder 11 is arranged in the middle of its upper end, and a two-way port is respectively opened at the positions on both sides of the main measuring oil cylinder of the platform. Holes 13; the driver's cab 2 arranged on one side of the platform, the engine group 4 and the motor hydraulic pump 3 arranged on the other side of the platform; the driver's cab 2 is connected with the motor hydraulic pump 3 through the engine group 4; The rotating platform 6 is provided with a blind hole 62 in the middle, and a connecting shaft 61 corresponding to the through hole 13 of the platform 1 is arranged in the blind hole 62, and the rotating platform 6 is connected with the platform 1 through the connecting shaft 61; The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com