Method for detecting content of silicon in aluminum alloy based on developing technique

A technology of silicon content and aluminum alloy, which is applied in the detection field of silicon content in aluminum alloy, can solve problems such as reliability and accuracy without data support, whether it takes a long time for complete color development, and inaccurate measurement results, etc., to achieve reagent Fewer varieties, shorten the detection cycle, and solve the effect of interference problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

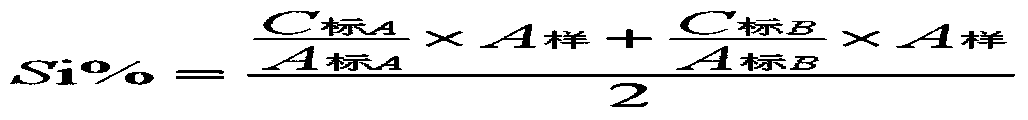

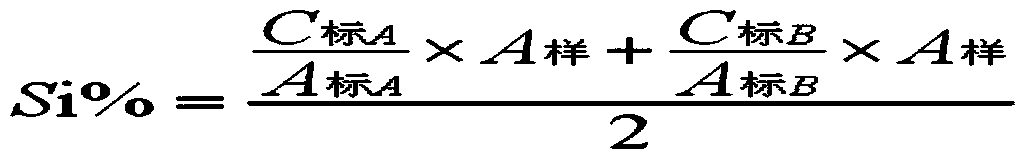

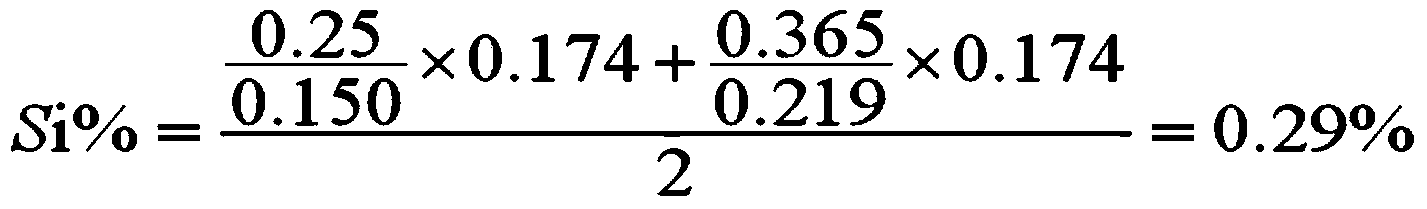

[0045] [Example 1] The detection method of the silicon content in the aluminum alloy based on the chromogenic technology, it comprises a step of measuring the absorbance value of the standard sample solution and the sample solution respectively with a spectrophotometer and a calculation of the silicon content value in the sample solution A step of:

[0046] S1: Preparation of solution, including preparation of sample solution and preparation of standard solution;

[0047] Wherein, the preparation steps of sample solution are:

[0048] S11: Weigh the sample and place it in a silver beaker. Assuming that the silicon content in the sample is 0.1% to 0.35%, the weighing amount of the sample is: 0.0500g, add 15mL of 25% sodium hydroxide to the silver beaker and heat to dissolve , cooled to room temperature with running water, and transferred to a 100mL steel measuring bottle filled with 15mL (1+1) nitric acid in advance;

[0049] S12: Add 1mL of 1% sodium nitrite to the steel mea...

Embodiment 2

[0061] [Example 2] The detection method of silicon content in aluminum alloy based on color development technology, it includes a step of measuring the absorbance value of the standard sample solution and the sample solution respectively with a spectrophotometer and a calculation of the silicon content value in the sample solution A step of:

[0062] S1: Preparation of solution, including preparation of sample solution and preparation of standard solution;

[0063] Wherein, the preparation steps of sample solution are:

[0064] S11: Weigh the sample and place it in a silver beaker. Assuming that the silicon content in the sample is 0.45% to 0.65%, the weighing amount of the sample is: 0.0550g, add 10mL of 30% sodium hydroxide to the silver beaker and heat to dissolve , cooled to room temperature with running water, and transferred to a 100mL steel measuring bottle filled with 19mL (1+1) nitric acid in advance;

[0065] S12: Add 2 mL of 1% sodium nitrite to the steel measurin...

Embodiment 3

[0077] [Example 3] The detection method of silicon content in aluminum alloy based on color development technology, it includes a step of measuring the absorbance value of the standard sample solution and the sample solution respectively with a spectrophotometer and a calculation of the silicon content value in the sample solution A step of:

[0078] S1: Preparation of solution, including preparation of sample solution and preparation of standard solution;

[0079] Wherein, the preparation steps of sample solution are:

[0080] S11: Weigh the sample and place it in a silver beaker. Assuming that the silicon content in the sample is 0.72% to 1%, the weighing amount of the sample is: 0.0600g, add 15mL of 35% sodium hydroxide to the silver beaker and heat to dissolve , cooled to room temperature with running water, and transferred to a 100mL steel measuring bottle filled with 20mL (1+1) nitric acid in advance;

[0081] S13: Add 3 mL of 1% sodium nitrite to the steel measuring b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com