Method and device for regenerating casting sand of lost foam casting production line

A technology of lost foam casting and regeneration device, which is applied in the direction of casting molding equipment, cleaning/processing machinery of casting mold materials, manufacturing tools, etc. It can solve the problems of low cooling efficiency of hot sand, harsh working environment, large occupied area and space, etc. problems, to achieve the effect of improving the working environment and working conditions, improving operating efficiency, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

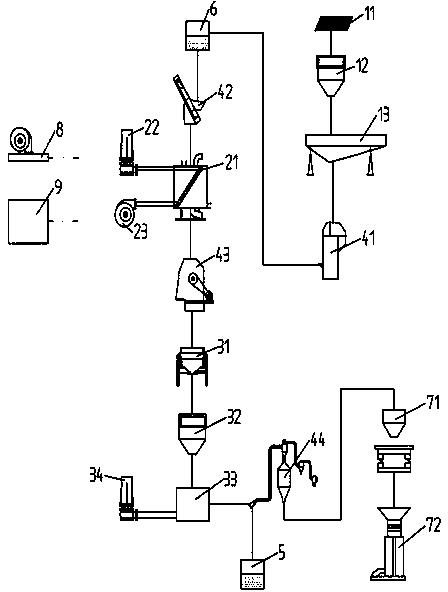

[0034] The molding sand regeneration device includes a sand filling system 10, ash removal and cooling system 20, a sand selection system 30, a sand delivery system 40, a central sand storage 5, an intermediate sand storage 6, a control system 70, and a dust removal system 80. The sand delivery system 40 is composed of four conveying devices. The falling sand filling system 10 is connected to the intermediate sand storage 6 through the bucket elevator 41. The intermediate sand storage 6 is connected to the ash removal cooling system 20 through the bucket elevator 42. The ash removal cooling system 20 is connected with the sand selection system 30 through the bucket elevator 43, the sand selection system 30 is connected with the central sand storage 5 and the sand filling system 10 through the bucket elevator 44, and the dust removal system 80 is connected with the sand filling system 10. Ash removal and cooling system 20, sand selection system 30, sand delivery system 40, centr...

Embodiment 2

[0044] The molding sand regeneration device includes a sand filling system 10, ash removal and cooling system 20, a sand selection system 30, a sand delivery system 40, a central sand storage 5, an intermediate sand storage 6, a control system 70, and a dust removal system 80. The sand delivery system 40 is composed of four conveying devices. The falling sand filling system 10 is connected to the intermediate sand storage 6 through the bucket elevator 41. The intermediate sand storage 6 is connected to the ash removal cooling system 20 through the bucket elevator 42. The ash removal cooling system 20 is connected with the sand selection system 30 through the bucket elevator 43, the sand selection system 30 is respectively connected with the central sand storage 5 and the sand filling system 10 through the pneumatic conveying device 44, and the dust removal system 80 is connected with the sand filling system 10 , ash removal and cooling system 20, sand selection system 30, sand ...

Embodiment 3

[0054]The molding sand regeneration device includes a sand filling system 10, ash removal and cooling system 20, a sand selection system 30, a sand delivery system 40, a central sand storage 5, an intermediate sand storage 6, a control system 70, and a dust removal system 80. The sand delivery system 40 is composed of four conveying devices. The falling sand filling system 10 is connected to the intermediate sand storage 6 through the bucket elevator 41. The intermediate sand storage 6 is connected to the ash removal cooling system 20 through the bucket elevator 42. The ash removal cooling system 20 is connected with the sand selection system 30 through the bucket elevator 43, the sand selection system 30 is connected with the central sand storage 5 and the sand filling system 10 through the bucket elevator 44, and the dust removal system 80 is connected with the sand filling system 10. Ash removal and cooling system 20, sand selection system 30, sand delivery system 40, centra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com