High-performance powder metallurgy oil-containing bearing and manufacturing method thereof

A powder metallurgy and manufacturing method technology, applied in the field of high-performance powder metallurgy oil-impregnated bearings and their manufacturing, can solve problems such as low bonding strength, environmental pollution, excessive wear, etc., to improve sintering performance, reduce sintering temperature, and reduce formation. effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

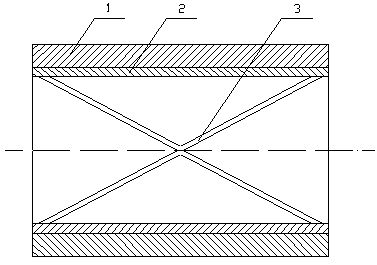

[0025] like figure 1 As shown, the high-performance powder metallurgy oil-impregnated bearing of the present invention is formed by sintering and compounding a steel sleeve 1 and a copper alloy layer 2 . The copper alloy layer 2 is formed by pressing powder metallurgy copper powder, and it is placed inside the steel sleeve 1 . The inner wall of the copper alloy layer 2 is provided with an oil groove 3 (or an oil hole or other structure that is beneficial to lubrication). The oil-impregnated bearing of the present invention is manufactured by the following three methods of embodiment (the process steps of the three embodiments are the same, but the composition ratio of the copper alloy powder is different):

[0026] 1. Mixing: Put the powder into the mixing tank according to the ratio in the table below for mixing, and the mixing time is 2 hours.

[0027] Copper alloy powder composition ratio table (unit: weight content %)

[0028] Embodiment one Embodimen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com