Electrophoresis and supersonic vibration assisted micro-milling and machining device

An ultrasonic vibration, micro-milling technology, applied in metal processing equipment, milling machine equipment, manufacturing tools, etc., can solve the problems of low processing efficiency, tool wear, inability to process hard and brittle materials, etc., to improve processing efficiency and improve cutting characteristics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

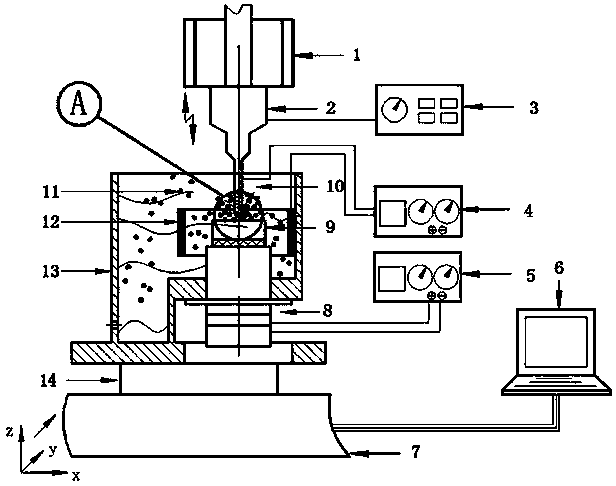

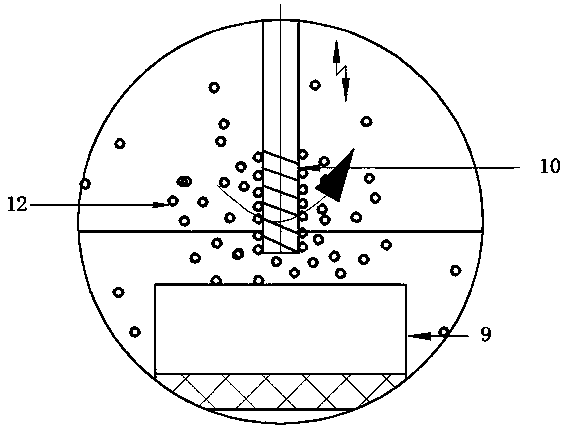

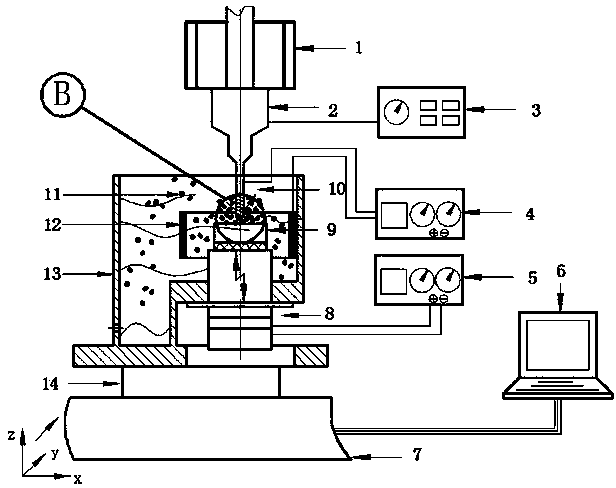

[0023] The structure diagram of the present invention is as figure 1 , 2 , 3, and 4, the electrophoresis and ultrasonic vibration assisted micro-milling processing device of the present invention includes a vertical slider 1, a micro-ultrasonic spindle 2, a micro-ultrasonic spindle power generator and a control panel 3, an electrophoresis auxiliary power supply 4, a micro Ultrasonic platform power generator and control panel 5, motion control system 6, micro three-dimensional motion platform 7, micro ultrasonic platform 8, workpiece 9, milling cutter 10, ultrafine abrasive particles 11, electrophoresis auxiliary circular electrode 12, working fluid tank 13 , the milling cutter 10 is installed on the rotatable micro-ultrasonic main shaft 2 through a fixture, and the micro-ultrasonic main shaft 2 is closely connected with the micro-ultrasonic main shaft 2 through a special fixture, and the micro-ultrasonic main shaft 2 is installed on the vertical sliding table 1. Type sliding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com