A method for making high wear-resistant glazing anti-counterfeiting packaging box

A packaging box, high wear-resistant technology, applied in the direction of packaging, transportation and packaging, box production operations, etc., can solve the problems of printing that the finished product is not suitable for packaging, poor smoothness, rough pores, etc., to achieve good wear resistance, Strong product stiffness and folding resistance, good finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

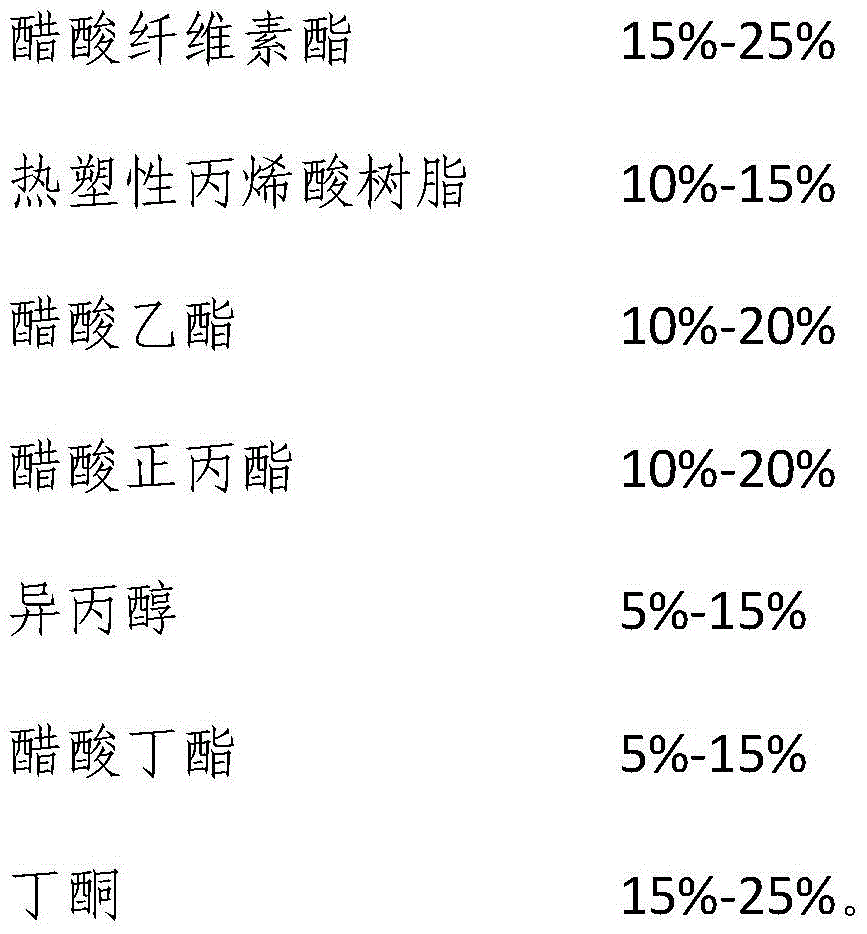

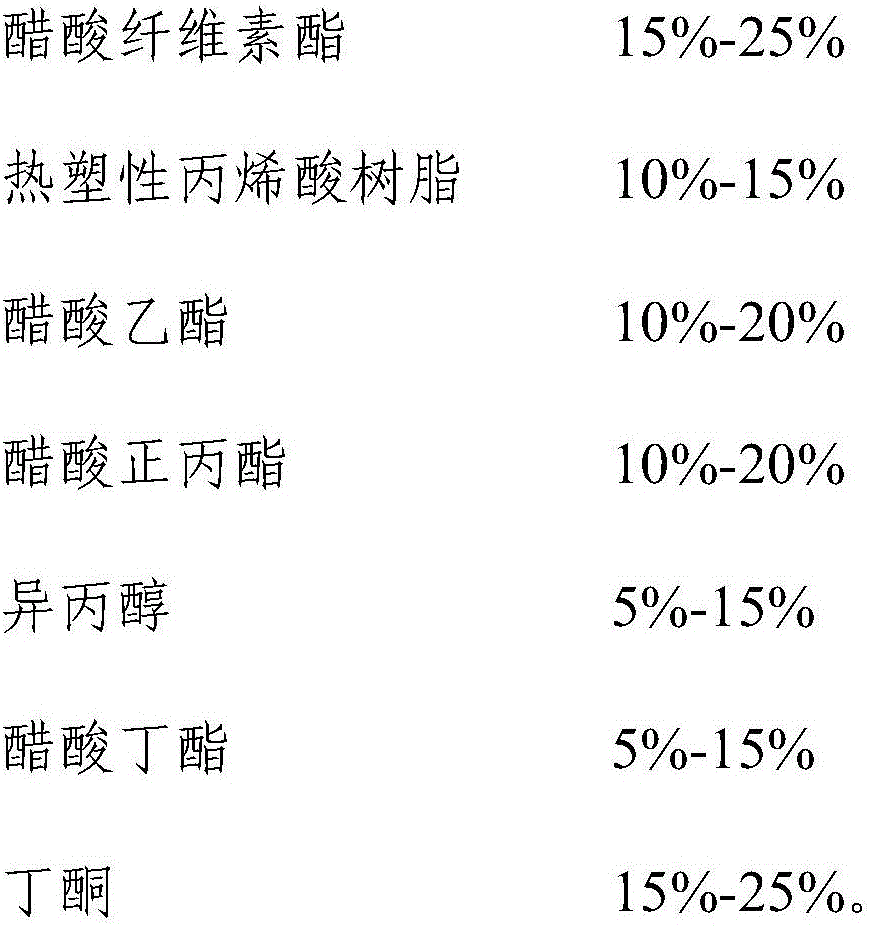

[0021] The formulation of the glazing coating is shown in the table below (unit: parts by weight)

[0022]

Example 1

Example 2

Example 3

Example 4

Example 5

Cellulose acetate

15

20

25

20

15

15

10

10

8

13

20

15

15

12

12

15

10

20

20

15

Isopropanol

5

15

10

14

5

5

15

10

13

5

25

15

10

13

25

[0023] Among them, cellulose acetate and thermoplastic acrylic resin can be selected from commercially available industrial products.

[0024] The method for making the high wear-resistant glazing anti-counterfeiting packaging box comprises the following steps:

[0025] 1) Select the base paper, evenly coat the primer coating on the coated surface of the base paper and perform drying treatment; 2) prepare the glazing layer coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com