Preparation process of hydrogen-rich water

A preparation process, hydrogen-rich water technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Sexual difference and other problems, to achieve the effect of inhibiting human aging and inhibiting high blood pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

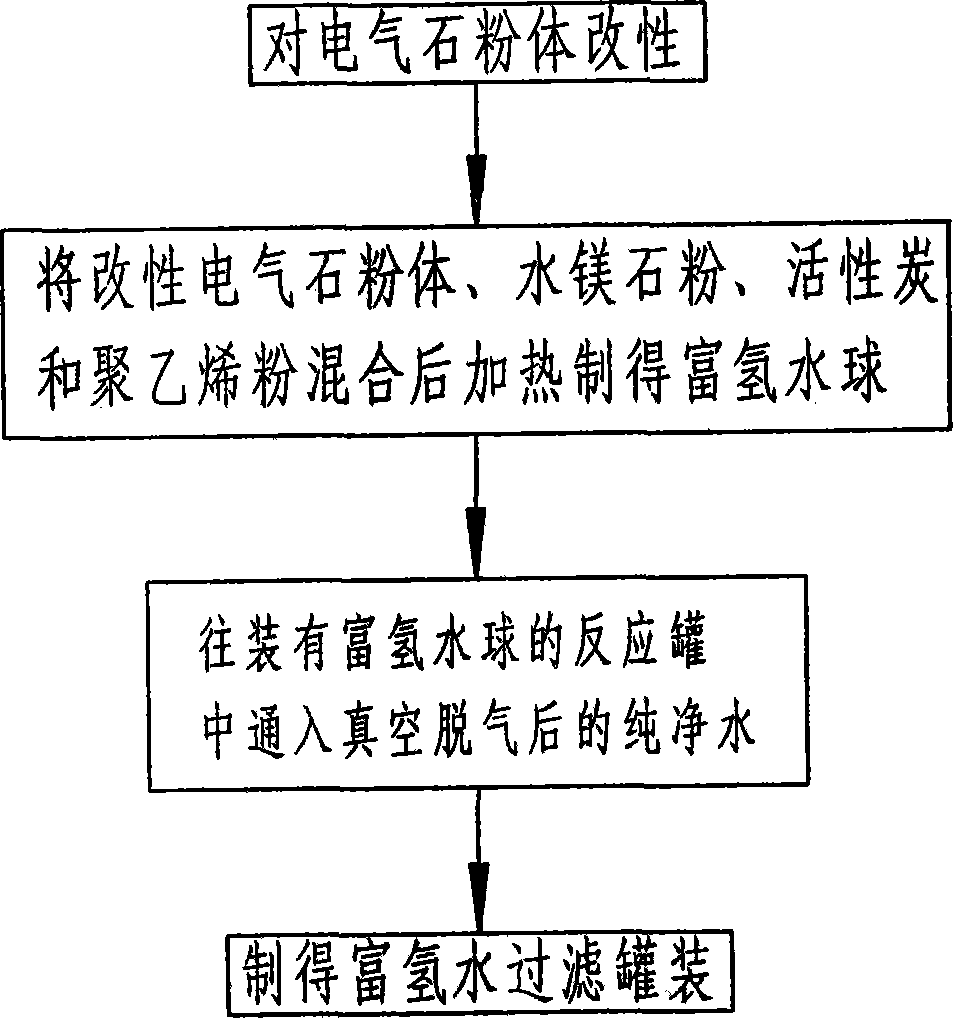

Method used

Image

Examples

Embodiment 1

[0018] Add polyvinyl alcohol 1788 to the tourmaline powder and stir at room temperature to prepare a modifier with a mass fraction of 0.4% of the tourmaline powder. The slurry with a mass fraction of 15% is put into a heating device with a temperature of 50 ° C and stirred for 10 minutes, and then used; A modified tourmaline powder solution is prepared, and the modified tourmaline powder solution is filtered and dried to prepare a modified tourmaline powder, which is used for later use.

[0019] The composition weight percentage of each component in the hydrogen-rich water mixture is as follows: 59% of the spare modified tourmaline powder, 20% of the brucite powder directly purchased from the market, 15% of activated carbon, and 6% of polyethylene powder. The sum of the components by weight is 100%; the hydrogen-rich water mixture is put into a heating device with a temperature of 120 ° C and heated for 30-40min to obtain a 2-4mm hydrogen-rich water ball, and the obtained hydr...

Embodiment 2

[0021] Add polyvinyl alcohol 1788 to the tourmaline powder and stir to prepare a modifier with a mass fraction of 0.3% of the tourmaline powder at room temperature. The slurry with a mass fraction of 25% is put into a heating device with a temperature of 55 ° C and stirred for 15 minutes, and then used for standby; A modified tourmaline powder solution is prepared, and the modified tourmaline powder solution is filtered and dried to prepare a modified tourmaline powder, which is used for later use.

[0022] The weight percentage of each component in the hydrogen-rich water mixture is as follows: 50% of the spare modified tourmaline powder, 28% of the brucite powder, 16% of activated carbon, and 6% of polyethylene powder purchased directly from the market. The sum of the components by weight is 100%; the hydrogen-rich water mixture is put into a heating device with a temperature of 125 ° C and heated for 30-40min to obtain a 2-4mm hydrogen-rich water ball, and the obtained hydr...

Embodiment 3

[0024] Add polyvinyl alcohol 1788 to the tourmaline powder and stir to prepare a modifier with a mass fraction of 0.7% of the tourmaline powder at room temperature. The slurry with a mass fraction of 20% is placed in a heating device with a temperature of 53 ° C and stirred for 28 minutes, and then used for standby; A modified tourmaline powder solution is prepared, and the modified tourmaline powder solution is filtered and dried to prepare a modified tourmaline powder, which is used for later use.

[0025] The weight percentage of each component in the hydrogen-rich water mixture is as follows: 55% of the spare modified tourmaline powder, 20% of the brucite powder, 17% of activated carbon, and 8% of polyethylene powder purchased directly from the market. The sum of the components by weight is 100%; the hydrogen-rich water mixture is put into a heating device with a temperature of 130 ° C and heated for 30-40min to obtain a 2-4mm hydrogen-rich water ball, and the obtained hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com