Preparation method of 2-deoxy-D-glucose

A technology of glucose and glucosinolate, which is applied in the chemical field, can solve the problems of non-environmental protection and economy, troublesome operation, high cost, etc., and achieve the effect of simple and clear method, low cost and less raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

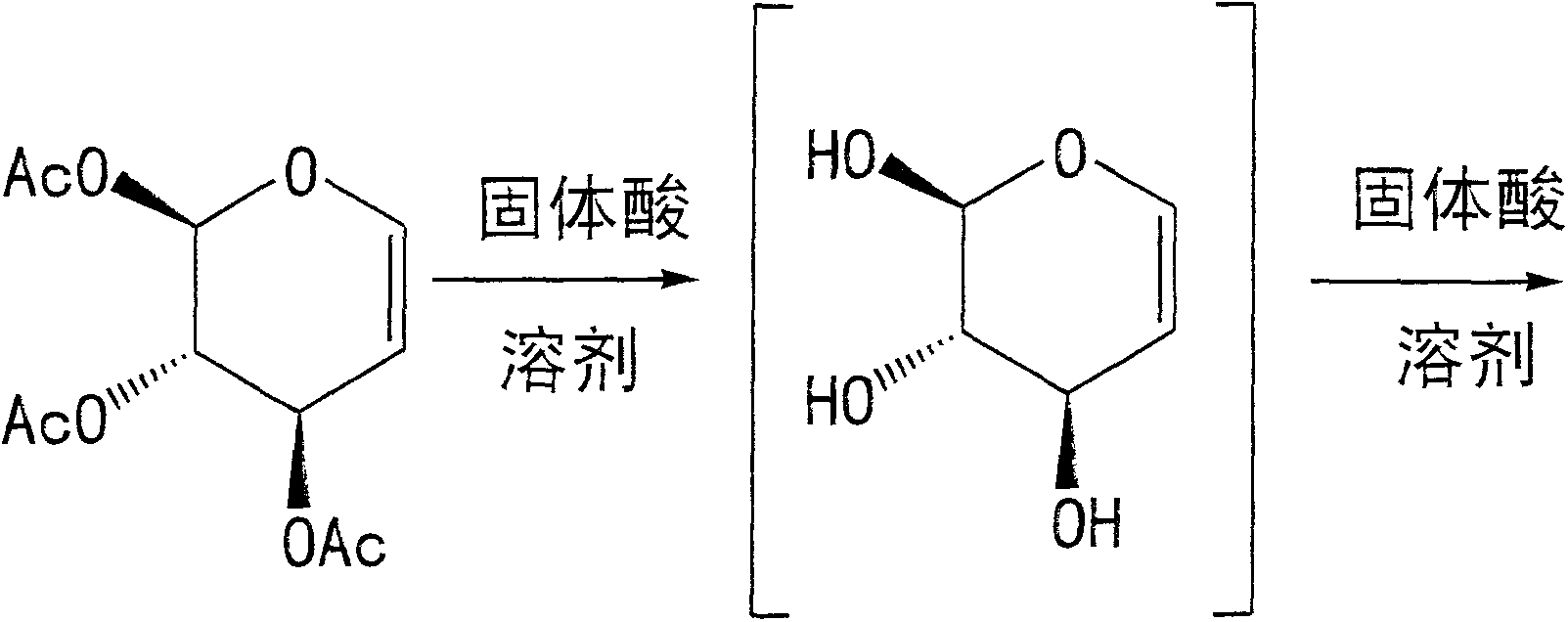

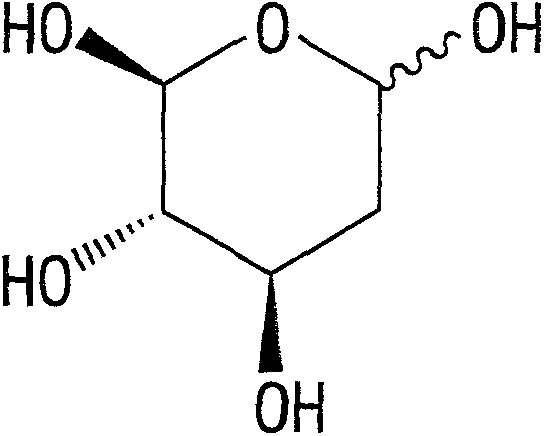

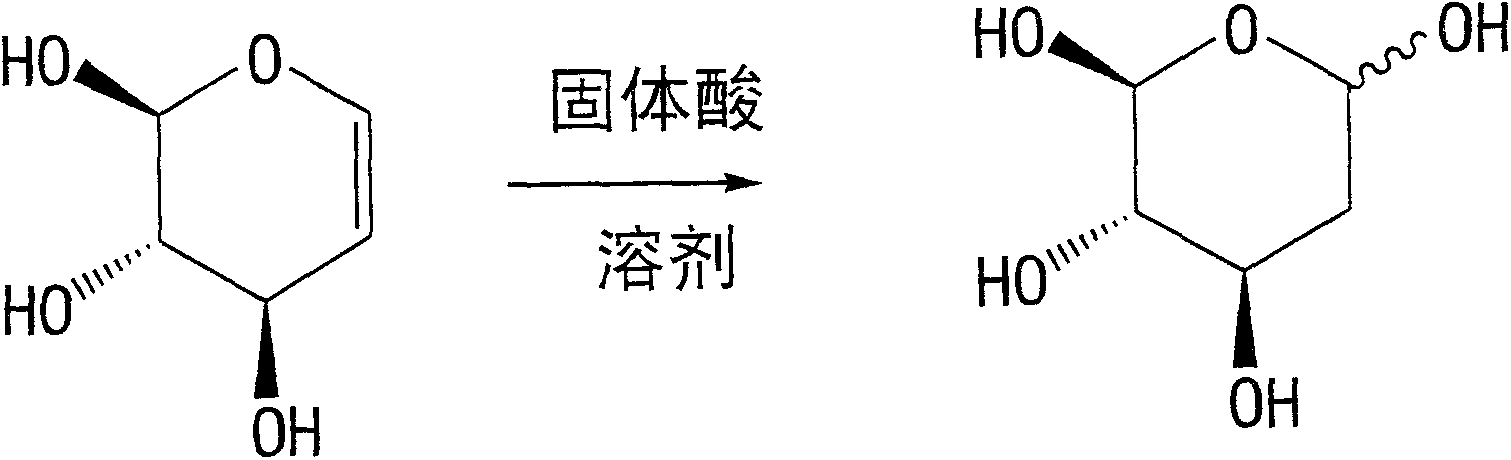

Method used

Image

Examples

Embodiment 1

[0031] Add 150 ml of purified water, 10 g of cationic resin, 25.8 g of 3,4,5-tri-O-acetyl D-glucal (0.10 mol) into a 250 ml reaction bottle, react at 25°C-30°C for 24 hours, filter , wash the resin with water, combine the filtered solution and the washing solution, add 1.0 g of medicinal activated carbon to decolorize at room temperature, filter, and concentrate the filtered solution under reduced pressure below 50 ° C, then add 250-350 ml of acetone for recrystallization, filter, and wash with a small amount of acetone , the solid was dried under reduced pressure and vacuum to obtain 11.28 g of 2-deoxy-D-glucose, with a yield of 75.20%.

Embodiment 2

[0033] Add 150 milliliters of purified water, 10 grams of cationic resin, 13.2 grams of 3,4,5-tri-hydroxy-D-glucal (0.10mol) into a 250 milliliter reaction bottle, react at 25°C-30°C for 15 hours, filter, Wash the resin with water, combine the filtered solution and the washing solution, concentrate the filtered solution under reduced pressure below 50°C, then add 250-350 ml of acetone to recrystallize, filter, wash with a small amount of acetone, and dry the solid under vacuum to obtain 2-deoxy-D - Glucose 12.32 grams, yield 82.13%.

[0034] The melting point is 144-147°C.

[0035] H NMR (D 2 O, 400MHz): 4.93(d, 1H), 3.91(d, 1H), 3.g8(d, 1H), 3.81(d, 1H), 3.69-3.74(m, 4H), 3.37-3.41(m, 1H), 3.28(t, 6H), 1.46-1.55(m, 2H).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com