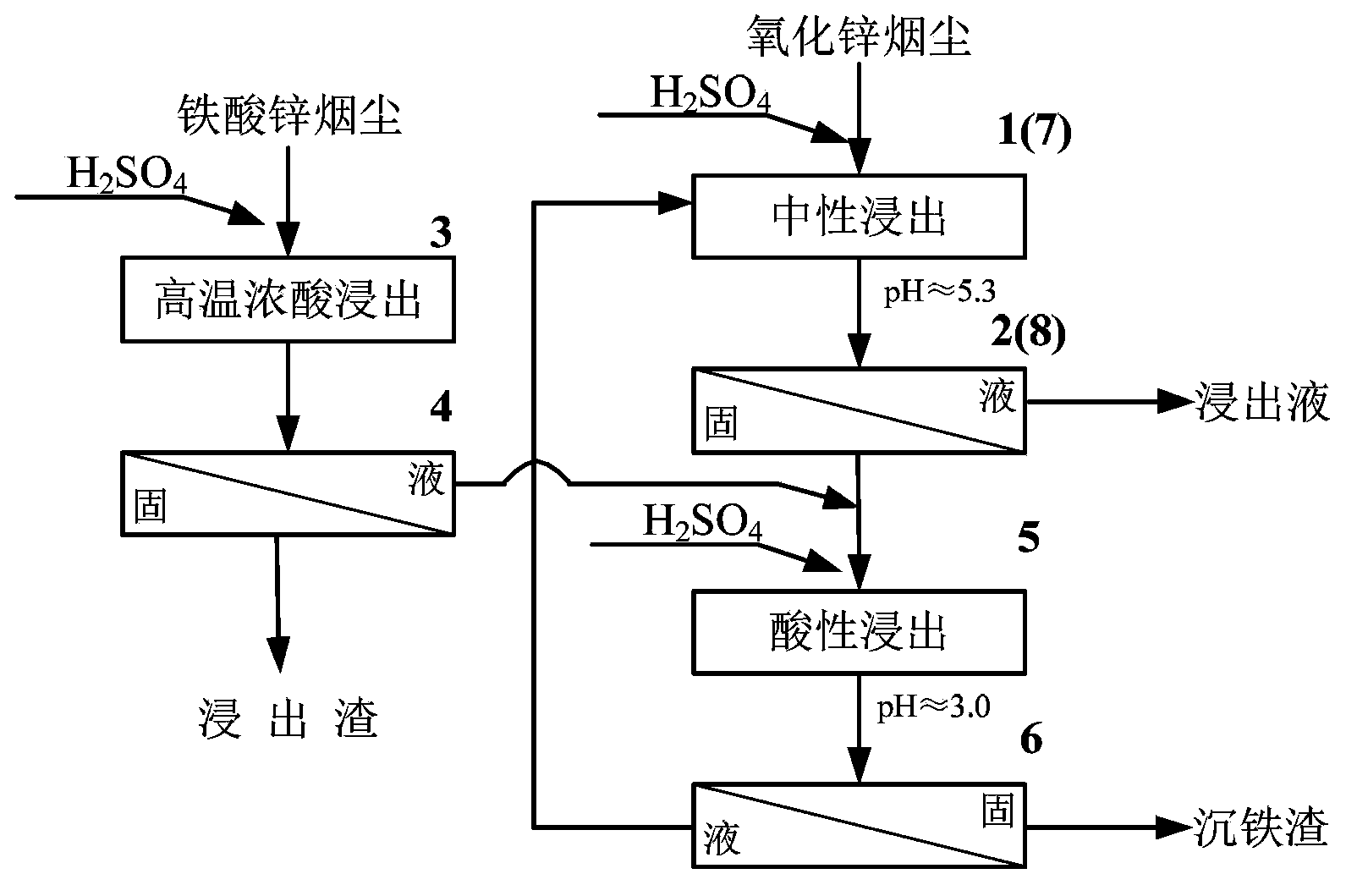

Method for efficiently fully leaching zinc from dust caused by making steel from waste galvanized plates

A technology for leaching and fumes, which is applied in the field of efficiently and fully leaching zinc from waste galvanized steelmaking fumes, can solve the problems of increased processing costs, low leaching efficiency, waste of zinc resources, etc., and achieves cost savings, quick results, and initial investment little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This process is used to treat waste galvanized sheet steelmaking smoke and dust in a steel factory in Suzhou. Due to the difference of raw materials into the furnace, the soot is mainly composed of zinc oxide, containing about 10% zinc and about 15% iron; or mainly zinc ferrite, containing about 20% zinc and about 22% iron. It is -0.074mm87%.

[0048] Using the traditional room temperature leaching process, the leaching rate of zinc oxide soot is about 90%; however, the leaching rate of zinc ferrite soot is only 50%, resulting in a large waste of resources. Using high-temperature concentrated acid leaching to treat zinc ferrite fume, the leaching rate can reach 90%, but the leaching solution contains a large amount of residual acid and iron ions, not only the waste of sulfuric acid is large, but also the cost of subsequent iron removal treatment is high, making it difficult to make profits.

[0049] Adopt the inventive method to process this flue dust:

[0050] (1) Ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com