Device and method for controlling oxygen content in liquid lead bismuth alloy

A liquid lead-bismuth alloy, control device technology, applied in various fluid ratio control and other directions, to achieve the effect of reducing residue and preventing oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

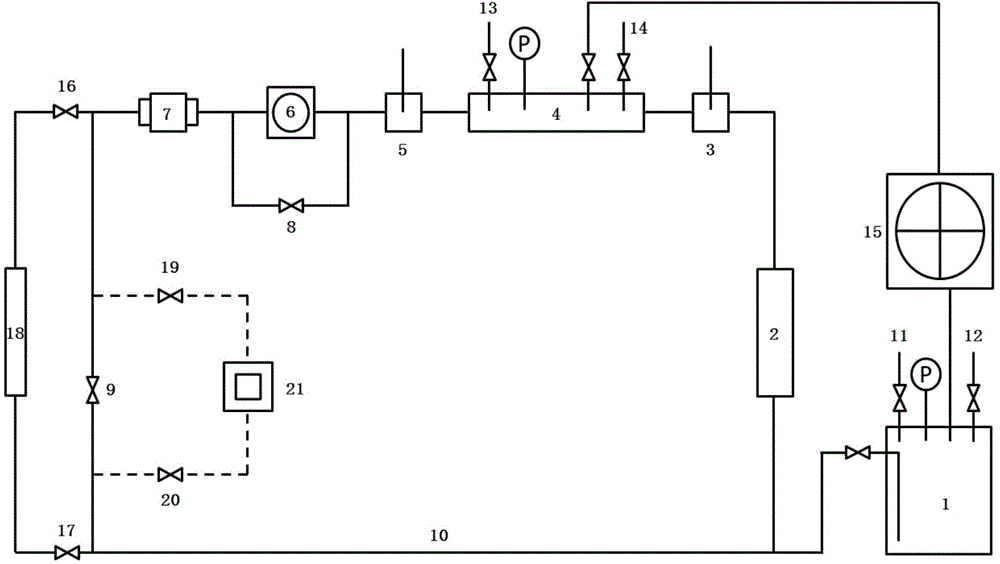

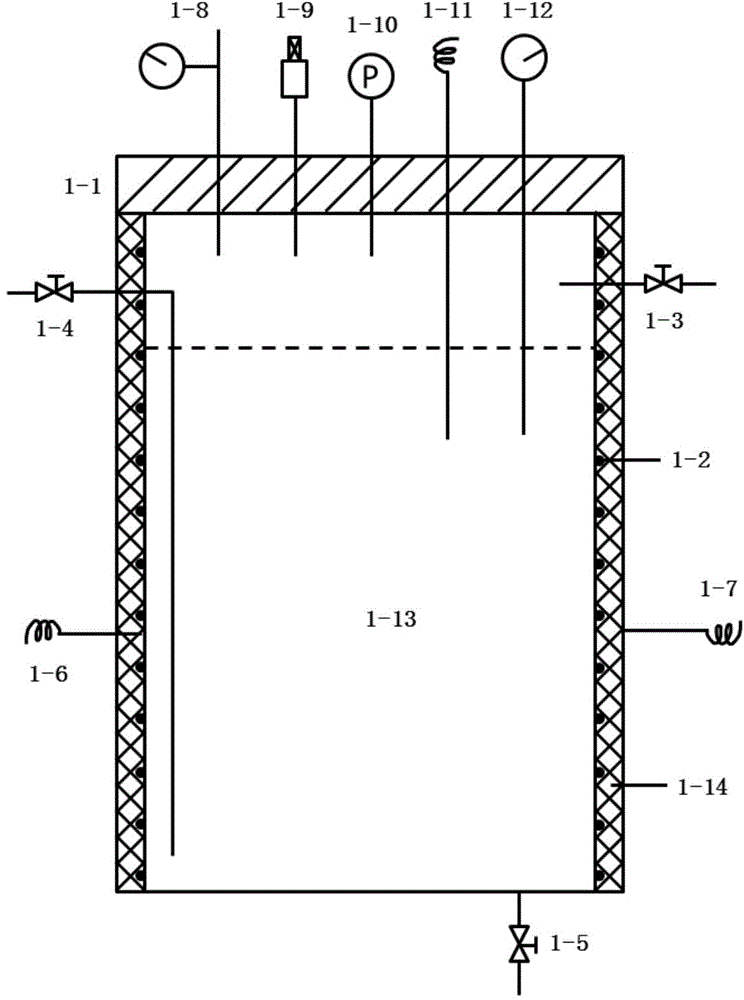

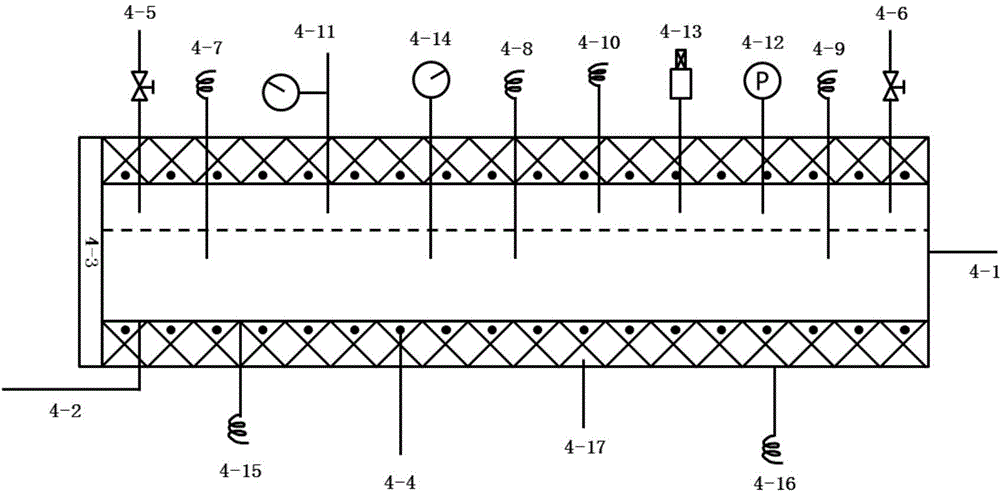

[0045] Example 1: see figure 1 , figure 2 , image 3 , Figure 4 , an oxygen content control device in a liquid lead-bismuth alloy, including a heating chamber 2 before the liquid inlet end of the oxygen content control chamber 4, the heating chamber is connected to a liquid metal mechanical pump 6 through the oxygen content control chamber 4, and the oxygen content The liquid inlet end of the control room 4 is provided with a liquid inlet oxygen probe 3, and a liquid outlet oxygen probe 5 is provided at the liquid outlet; the liquid metal flowmeter 7 is arranged at the outlet end of the liquid metal mechanical pump 6, and the liquid metal flowmeter 7 The outlet of the valve is connected to the liquid lead-bismuth alloy valve 9, and the return port of the liquid lead-bismuth alloy valve 9 communicates with the storage tank 1 through the return pipeline 10 and communicates with the heating chamber 2; Content control room4.

[0046] The storage tank 1 is provided with a sto...

Embodiment 2

[0053] Embodiment 2: A device for controlling the oxygen content in a liquid lead-bismuth alloy, which also includes an outlet end of the liquid metal flowmeter 7 connected to a corrosion chamber 18 through an inflow valve 16, and the corrosion chamber 18 is connected to a return pipeline through a return valve 17 10. All the other structures are the same as in Example 1.

Embodiment 3

[0054] Embodiment 3: A device for controlling the oxygen content in a liquid lead-bismuth alloy, which also includes an ADS system 21 with a liquid lead-bismuth alloy as a spallation target and a coolant at both ends of the liquid lead-bismuth alloy valve 9 , the inlet of the ADS system 21 using liquid lead-bismuth alloy as the spallation target and coolant is connected to the inlet port of the liquid lead-bismuth alloy valve 9 through the inlet valve 19, and its outlet is connected to the outlet port of the liquid lead-bismuth alloy valve 9 through the outlet valve 20 . All the other structures are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com