A solar cell welding strip dismantling device

A technology for solar cells and ribbons, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as difficult operation, falling corners of solar cells, enterprise losses, etc., to reduce damage factors, facilitate disassembly and operation, improve The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

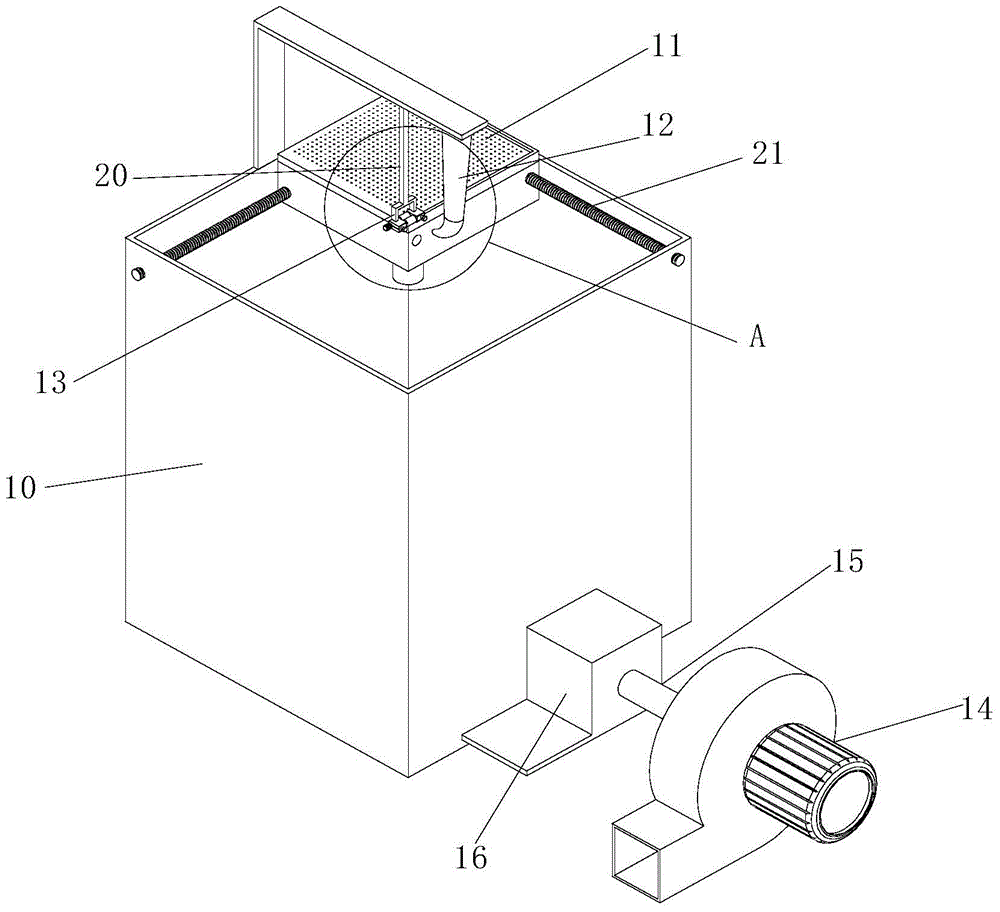

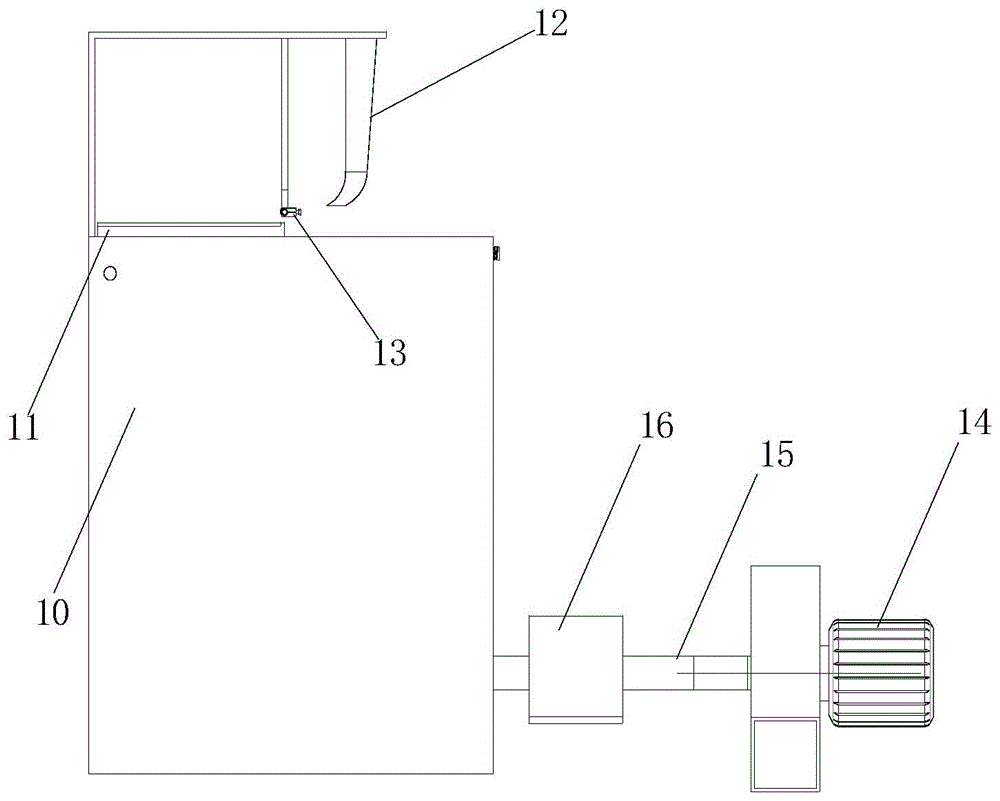

[0036] (1) the temperature of the heat gun 12, the moving speed and the moving track of the fixed platform 11 are set;

[0037] (2) open exhaust fan 14;

[0038] (3) step on foot switch 16 with one's feet, close exhaust fan 14 to the convulsion of fixed platform 11, at this moment there is no suction on fixed platform 11;

[0039] (4) Place the solar cells to be disassembled on the fixed platform 11, and the two sides of the cells are close to the two right-angled positioning edges of the fixed platform 11, so that the direction of the welding strip is parallel to the moving track of the heat gun 12;

[0040] (5) release the foot switch 16, the suction of the exhaust fan 14 will suck the solar cells to be disassembled;

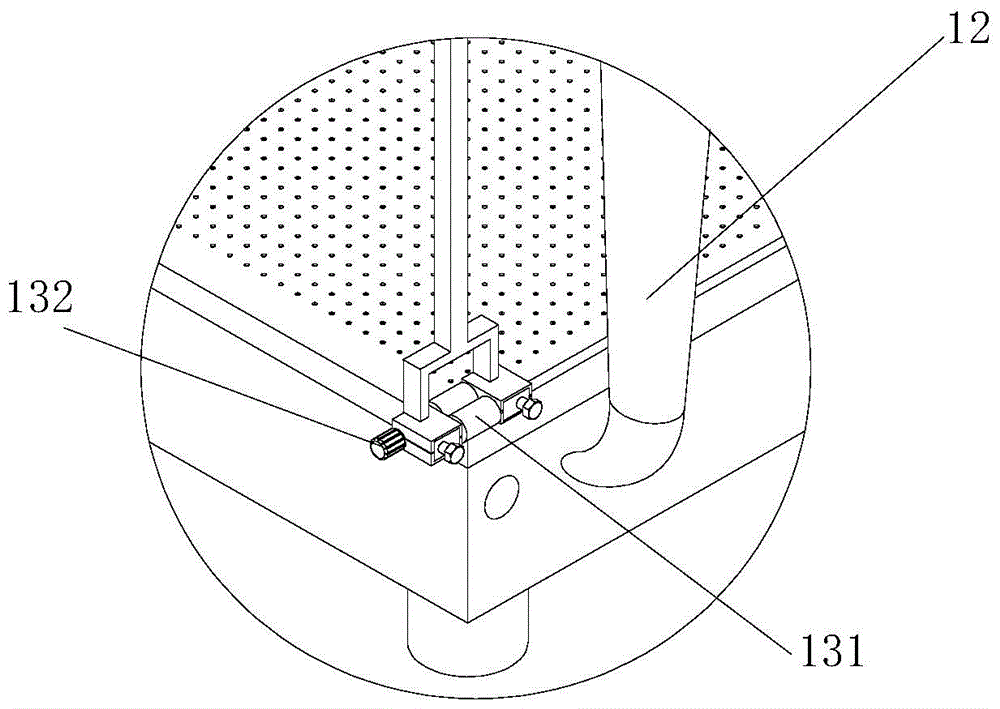

[0041] (6) Fix one end of the welding strip to be disassembled between the two non-metallic wheels 131 of the welding strip separation wheel 13 with tweezers;

[0042] (7) The heat gun 12 starts to heat, and rapidly heats the solder ribbon to be disassembled...

Embodiment 2

[0045] (1) take off the heat gun 12, set the temperature of the heat gun 12;

[0046] (2) open exhaust fan 14;

[0047] (3) step on foot switch 16 with one's feet, close exhaust fan 14 to the convulsion of fixed platform 11, at this moment there is no suction on fixed platform 11;

[0048] (4) Place the solar cells to be disassembled on the fixed platform 11;

[0049] (5) release the foot switch 16, the suction of the exhaust fan 14 will suck the solar cells to be disassembled;

[0050] (6) Use tweezers with one hand to hold one end of the ribbon to be disassembled, and hold the heat gun 12 with the other hand and heat it at the removal position of the ribbon;

[0051] (7) Gently apply force with the hand holding the tweezers to slowly separate the solder ribbon and the solar cell;

[0052] (8) The hand holding the heat gun 12 moves synchronously with the hand holding the tweezers to heat the welding strip at the dismounting position;

[0053] (9) After dismantling all the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com