Preparation method for interface self-assembly sulfonation graphene film

A technology of sulfonated graphene and self-assembly, applied in the direction of graphite, etc., can solve the problems of high production equipment requirements, inability to recycle, waste, etc., and achieve the effect of good cycle life performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

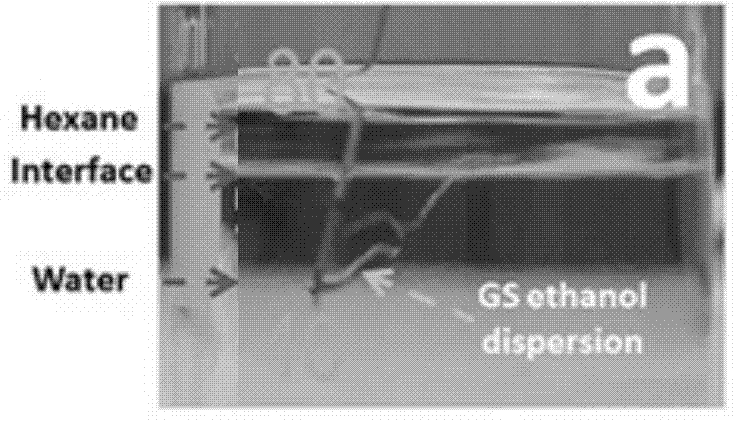

[0029] Load 40ml of deionized water in the beaker, and then carefully place 10ml of n-pentane on top of the deionized water to establish an oil-water interface;

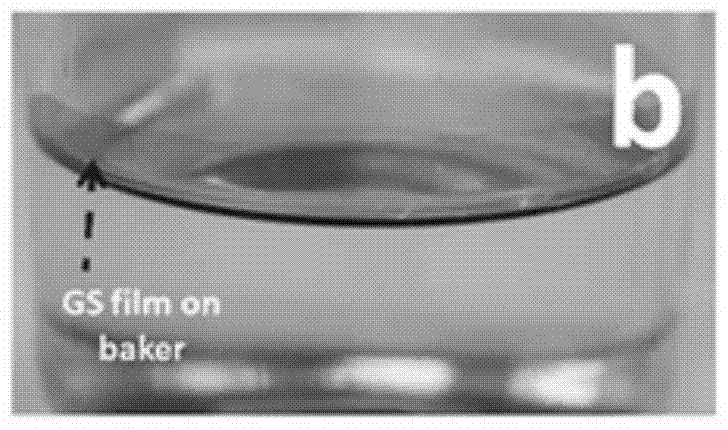

[0030] 10ml is injected into the aqueous phase of oil-water interface with methanol dispersed sulfonated graphene solution, and the concentration of sulfonated graphene in the sulfonated graphene solution is 0.05mg / ml, and the injection velocity of sulfonated graphene solution is 0.2ml / min, 20 minutes after the injection of the sulfonated graphene solution, use a syringe to suck away most of the oil layer, and let the rest volatilize naturally. The film is exposed, and the state of the film is as attached Figure 7 As shown in "e figure" in , the sulfonated graphene film completely covers the entire beaker;

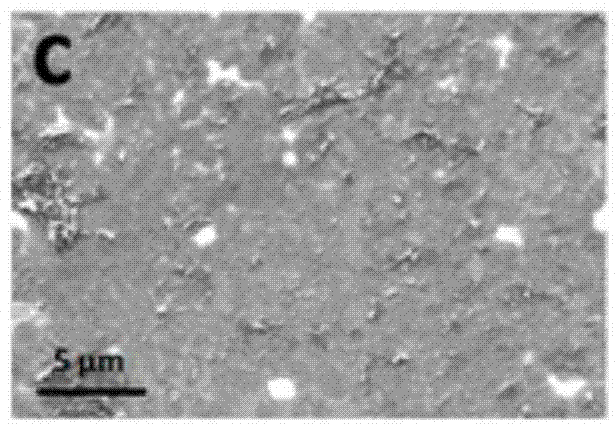

[0031] The quartz substrate was cleaned twice with ethanol and three times with acetone, and then pretreated with a mixed solution of sulfuric acid and hydrogen peroxide at a volume ratio of 4:1 for 30 minutes,...

Embodiment 2

[0035] Load 50ml of deionized water in the beaker, and then carefully place 12ml of n-pentane on top of the deionized water to establish an oil-water interface;

[0036] The sulfonated graphene solution that 12ml is dispersed with ethanol is injected in the water phase of oil-water interface, and the concentration of sulfonated graphene in the sulfonated graphene solution is 0.075mg / ml, and the injection velocity of sulfonated graphene solution is 0.4ml / min, 30 minutes after the injection of the sulfonated graphene solution, use a syringe to absorb most of the oil layer, and let the rest volatilize naturally. The film is exposed;

[0037] The quartz substrate was cleaned twice with ethanol and three times with acetone, and then pretreated with a mixed solution of sulfuric acid and hydrogen peroxide at a volume ratio of 4:1 for 30 minutes, and then vertically immersed in the self-assembled sulfonated graphite Graphene film solution, and then vertically pulled, the speed of imm...

Embodiment 3

[0040] The rest of the steps are the same as in Example 1, only the "quartz substrate" is replaced with a "slide glass", and finally the state of the transferred single-layer sulfonated graphene film is obtained as attached Figure 5 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com