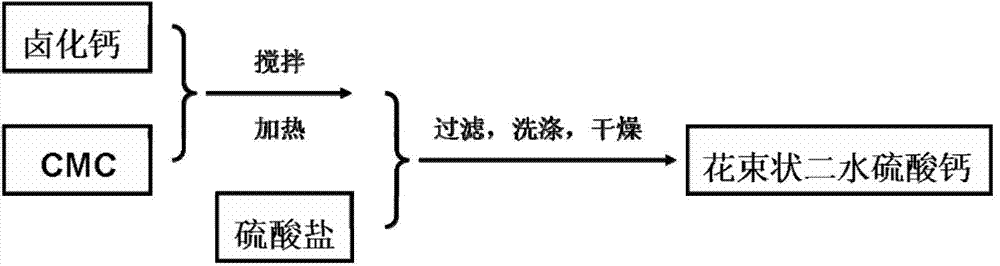

Preparation method of bunch-shaped calcium sulphate dihydrate

A calcium sulfate dihydrate, bouquet-like technology, applied in the direction of calcium/strontium/barium sulfate, etc., can solve the problems of gypsum microstructure change, affecting the performance of gypsum products, etc., and achieves convenient operation, high yield and simple synthesis route. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

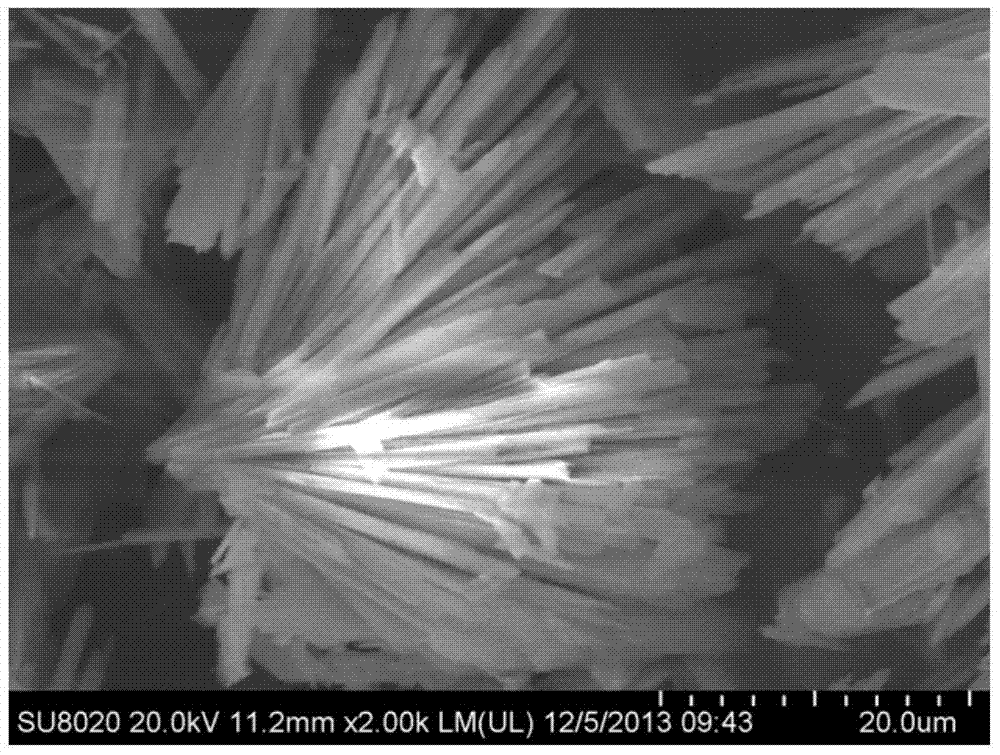

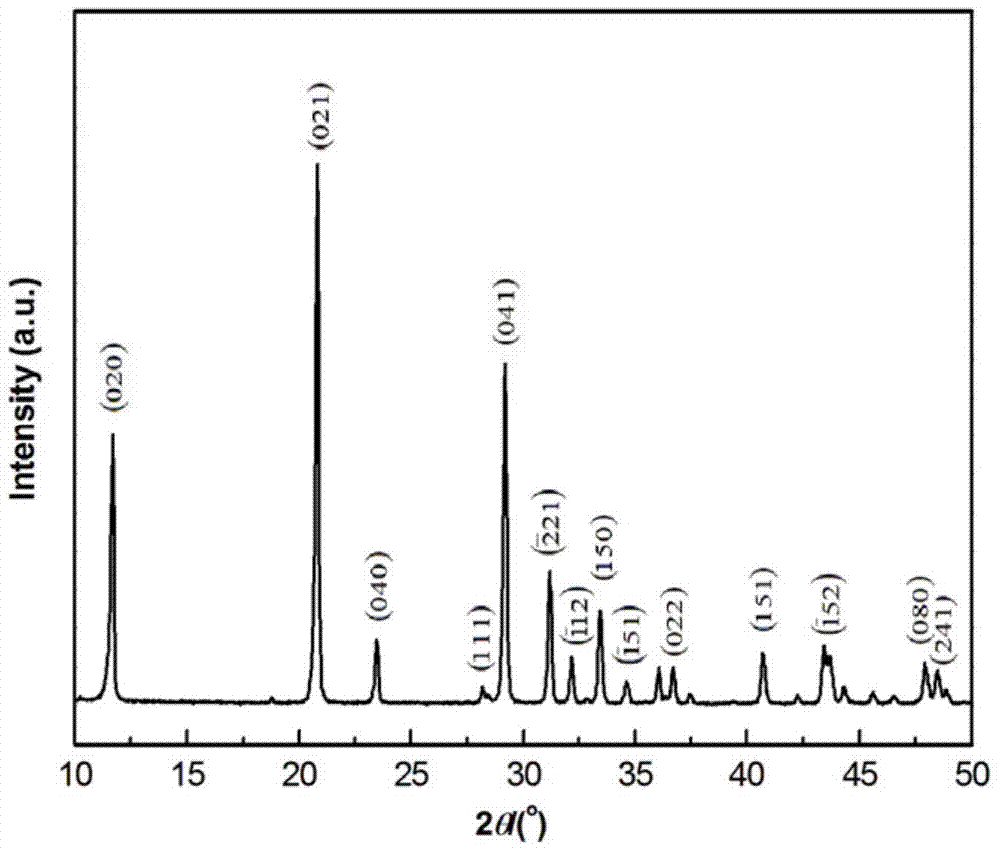

[0029] Prepare 0.2wt% sodium carboxymethylcellulose (CMC) solution with 500mL of deionized water, ultrasonically stir at 30°C for 0.5 hours, then add calcium chloride with an equivalent concentration of 0.1M, and continue stirring at 30°C for 0.5 hours; Then, potassium aluminum sulfate dodecahydrate with an equivalent concentration of 0.05M was stirred and added into the calcium chloride solution, and stirring was continued at 30°C until precipitation appeared, and filtered to obtain calcium sulfate dihydrate filter cake; the obtained calcium sulfate filter cake was added with ethanol and water Filter and rinse at room temperature, or filter the calcium sulfate filter cake obtained by drying at 60°C and add ethanol and water to filter and rinse at room temperature; dry the washed calcium sulfate filter cake at 50°C for 5 hours to obtain a bouquet-shaped calcium sulfate dihydrate .

[0030] A kind of bouquet-shaped calcium sulfate dihydrate phase that is prepared above is measu...

Embodiment 2

[0035] Prepare 0.4wt% sodium carboxymethylcellulose (CMC) solution with 1000mL of deionized water, ultrasonically stir at 50°C for 0.5 hours, then add calcium chloride with an equivalent concentration of 0.3M, and continue stirring at 50°C for 0.5 hours; then Stir and add potassium aluminum sulfate dodecahydrate with an equivalent concentration of 0.15M into the calcium chloride solution, continue stirring at 50°C until precipitation appears, and filter to obtain calcium sulfate dihydrate filter cake; add ethanol and water to the calcium sulfate filter cake obtained at room temperature Filter and rinse under water, or filter the calcium sulfate filter cake obtained by drying at 70°C and then add ethanol and water to filter and rinse at room temperature; dry the washed calcium sulfate filter cake at 80°C for 8 hours to obtain a bouquet-shaped calcium sulfate dihydrate.

[0036] A kind of bouquet-shaped calcium sulfate dihydrate phase that above-mentioned preparation obtains is m...

Embodiment 3

[0038] Prepare 0.5wt% sodium carboxymethylcellulose (CMC) solution with 5000mL of deionized water, ultrasonically stir at 80°C for 0.5 hours, then add calcium chloride with an equivalent concentration of 0.5M, and continue stirring at 80°C for 0.5 hours; then Stir and add potassium aluminum sulfate dodecahydrate with an equivalent concentration of 0.25M into the calcium chloride solution, continue stirring at 80°C until precipitation appears, and filter to obtain calcium sulfate dihydrate filter cake; add ethanol and water to the calcium sulfate filter cake obtained at room temperature Filter and rinse under water, or filter the calcium sulfate filter cake obtained by drying at 80°C and add ethanol and water to filter and rinse at room temperature; dry the washed calcium sulfate filter cake at 60°C for 10 hours to obtain a bouquet-shaped calcium sulfate dihydrate.

[0039] A kind of bouquet-shaped calcium sulfate dihydrate phase that above-mentioned preparation obtains is measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com