Preparation method of red silica-clad type cerium sulfate ceramic pigment

A technology of ceramic pigments and silica, applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve the problems such as the preparation method of silica-coated cerium sulfide ceramic pigments, etc. High temperature instability, low energy consumption and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

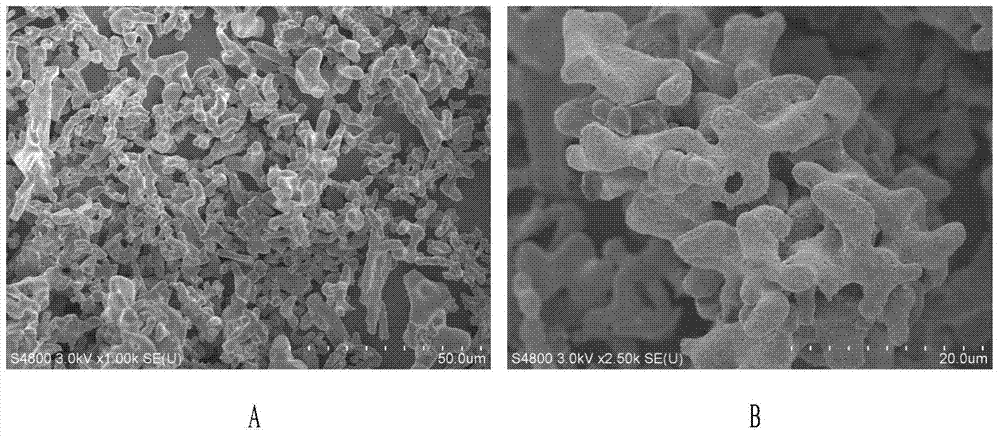

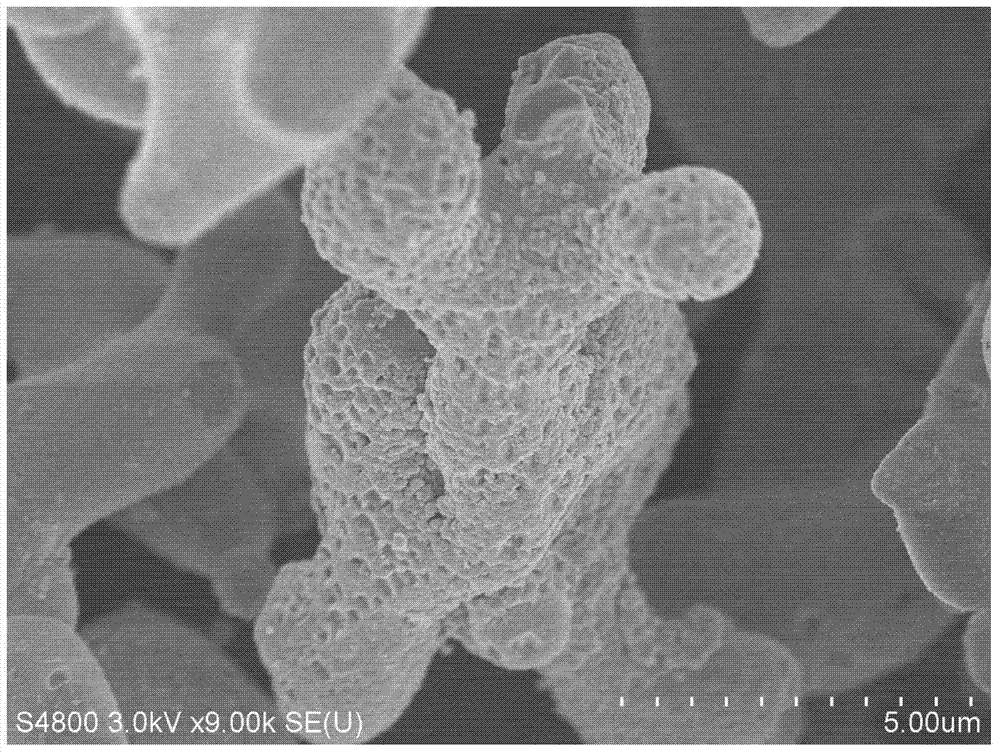

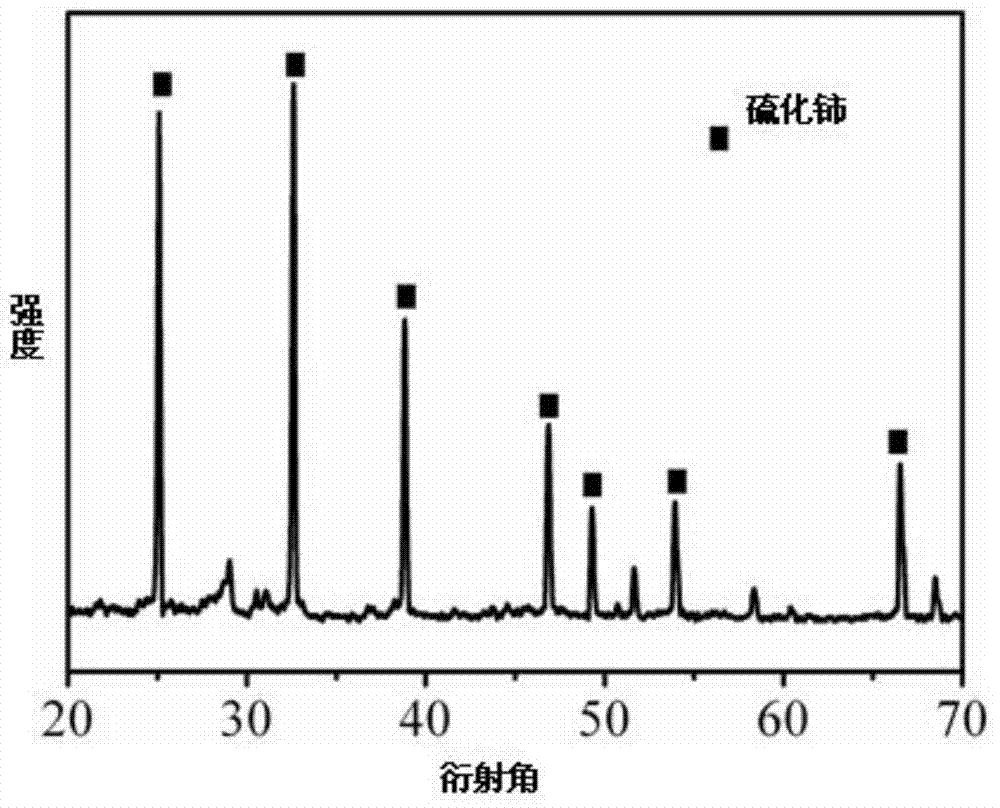

[0028] Grind the cerium sulfide red ceramic pigment with an agate mortar for 4 hours, then pass through a 120-mesh sieve, take the remaining part of the pigment on the sieve and ultrasonically clean it three times with absolute ethanol and deionized water, and dry it in a drying oven at 50°C for 8 hours. Obtain pretreated cerium sulfide. Prepare 200 mL of anhydrous ethanol solution of 0.024 mol / L ethyl orthosilicate, and stir thoroughly to obtain solution A. Disperse 0.25 g of the pretreated cerium sulfide red ceramic pigment obtained in step 1 in a mixed solution of 50 mL of ammonia water and absolute ethanol, stir thoroughly for 30 minutes, add polyvinylpyrrolidone dispersant to it and fully dissolve it under stirring to obtain Solution B. Wherein the volume fraction of ammonia in the mixed solution is 0.04, and the concentration of polyvinylpyrrolidone is 2g / L. The solution B was added to the solution A under the condition of thorough stirring, and the temperature was rai...

Embodiment 2

[0030] Grind the cerium sulfide red ceramic pigment with an agate mortar for 5 hours, then pass through a 120-mesh sieve, take the remaining part of the pigment on the sieve and ultrasonically clean it with absolute ethanol and deionized water for 3 times, and dry it in a drying oven at 50°C for 8 hours. Obtain pretreated cerium sulfide. Prepare 200 mL of an anhydrous ethanol solution of 0.048 mol / L ethyl orthosilicate, and stir thoroughly to obtain solution A. Disperse 0.5 g of the pretreated cerium sulfide red ceramic pigment obtained in step 1 in a mixed solution of 50 mL of ammonia water and absolute ethanol, stir thoroughly for 30 minutes, add polyvinylpyrrolidone dispersant to it and fully dissolve it under stirring to obtain Solution B. Wherein the volume fraction of ammonia in the mixed solution is 0.08, and the concentration of polyvinylpyrrolidone is 1g / L. The solution B was added to the solution A under the condition of thorough stirring, and the temperature was r...

Embodiment 3

[0032] Grind the cerium sulfide red ceramic pigment with an agate mortar for 6 hours, then pass through a 120-mesh sieve, take the remaining part of the pigment on the sieve and ultrasonically clean it with absolute ethanol and deionized water for 3 times, and dry it in a drying oven at 50°C for 8 hours. Obtain pretreated cerium sulfide. Prepare 200 mL of anhydrous ethanol solution of 0.072 mol / L ethyl orthosilicate, and stir thoroughly to obtain solution A. Disperse 1.0 g of the pretreated cerium sulfide red ceramic pigment obtained in step 1 in a mixed solution of 50 mL of ammonia water and absolute ethanol, stir thoroughly for 30 minutes, add polyvinylpyrrolidone dispersant to it and fully dissolve it under stirring to obtain Solution B. Wherein the volume fraction of ammonia in the mixed solution is 0.12, and the concentration of polyvinylpyrrolidone is 3g / L. The solution B was added to the solution A under the condition of thorough stirring, and the temperature was rais...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com