Passivation treatment agent for chrome-plated steel parts

A technology of passivation treatment and electroplating chromium, applied in the direction of metal material coating process, etc., can solve environmental pollution and other problems, achieve the effect of low concentration, low production cost, and easy wastewater treatment

Active Publication Date: 2016-05-18

ANHUI HUAXING METAL

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The traditional passivating agent contains carcinogenic hexavalent chromium, which causes serious pollution to the environment, and is gradually replaced by the environmentally friendly trivalent chromium passivating agent

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

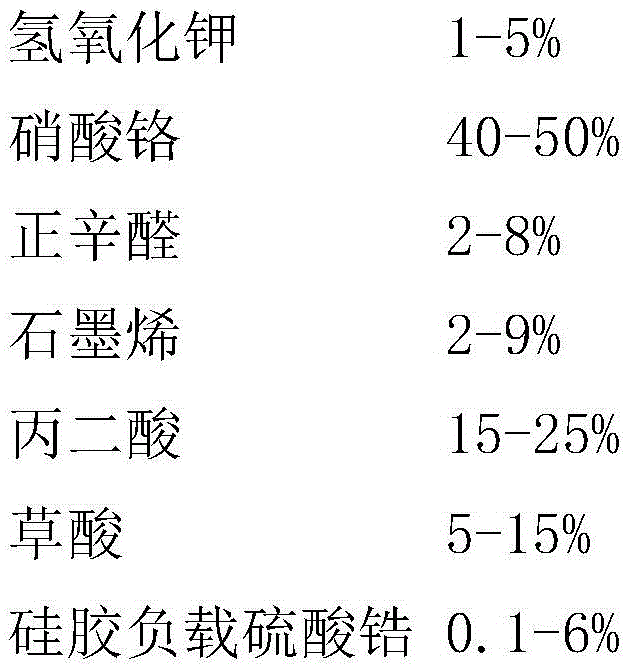

[0015] A passivation treatment agent for electrochrome-plated steel parts, consisting of the following components in mass percentage:

[0016]

[0017] The balance is tert-butanol.

Embodiment 2

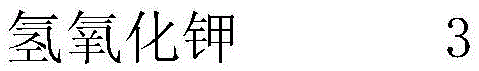

[0019] A passivation treatment agent for electrochrome-plated steel parts, consisting of the following components in mass percentage:

[0020]

[0021]

[0022] The balance is tert-butanol.

Embodiment 3

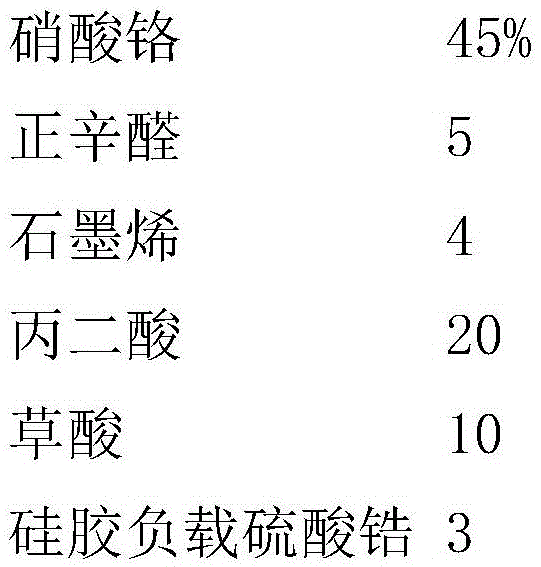

[0024]

[0025] The balance is tert-butanol.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a passivation treating agent for a chromium-plating steel part, and relates to the technical field of chemical engineering. The passivation treating agent comprises the following components in percentage by mass: 3% of potassium hydroxide, 45% of chromium nitrate, 5% of n-octanal, 4% of graphene, 20% of malonic acid, 10% of oxalic acid, 3% of silica gel-loading zirconium sulfate and the balance of tertiary butanol. The passivation treating agent provided by the invention is long in using period, does not contain hexavalent chromium and hydrogen peroxide or other strong oxidants, facilitates wastewater treatment and is an environment-friendly passivation agent. The passivation treating agent is low in concentration and production cost, relatively economic and practical and capable of improving the salt mist resistance and corrosion resistance of a metal surface and prolonging the service life of the steel part.

Description

technical field [0001] The invention relates to the technical field of chemical industry, in particular to a passivation treatment agent for electrochrome-plated iron and steel parts. Background technique [0002] Steel parts are usually passivated after chrome plating or hot chrome plating to prevent white rust in a short period of time. Because the chrome plating layer is easy to produce white rust in a humid environment, which seriously affects the appearance and service life, so steel parts usually need passivation treatment after chrome plating. The traditional passivating agent contains carcinogenic hexavalent chromium, causing serious pollution to the environment, and is gradually being replaced by the environmentally friendly trivalent chromium passivating agent. Early trivalent chromium passivators were made from chromic acid (Cr0 3 ) and reducing agent (such as potassium metabisulfite) reaction. Contents of the invention [0003] The technical problem to be so...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C23C22/62C25D5/48

Inventor 张福友

Owner ANHUI HUAXING METAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com