Full positive dispersion and full polarization maintaining optical fiber laser

A technology of polarization-maintaining fiber and total positive dispersion, which is applied in lasers, laser components, phonon exciters, etc., can solve the problem of increasing the difficulty of mode-locking adjustment of fiber lasers, destroying the full-fiber nature of fiber lasers, and the inability of mode-locking states of fiber lasers. Stability and other issues, to achieve the effect of increasing intracavity gain, improving stability, and increasing pulse gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

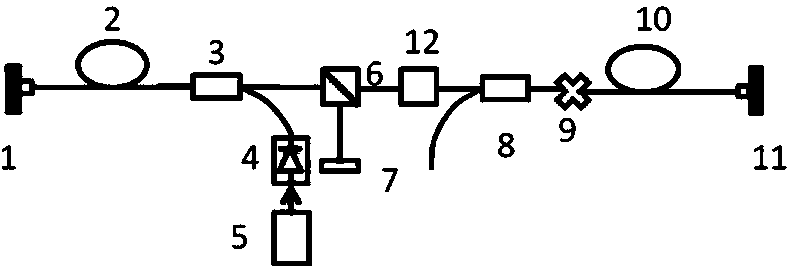

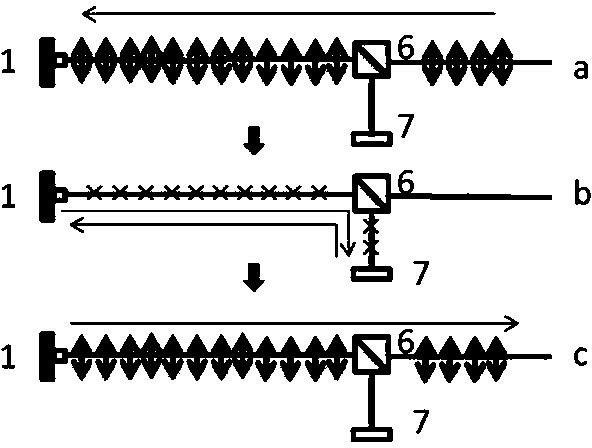

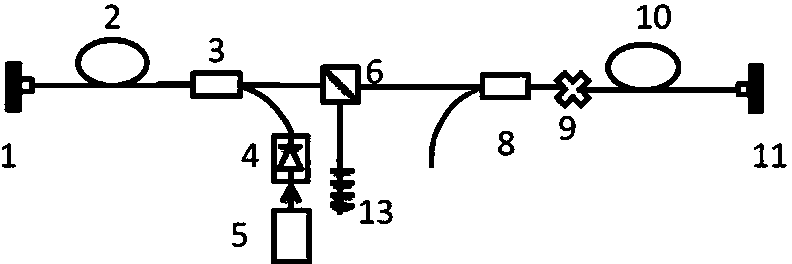

[0028] refer to image 3 , the present embodiment is pumped by 976nm semiconductor laser LD 5, 976nm high-power optical isolator 4, single-mode gain fiber 2 is highly doped gain medium, two Faraday polarization rotating total reflection mirrors 1, 11, polarization splitter Beamer 6 and fiber grating 13, wavelength division multiplexer 3, fiber laser coupler 8, and the angle between two polarization-maintaining fibers is 30 0The fusion splicing state 9 and the polarization maintaining single-mode fiber 10 constitute. The Faraday polarization rotator mirrors 1 and 11 are the cavity mirrors of the standing wave cavity. The two-cavity mirror enables the linear noise and disturbance caused by the entire fiber laser cavity to be compensated without external influence, so that the invention can work stably for a long time. The horizontally polarized pulsed light exits the polarization beam splitter 6 and enters the wavelength division multiplexer 3, and is amplified once in the gai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com