Ring cavity fiber laser system

A fiber laser and ring cavity technology, applied in the field of lasers, can solve the problems of laser pulse disturbance, loss of lock of fiber lasers, etc., and achieve the effect of self-stabilization and labor cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

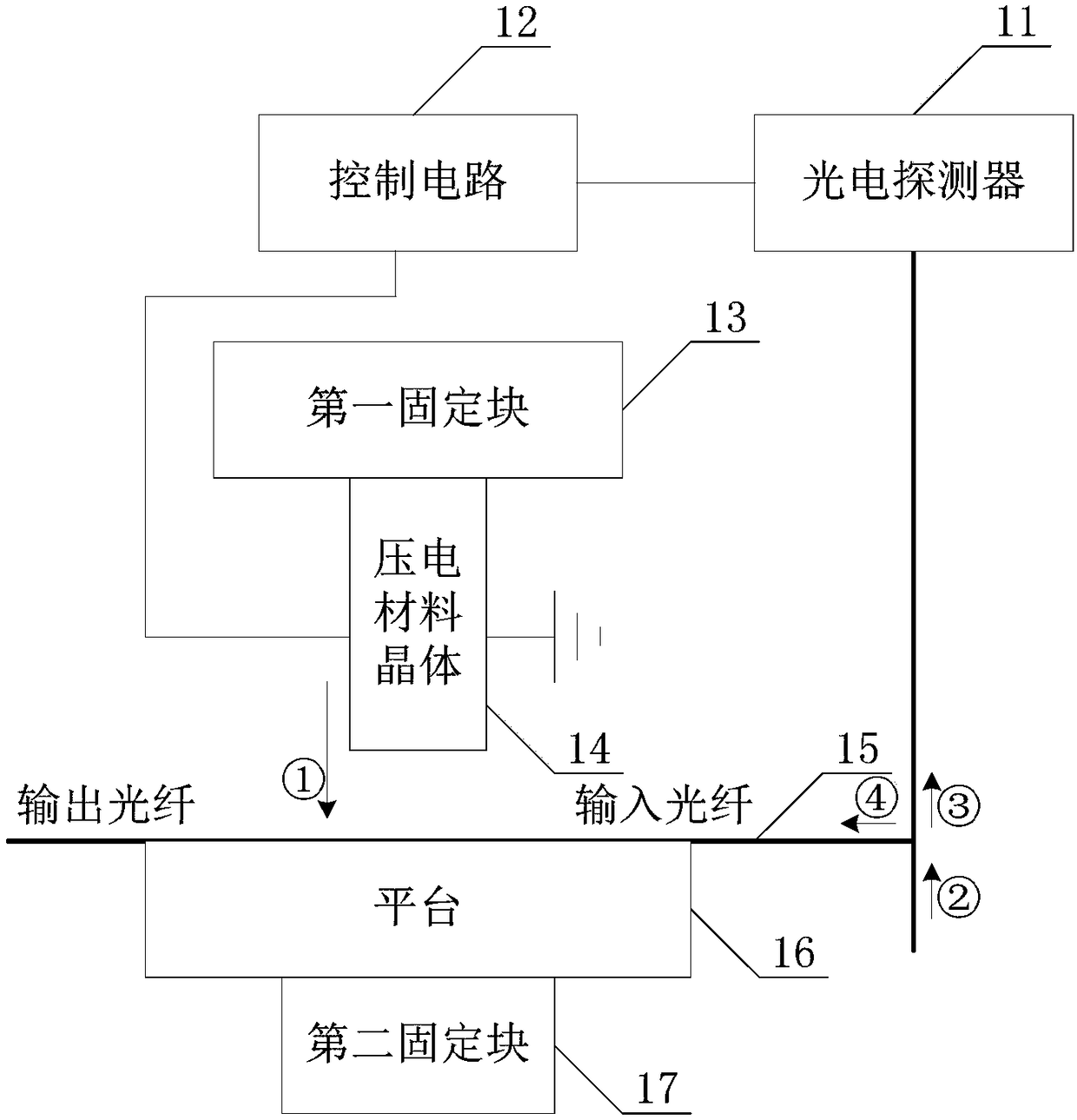

[0010] see figure 1 , figure 1 It is a structural schematic diagram of an embodiment of the optical fiber polarization control device of the present invention. Such as figure 1 As shown, the optical fiber polarization control device in the present invention is composed of two parts, namely the optical fiber polarization control device and the photodetector 11, wherein the optical fiber polarization control device includes a pressure component and a control circuit 12, and the pressure generation component includes a first fixed block 13 and piezoelectric material crystals 14 . The optical fiber 15 is arranged on the platform 16, and the platform 16 is fixed by the second fixing block 17, so that the position of the optical fiber 15 is fixed.

[0011] Wherein, the optical fiber polarization control device is coupled with the photodetector 11 . Specifically, the photodetector 11 transmits information to the control circuit 12 in a wireless / wired manner. Optionally, the phot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com