Medicine for treating ulcerative colitis and preparation method thereof

A technology for ulcerative colitis and drugs, which is applied in the direction of medical formulas, medical preparations containing active ingredients, drug delivery, etc., can solve the problems of side effects and high prices, and achieve antipyretic effect, convenient administration, and no side effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

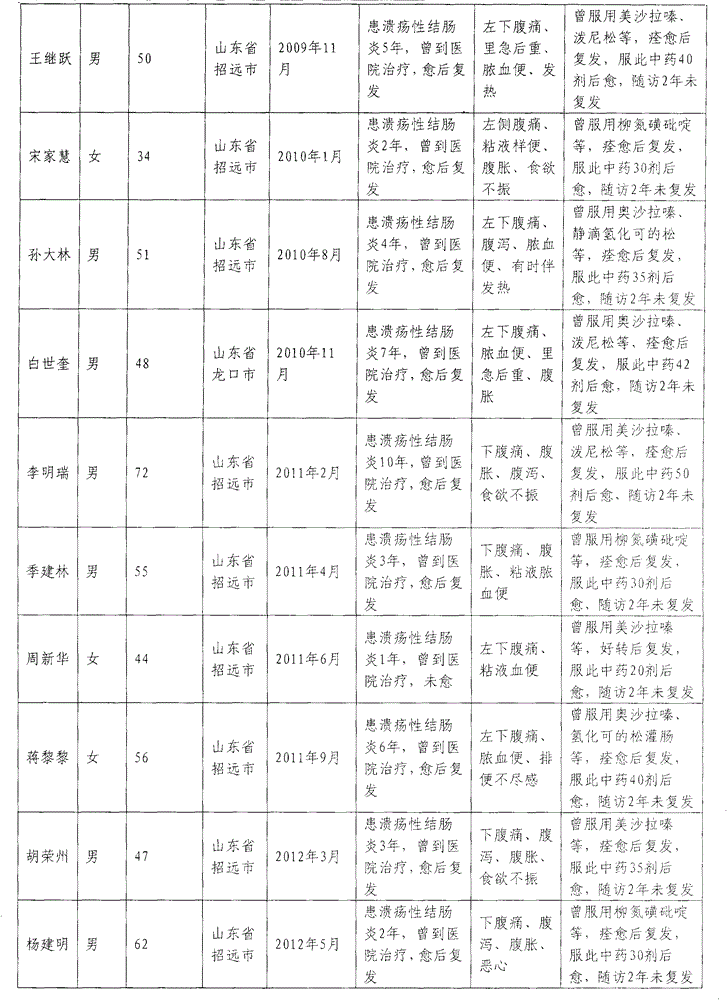

Examples

Embodiment 1

[0027] Example 1: Taking the manufacture of pills as an example, take 4g of Cortex Phellodendri, 4g of Coptidis Rhizoma, 10g of Astragalus, 10g of Atractylodes Rhizome, 10g of Sophorae Paeoniae Alba, 10g of Radix Paeoniae Alba, 10g of Radix Glycyrrhiza, 15g of Poria, 10g of Burnet elm, and 4g of woody incense; first mix the above raw materials OK, clean it up; then put the cleaned raw materials into the drying box for drying, then grind them into granules, and then use a 100-mesh sieve to sieve the ground raw materials, and filter out the small particles. For later use, the larger particles are ground and sieved to finally achieve the purpose of sieving; then 87 grams of honey is put into a pot and refined with low heat until it is condensed into a syrupy shape, and it is not burnt when stirred; finally, the Mix the refined honey with the above-mentioned medicinal powder and knead evenly, leave it for about half an hour, knead again, and make a honeyed pill of about 6 grams.

Embodiment 2

[0028] Example 2: Taking the manufacture of powdered granules as an example, get Phellodendron 8g, Coptidis 8g, Radix Astragali 20g, Atractylodes macrocephala 20g, Sophorae japonica 20g, Radix Paeoniae Alba 20g, Radix Glycyrrhizae 20g, Poria cocos 20g, Burnet elm 15g, Woody incense 10g; The raw materials are mixed and cleaned; then the cleaned raw materials are put into the drying box for drying, and then ground into granules, and then the ground raw materials are sieved with a 100-mesh sieve, and the small particles are filtered Take it out for later use, and then grind and sieve the larger particles, and finally achieve the purpose of sieving, and finally bag it in units of 6g.

Embodiment 3

[0029] Embodiment 3: Taking the manufacture of decoction as an example, get Cortex Phellodendri 10g, Coptidis Rhizoma 10g, Radix Astragali 25g, Atractylodes Rhizoma 25g, Sophorae japonica 25g, Radix Paeoniae Alba 25g, Radix Glycyrrhizae 25g, Poria cocos 20g, Burnet elm 17g, Woody Fragrance 10g; Mix it well and clean it; then put the cleaned raw materials into the decoction utensils (casserole, earthen pot or aluminum pot are all acceptable), then add clean water that meets the standard of drinking water, and add enough water to soak the medicine surface by 23cm It is advisable; soak the medicine for half an hour before decocting, so as to fully decoct the medicine juice; then, boil it with a strong fire and then switch to a slow fire decoction, and stop when the decoction is about 20 minutes (based on the decoction of 250-300ml per dose) , remove the dregs, take decoction Serve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com