A kind of supported nano catalyst for catalytic conversion of carbon dioxide and its preparation method and application

A nano-catalyst, carbon dioxide technology, applied in the preparation of metal/metal oxide/metal hydroxide catalyst, carbon monoxide, organic compounds, etc., can solve the problems of low methanol selectivity, low carbon dioxide conversion rate, etc., and achieve active specific surface area. High, small size, high dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh 0.5gCu(NO 3 ) 2 ·3H 2 O was dissolved in 10mL of deionized water to make it completely dissolved to obtain a copper nitrate solution with a concentration of 0.2mol / L; add 28% ammonia water dropwise to the copper nitrate aqueous solution to adjust the pH value of the solution to 10; add 1g of silica gel, 80 Heat and stir at ℃ until the pH value becomes 6; centrifuge, pour off the supernatant, wash the solid with deionized water three times, dry at 120°C for 8 hours; roast at 450°C for 3 hours; reduce with pure hydrogen at 300°C for 5 hours to obtain Supported nano-catalyst 1 for hydrogenation of carbon dioxide to synthesize methanol and carbon monoxide, its transmission electron microscope image is shown in figure 1 , the average particle size of nano-Cu particles is 2.1nm, the degree of dispersion is 54%, and the active specific surface area is 367.9m 2 g -1 , the graph of the change of carbon dioxide conversion rate with the reaction time is shown in figure...

Embodiment 2

[0027] Weigh 0.7gCu(NO 3 ) 2 ·3H 2 O was dissolved in 10mL of deionized water to make it completely dissolved to obtain a nitric acid solution with a concentration of 0.3mol / L; add 28% ammonia water to the copper nitrate aqueous solution drop by drop to adjust the pH of the solution to 11; add 1g of silica gel and heat at 90°C Heat and stir until the pH value becomes 5; centrifuge, pour off the supernatant, wash the solid with deionized water three times, dry at 100°C for 8 hours; roast at 600°C for 3 hours; reduce with pure hydrogen at 300°C for 5 hours, and obtain Supported nano-catalyst 2 for hydrogenation of carbon dioxide to synthesize methanol and carbon monoxide, the analysis spectrum of gas chromatography hydrogen flame ionization detector is shown in Figure 4 .

Embodiment 3

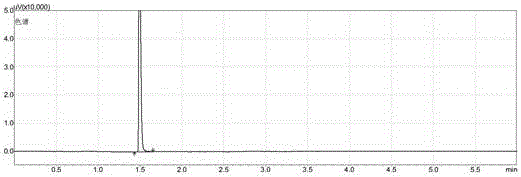

[0029] Weigh 0.4gCu(NO 3 ) 2 ·3H 2 O and 0.1gCo(NO 3 ) 2 ·6H 2 Dissolve O in 10mL deionized water to make it completely dissolved; add 28% ammonia water dropwise to the mixed solution to adjust the pH of the solution to 11; add 1g of silica gel, heat and stir at 80°C until the pH value becomes 6; centrifuge, Pour off the supernatant, wash the solid with deionized water three times, dry at 100°C for 8 hours; roast at 450°C for 6 hours, and reduce with pure hydrogen at 300°C for 5 hours to obtain a supported nanocatalyst for hydrogenation of carbon dioxide to synthesize methanol and carbon monoxide 3. The analysis spectrum of gas chromatography hydrogen flame ionization detector is shown in Figure 5 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com