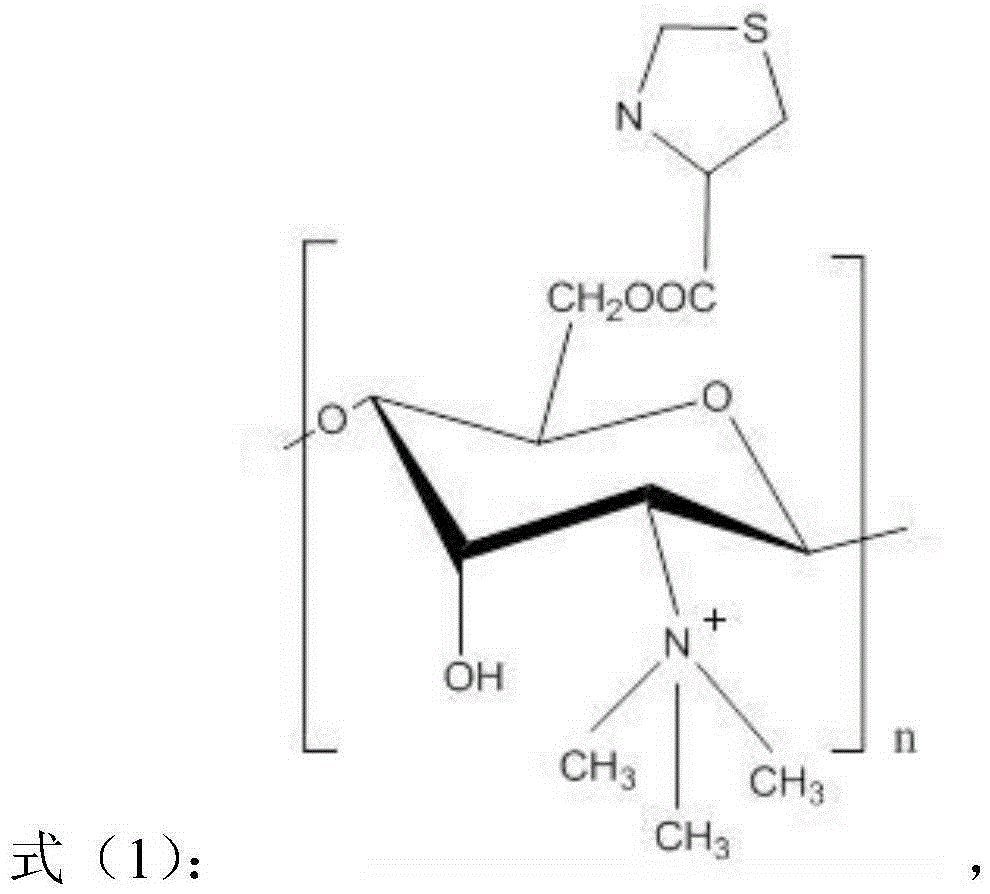

O-thiazolidine methyl ester-n-trimethyl chitosan quaternary ammonium salt and its preparation method and application

A technology of trimethyl chitosan and thiazolidine methyl ester is applied in the field of polymer compound materials, which can solve problems such as limited application, and achieve the effects of enhancing antibacterial activity and hydrophilicity, good antibacterial property, and expanding the scope of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

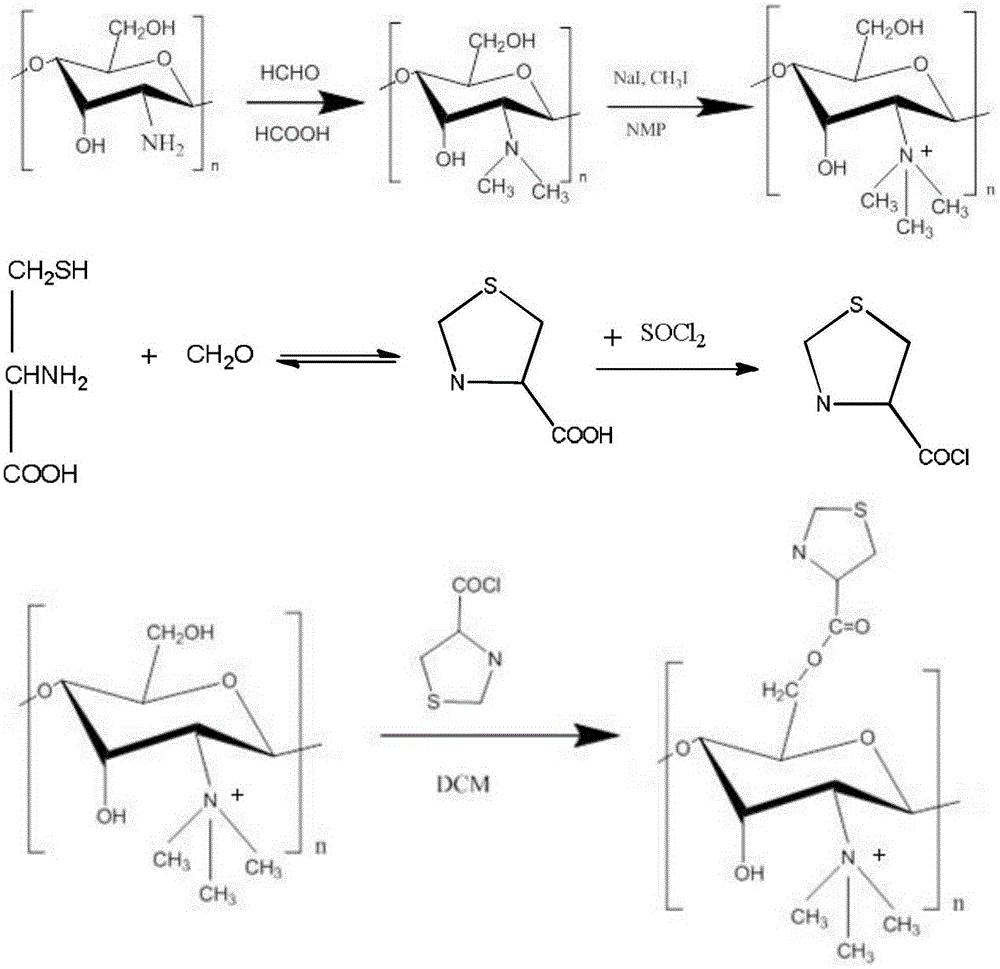

[0030] A kind of O-thiazolidine methyl ester-N-trimethyl chitosan quaternary ammonium salt, its preparation method is as follows:

[0031] (1) Dissolve 4g of chitosan in 200mL of deionized water and 15mL of formic acid, stir and heat up to 70°C, add 10mL of formaldehyde solution, mix well and transfer to a microwave normal pressure reactor, adjust the microwave power to 400W React at 30°C for 240 minutes; adjust the pH to alkaline with 15% NaOH solution, filter with suction, wash with water until neutral, add to 50mL N-methyl-2-pyrrolidone (NMP) after drying, add 20mL methyl iodide , react at 40° C. for 120 h; add twice the volume of V (ether) / V (ethanol) = 1:1 mixed solvent for precipitation, use deionized water to dialyze and freeze-dry to obtain N-trimethyl chitosan.

[0032] The substitution degree of N-trimethyl chitosan quaternary ammonium salt is 63% through photoelectron spectroscopy quantitative analysis (XPS) for C and N element analysis.

[0033] (2) Pipette 10 g o...

Embodiment 2

[0036] A kind of O-thiazolidine methyl ester-N-trimethyl chitosan quaternary ammonium salt, its preparation method is as follows:

[0037] (1) Dissolve 4g of chitosan in 200mL of deionized water and 15mL of formic acid, stir and heat up to 70°C, add 10mL of formaldehyde solution, mix well and transfer to a microwave normal pressure reactor, adjust the microwave power to 500W React at 40°C for 180min; adjust the pH to alkaline with 15% NaOH solution, filter with suction, wash with water until neutral, add to 50mL N-methyl-2-pyrrolidone after drying, add 40mL methyl iodide, 40°C React for 120 h; add two volumes of V (ether) / V (ethanol) = 1:1 mixed solvent for precipitation, use deionized water to dialyze and freeze-dry to obtain N-trimethyl chitosan.

[0038] The substitution degree of N-trimethyl chitosan quaternary ammonium salt is 69% through photoelectron spectroscopy quantitative analysis (XPS) for C and N element analysis.

Embodiment 3

[0042] A kind of O-thiazolidine methyl ester-N-trimethyl chitosan quaternary ammonium salt, its preparation method is as follows:

[0043] (1) Dissolve 4g of chitosan in 200mL of deionized water and 15mL of formic acid, stir and heat up to 70°C, add 10mL of formaldehyde solution, mix well and transfer to a microwave normal pressure reactor, adjust the microwave power to 600W React at a temperature of 50°C for 120 minutes; use 15% NaOH solution to adjust the pH to alkaline, filter with suction, wash with water until neutral, add to 50mL N-methyl-2-pyrrolidone after drying, add 60mL methyl iodide, 40°C React for 120 h; add two volumes of V (ether) / V (ethanol) = 1:1 mixed solvent for precipitation, use deionized water to dialyze and freeze-dry to obtain N-trimethyl chitosan.

[0044] The substitution degree of N-trimethyl chitosan quaternary ammonium salt is 73% through photoelectron spectroscopy quantitative analysis (XPS) for C and N element analysis.

[0045] (2) Pipette 10 g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com