A kind of genetically engineered bacteria producing hyaluronic acid and its application

A technology of genetically engineered bacteria and hyaluronic acid, applied in the field of genetically engineered bacteria producing hyaluronic acid, can solve problems such as unseen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

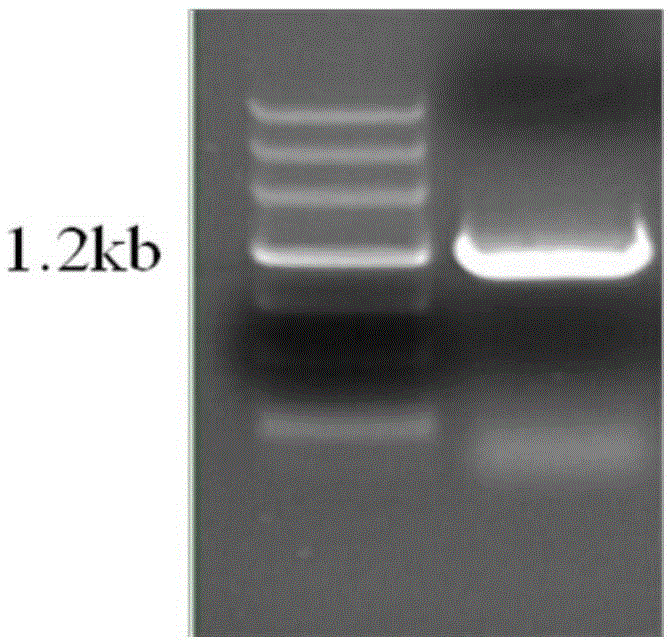

[0045] Construction of Corynebacterium glutamicum-Escherichia coli shuttle plasmid carrying hyaluronan synthase sHasA gene and CgHasB and CgHasC genes

[0046] Construction of plasmid pXMJ19-A: Based on the codon preference of Corynebacterium glutamicum and Escherichia coli, the gene sequence shasA of hyaluronan synthase sHasA was designed and chemically synthesized, as shown in SEQ ID No:1. The codon usage frequency of this gene and the protococcal Streptococcus equi hyaluronan synthase gene in Corynebacterium glutamicum is analyzed, and it is found that SEQIDNo:1 does not contain the highly rare codon of Corynebacterium glutamicum (the usage frequency is 0 -10%), the number of common rare codons is only 29, which is also greatly reduced compared to the 63 of the original gene. The codon usage frequency of SEQIDNo:1 in Escherichia coli was also analyzed, and it was found that SEQIDNo:1 is also suitable for expression in Escherichia coli, and does not contain highly rare codon...

Embodiment 2

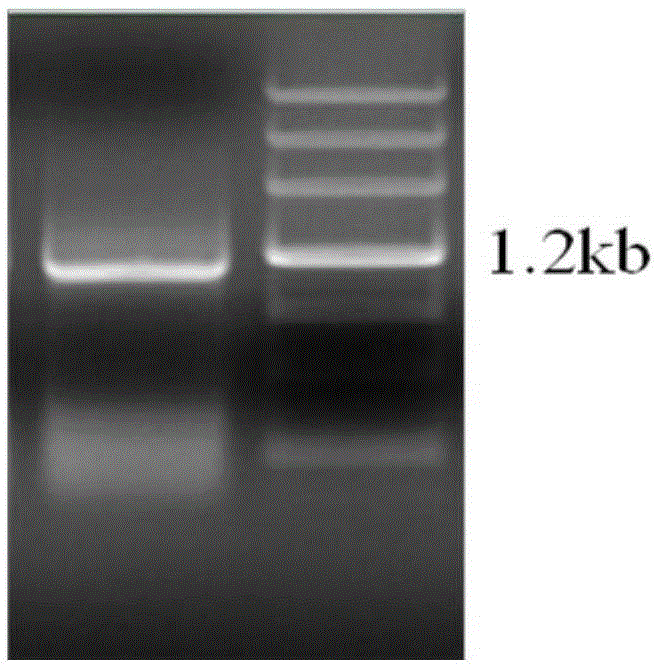

[0059] Construction of genetically engineered bacteria expressing hyaluronan synthase gene shasA and overexpressing CgHasB and CgHasB

[0060] The recombinant plasmid pXMJ19-A carrying hyaluronan synthase sHasA, the recombinant plasmid pXMJ19-AB overexpressing sHasA and CgHasB, and the recombinant plasmid pXMJ19-ABC overexpressing sHasA, CgHasB and CgHasC constructed in Example 1 were used as The competent cells of Corynebacterium glutamicum ATCC13032 are transformed by electroporation to obtain hyaluronic acid-producing genetically engineered bacteria C.gluA, C.gluAB and C.gluABC. Add 5 μL of recombinant plasmid and 100 μL of Corynebacterium glutamicum ATCC13032 competent cells to a 1.5mL centrifuge tube, mix well, add a 0.1cm electroporation cup, and ice-bath for 30min; adjust the voltage of the electroporator to 1.8kV, and put the electroporation cup into Press the electric shock button on the electroporation instrument; after the electric shock, add 1mL of SOC recovery med...

Embodiment 3

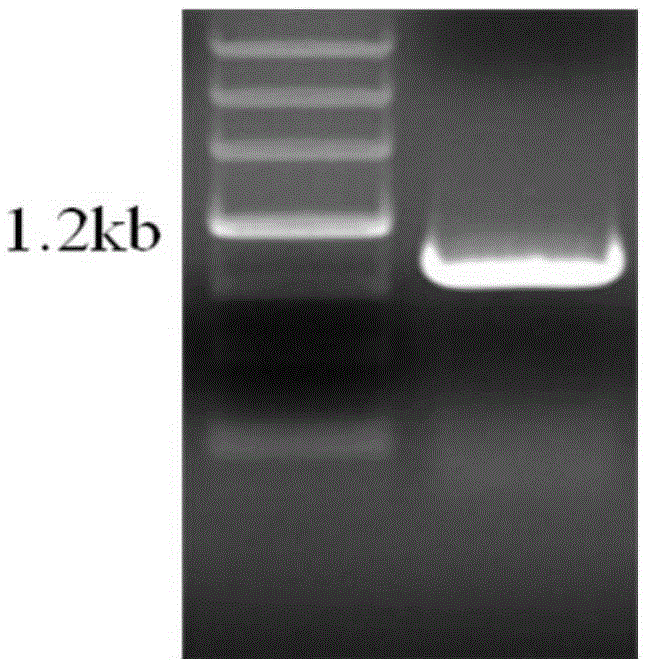

[0062] Production of Hyaluronic Acid Using Genetically Engineered Bacteria C.gluA, C.gluAB and C.gluABC

[0063] The Corynebacterium glutamicum C.gluP that is transformed into original plasmid pXMJ19 and the genetically engineered bacteria C.gluA, C.gluAB and C.gluABC that embodiment 2 gains are inoculated in LB liquid culture medium (containing 5 μ g / mL chloramphenicol) cultured at 37°C and 200rpm for 16 hours, inserted into LB liquid medium with a glucose concentration of 40g / L at a ratio of 5%, cultivated at 37°C and 200rpm for 3h, added IPTG (final concentration 1mM), and continued to cultivate until After 24 hours, centrifuge at 8000 rpm at room temperature to obtain a hyaluronic acid-containing fermentation broth. Take 1 mL of the obtained fermentation broth, add 1 mL of 0.1% w / v SDS solution and mix well, incubate at room temperature for 20 minutes; centrifuge at 12000 rpm for 10 minutes, transfer the supernatant to a new 10 mL EP tube, add 2 times the volume of ice eth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com