Production method of vermicular graphite cast iron

A technology for vermicular graphite cast iron and pig iron, which is applied in the field of producing vermicular graphite iron, can solve the problems of narrow interval, inability to overcome, and the vermicular rate cannot be well controlled stably, and achieves compact process, excellent high temperature performance and high process stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

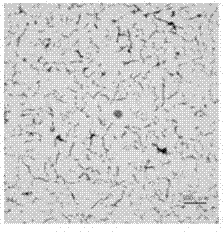

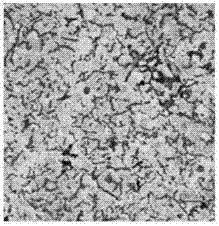

Image

Examples

Embodiment Construction

[0034] A method for producing compacted graphite cast iron, characterized in that: the method comprises the steps of:

[0035] a. Feeding: The feeding sequence is scrap steel-mechanical iron-pig iron to ensure a compact process and no phenomenon such as fluffing or over-burning;

[0036] b. Ferro-titanium is added to the furnace along with the first batch of charge, and the weight content is 0.1-0.3%;

[0037] c. Melting: melting process temperature <1380°C; sampling temperature is 1460-1480°C, overheating temperature is 1500-1510°C;

[0038] d. Embedding bag: Add vermicular agent to one side of the vermicular bag, pound it tightly, cover the inoculant, and then cover 1% to 2% of the broken steel pieces to meet the standard of covering the inoculant tightly. Put 0.5-0.8% copper at the input end;

[0039] e. Rapid one-time tapping, the tapping temperature is 1470-1490°C, no inoculation tank is used, and the molten iron is flushed against the side where no vermative agent is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com