Two-dimensional semiconductor alloy, preparation method and application thereof

A two-dimensional semiconductor and alloy technology, applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problem that the band gap cannot be continuously adjusted, and the large-area single-layer two-dimensional semiconductor nano-film cannot be continuous Growth and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] A method for preparing a two-dimensional semiconductor alloy using a chemical vapor deposition device. The chemical vapor deposition device is a device known in the art. The chemical vapor deposition device used in this embodiment includes a heating tube furnace and a quartz tube, wherein the quartz tube The length is 1.4m, the diameter is 1 inch, and there are vacuum valves at both ends of the quartz tube, which are used to evacuate the inside of the quartz tube and send protective gas; Heating and heat preservation, the heating furnace is provided with two independent thermocouples in the quartz tube for heating corresponding positions in the quartz tube;

[0077] The method comprises the steps of:

[0078] (1) Take commercially purchased silicon wafers (high P-silicon wafers purchased from Hefei Kejing Technology Co., Ltd., resistance value 0.02-0.6Ω, 0.5mm×4 inches), cut into small pieces of 6×8mm, after acetone, ethanol , Ultrapure water ultrasonic treatment 3 tim...

Embodiment 2

[0085] A method for preparing a two-dimensional semiconductor alloy using a chemical vapor deposition device, the chemical vapor deposition device is the same as in Example 1, and the difference between the method and Example 1 is:

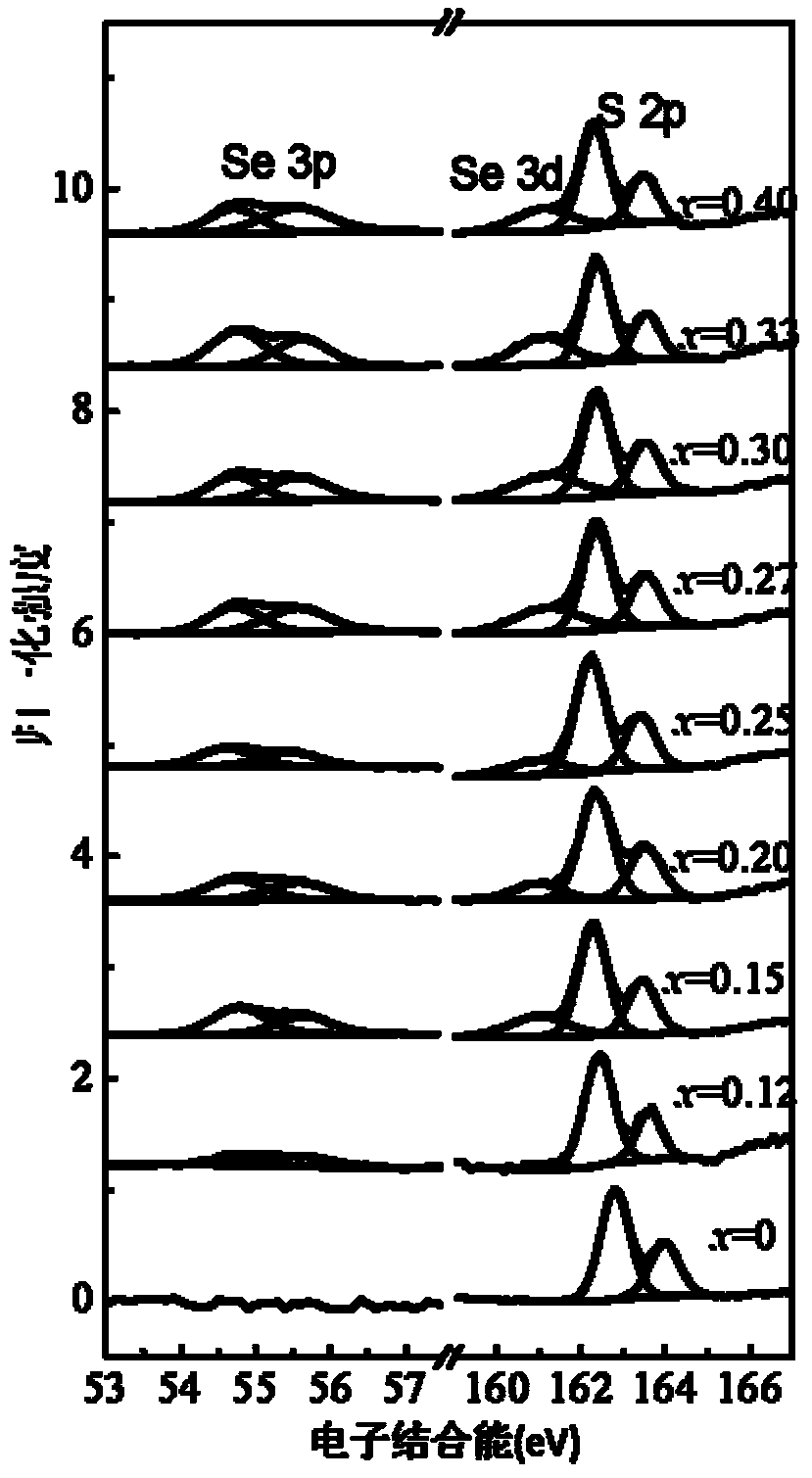

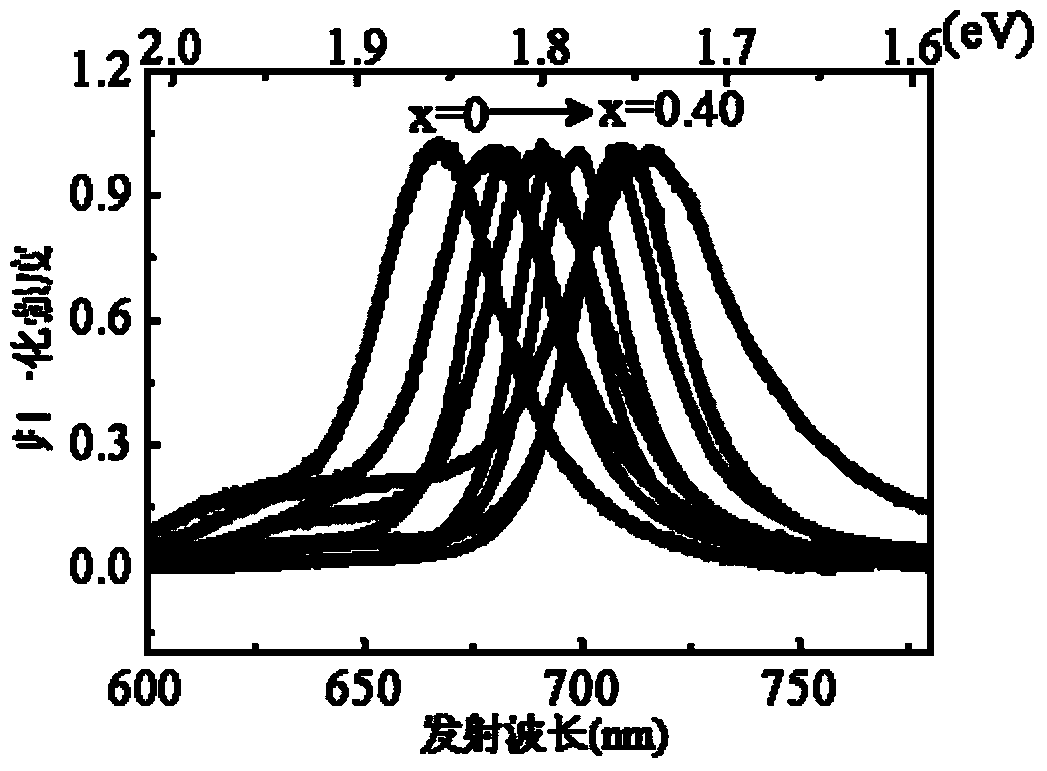

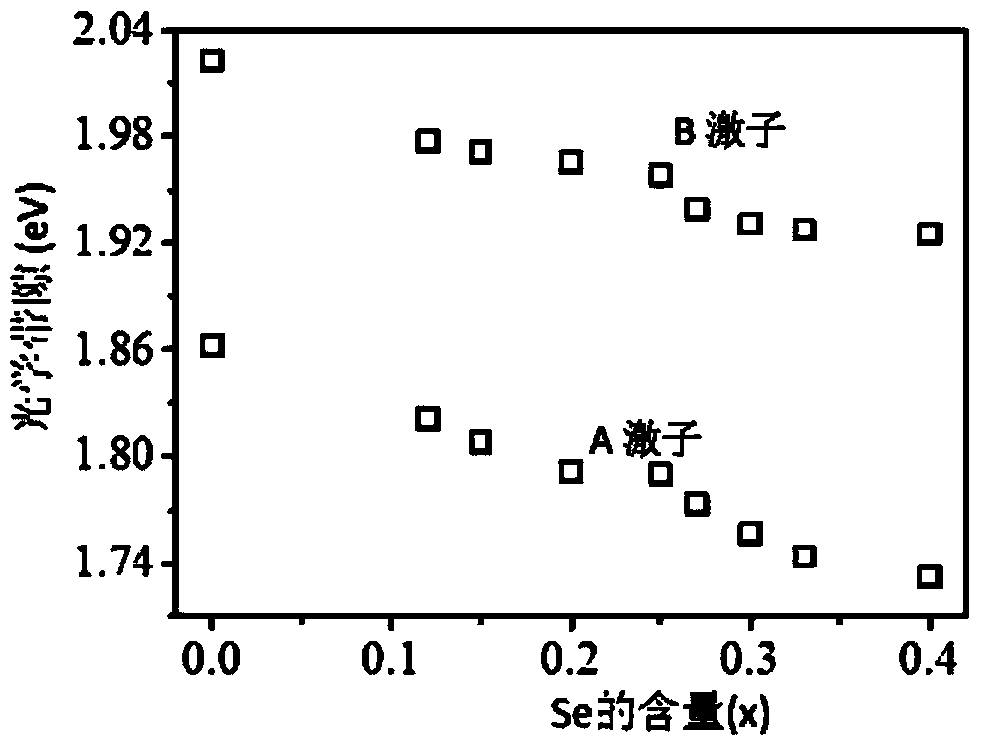

[0086] The heating volatilization temperature of molybdenum sulfide and molybdenum selenide in step (4), because the volatilization temperature of molybdenum sulfide and molybdenum selenide is different, the volatilization amount of the two is different, and the obtained two-dimensional semiconductor alloy MoS 2(1-x) Se 2x The growth results of are also different, specifically as described in Table 1;

[0087] Table 1 MoS obtained at different volatilization temperatures 2(1-x) Se 2x growth results

[0088] serial number T 硒化钼 (℃) T 硫化钼 (℃) ΔT (°C) x value Optical bandgap (eV) Emission wavelength (nm) 1 —— 940 —— 0 1.862±0.004 665~670nm 2 940 940 0 0.12 1.820±0.007 678~683 3 945 940 5 0.15 1.808...

Embodiment 3

[0098] A method for preparing a two-dimensional semiconductor alloy using a chemical vapor deposition device, the chemical vapor deposition device is the same as in Example 1, and the difference between the method and Example 1 is:

[0099] The silicon substrate in step (1) directly adopts commercially purchased silicon wafers (high P-silicon wafers purchased from Hefei Kejing Technology Co., Ltd., resistance value 0.02-0.6Ω, 0.5mm×4 inches), and cuts to obtain 6×8mm The flakes were obtained after ultrasonic treatment of acetone, ethanol, and ultrapure water three times each;

[0100] Step (3) The step of removing the oxidizing gas is: evacuate the inside of the quartz tube to 1-2Pa, pass in argon gas, and then evacuate to 1-2Pa again, repeat 3 times;

[0101] The flow rate of the protective gas introduced in step (4) is 10 sccm; the heating temperatures of molybdenum sulfide and molybdenum selenide in the quartz tube are 940°C and 990°C respectively; the mass ratio of molybde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com