Heat pipe based on carbon nanotube wick and preparation method thereof

A technology of carbon nanotubes and carbon nanotube arrays, which is applied in the field of heat pipes based on carbon nanotube liquid-absorbing cores and its preparation, can solve the problems of no essential improvement in the working efficiency of heat pipes, failure to reach the overall size of heat pipes, and cumbersome manufacturing processes. To achieve the effect of simplifying the molding process, avoiding technical difficulty and cost, and reducing thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the features and effects of the present invention.

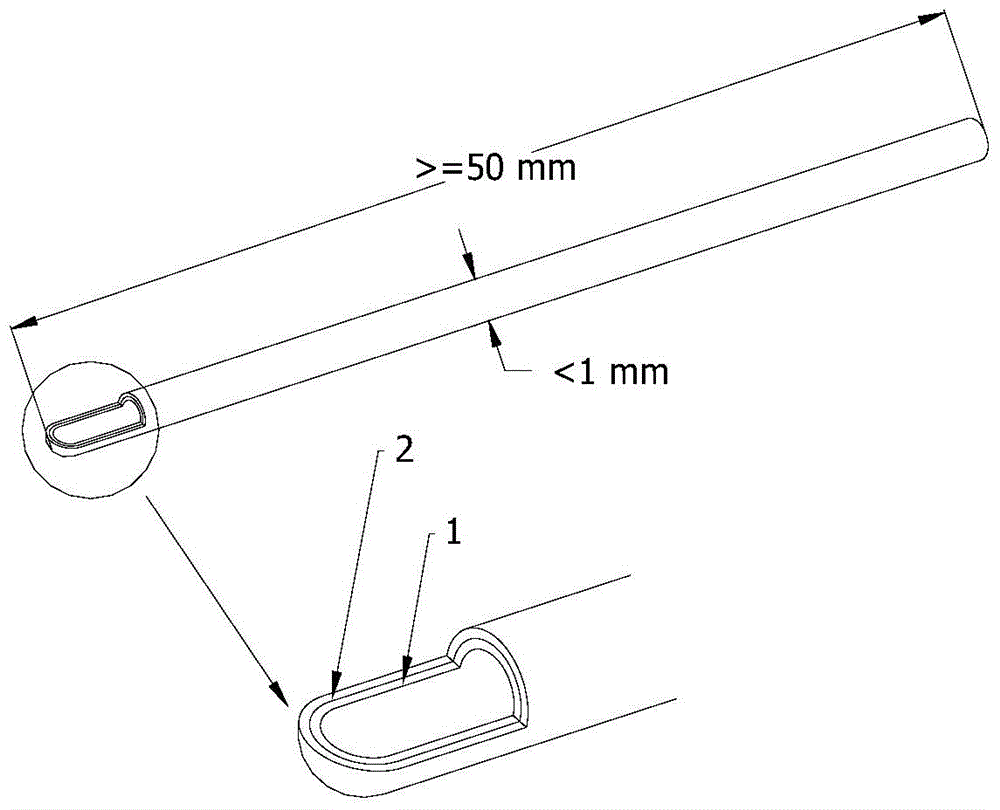

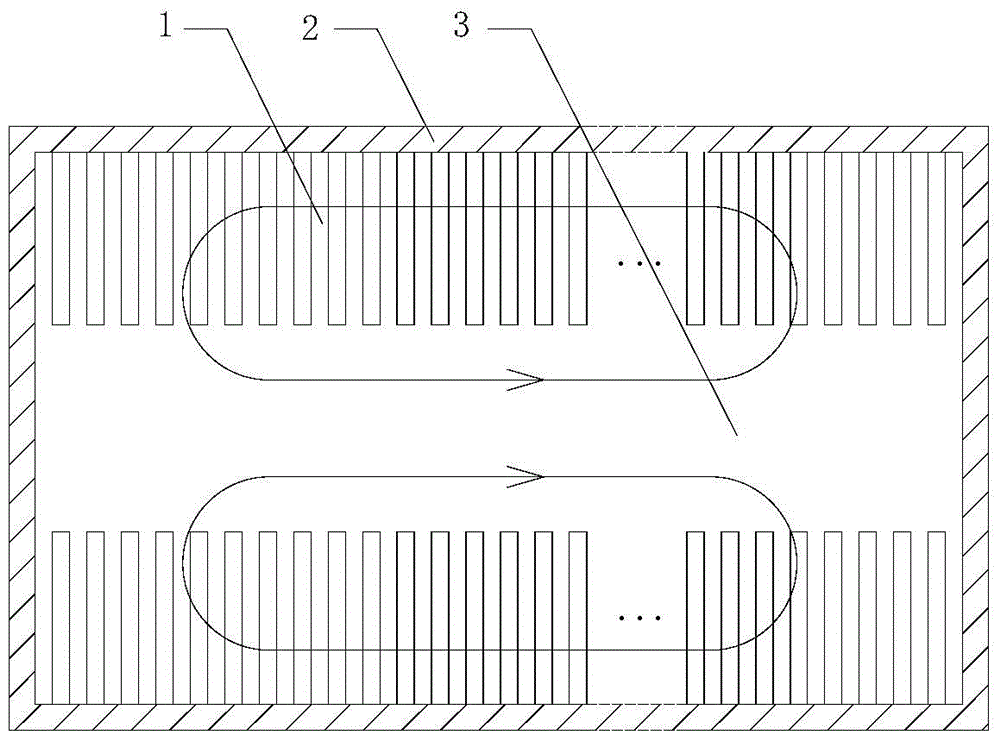

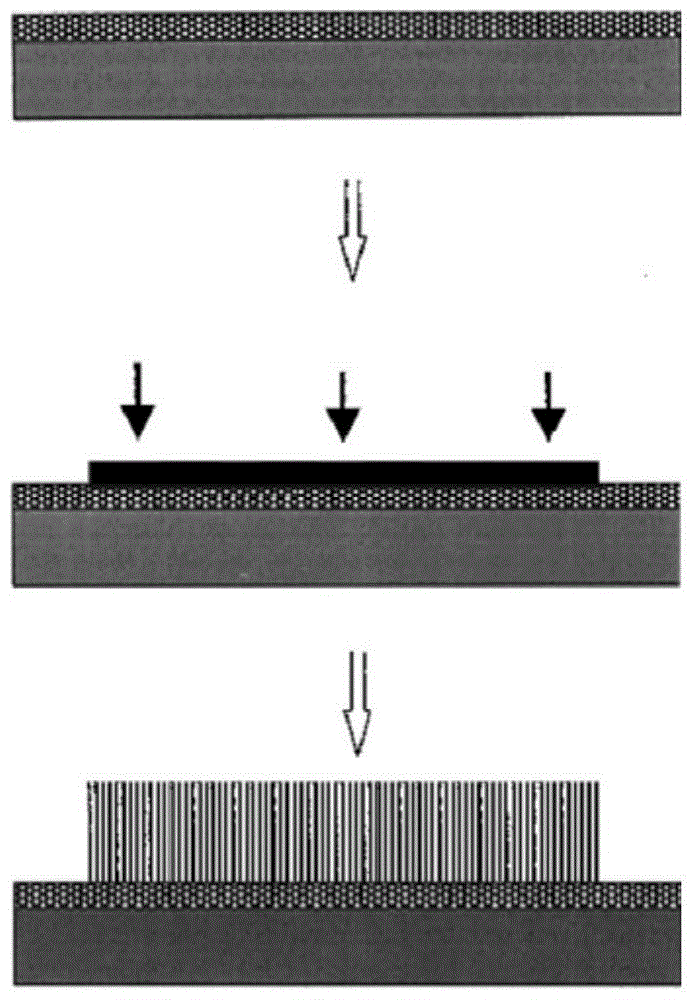

[0032] figure 1 It is a three-dimensional structural schematic diagram of a preferred embodiment of the present invention. When one end of the heat pipe is heated, the liquid evaporates, flows along the middle cavity to the condensation section, releases the heat and condenses into a liquid, and finally the liquid flows back to the evaporation section under the action of the liquid-absorbing core to complete the cycle. The overall working principle of the heat pipe with carbon nanotube liquid-absorbing core structure is basically the same as that of conventional heat pipes with traditional liquid-absorbent core structure, such as figure 2 shown. However, due to the adoption of the liquid-absorbing core structure, its overall radial dimension i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| verticality | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com