A transfer transistor structure

A transfer transistor and reset tube technology, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, circuits, etc., can solve the problems of weakening the output signal at the signal output end, high power consumption, and increasing the difficulty of turning on, so as to reduce the loss of voltage drop, Improve the output intensity, power consumption has no effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

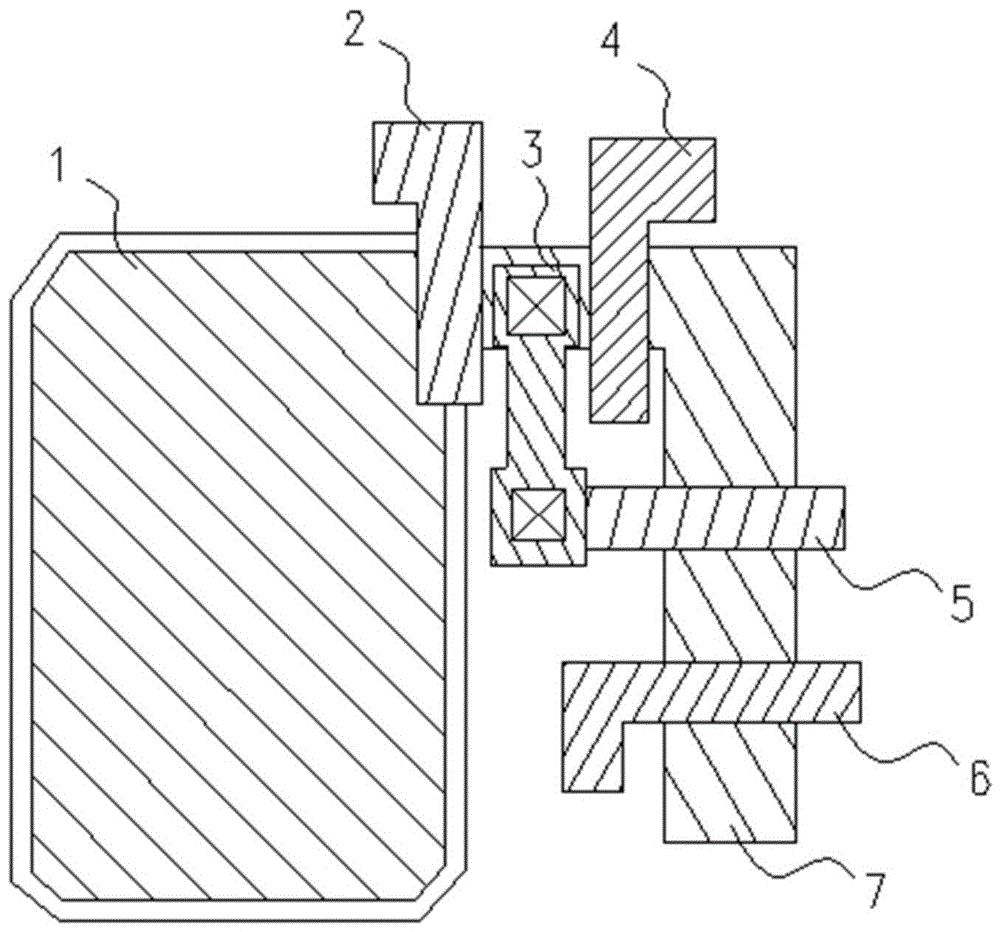

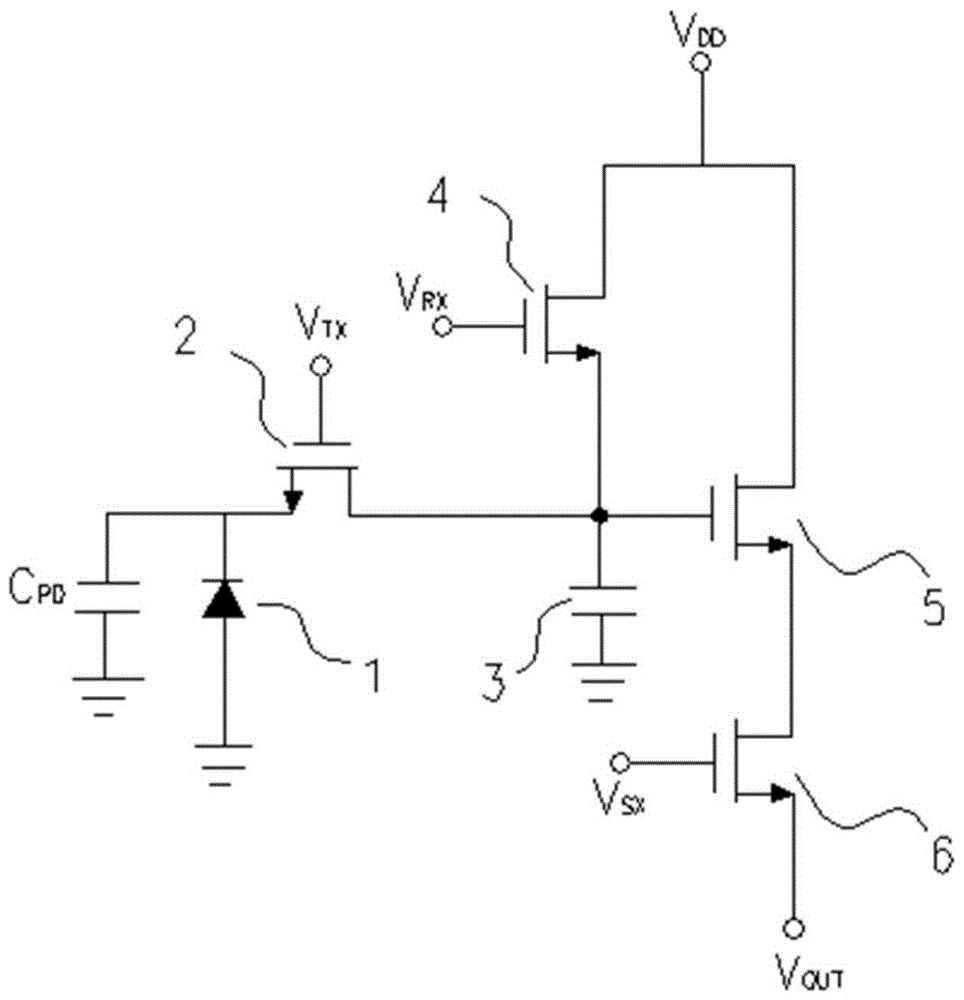

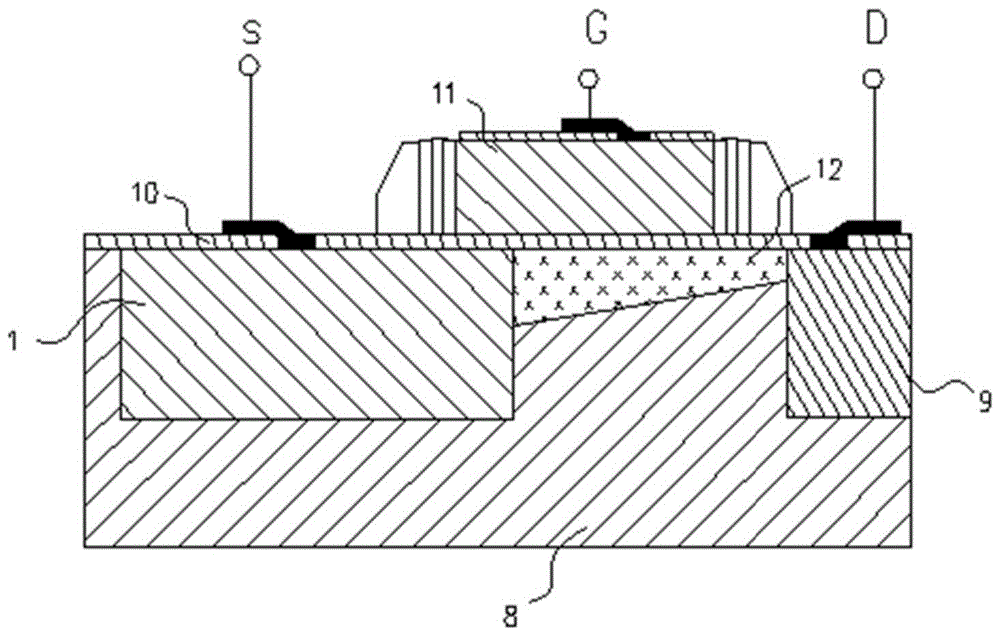

[0034] Such as Figure 4 As shown, a transmission transistor structure for enhancing the output signal of a CMOS image sensor includes a photodiode 1, a P-type silicon base 8, a drain terminal 9, an insulating layer 10, and a polysilicon gate 11; the photodiode 1 serves as the source terminal of the transmission transistor 2, The source terminal and the drain terminal 9 form an NPN junction on the P-type silicon base 8. The photodiode 1, the P-type silicon base 8, the drain terminal 9, the insulating layer 10 and the polysilicon gate 11 are used in the CMOS image sensor. The CMOS image sensor also includes Amplifier 5, reset tube 4, capacitor 3, strobe 6, V TX Power supply, V RX Power supply, V DD Power and V SX The drain terminal 9 of the transfer transistor 2 is connected to the gate of the amplifier 5 and the source of the reset tube 4, and the crystalline silicon gate of the transfer transistor 2 is connected to the power source V TX Connected; the photodiode 1 of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com