Treatment solution for nucleated pearl culture

A technology for treating liquid and pearls, applied in application, fish farming, climate change adaptation, etc., can solve the problems of poor quality, low survival rate, dull luster of nucleated pearls, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment relates to a treatment solution for nucleated pearl culture,

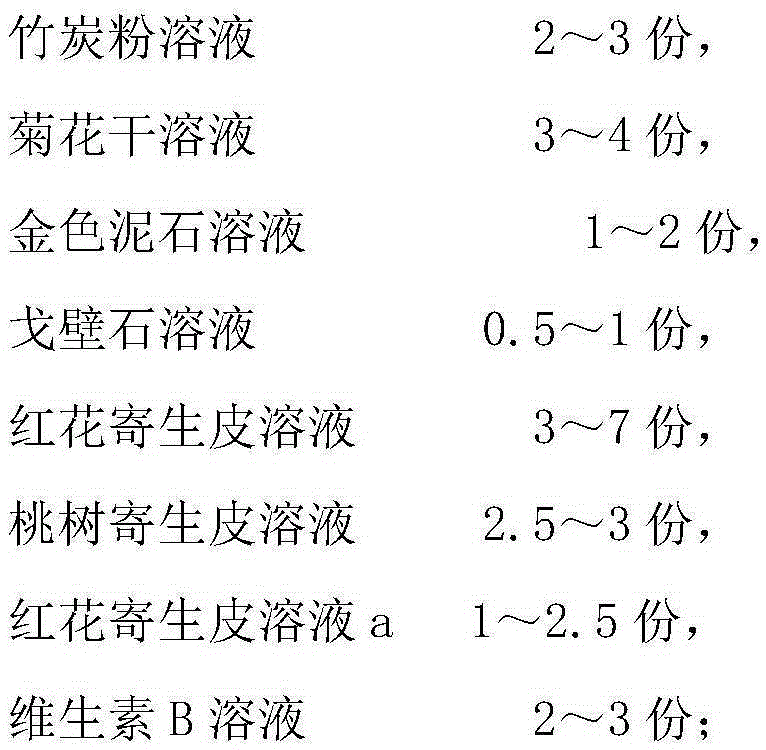

[0035] The first treatment liquid involved in this embodiment includes the following components in parts by weight:

[0036]

[0037]

[0038]The bamboo charcoal powder solution adopted in the present embodiment refers to the bamboo charcoal mixed with pure water in a mass ratio of 1:3 after being pulverized, and filtered to obtain the solution. 1:2 mixing, filtering, and the obtained solution. The golden mudstone solution refers to the pulverized golden mudstone mixed with pure water at a mass ratio of 1:1, and filtered to obtain the solution. The Gobi stone solution refers to the pulverized Gobi stone mixed with Purified water is mixed at a mass ratio of 1:3, filtered, and the solution obtained, the safflower parasitic bark solution refers to the safflower parasitic bark pulverized and mixed with pure water at a mass ratio of 1:5, the obtained solution, peach tree parasitic bark The ...

Embodiment 2

[0053] This embodiment relates to a treatment solution for nucleated pearl culture,

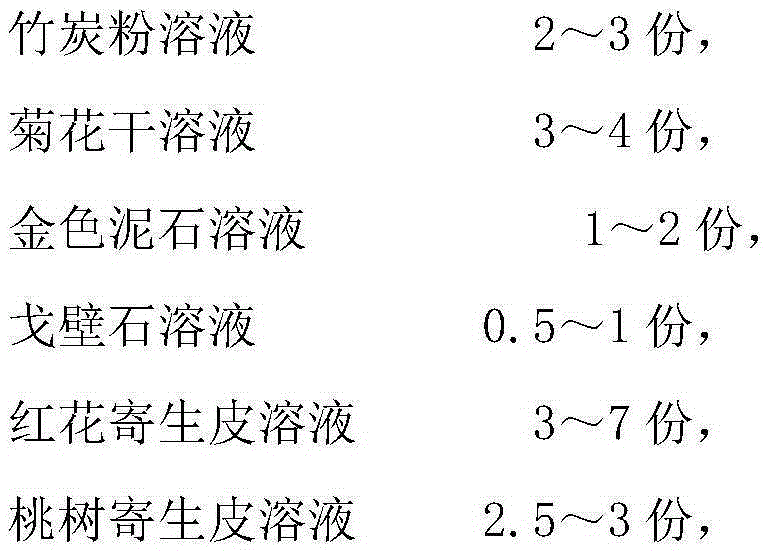

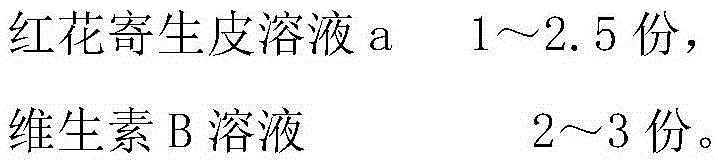

[0054] The first treatment liquid involved in this embodiment includes the following components in parts by weight:

[0055]

[0056]

[0057] The bamboo charcoal powder solution adopted in the present embodiment refers to the bamboo charcoal mixed with pure water in a mass ratio of 1:3 after being pulverized, and filtered to obtain the solution. 1:2 mixing, filtering, and the obtained solution. The golden mudstone solution refers to the pulverized golden mudstone mixed with pure water at a mass ratio of 1:1, and filtered to obtain the solution. The Gobi stone solution refers to the pulverized Gobi stone mixed with Purified water is mixed at a mass ratio of 1:3, filtered, and the solution obtained, the safflower parasitic bark solution refers to the safflower parasitic bark pulverized and mixed with pure water at a mass ratio of 1:5, the obtained solution, peach tree parasitic bark The...

Embodiment 3

[0065] This embodiment relates to a treatment solution for nucleated pearl culture,

[0066] The first treatment liquid involved in this embodiment includes the following components in parts by weight:

[0067]

[0068]

[0069] The bamboo charcoal powder solution adopted in the present embodiment refers to the bamboo charcoal mixed with pure water in a mass ratio of 1:3 after being pulverized, and filtered to obtain the solution. 1:2 mixing, filtering, and the obtained solution. The golden mudstone solution refers to the pulverized golden mudstone mixed with pure water at a mass ratio of 1:1, and filtered to obtain the solution. The Gobi stone solution refers to the pulverized Gobi stone mixed with Purified water is mixed at a mass ratio of 1:3, filtered, and the solution obtained, the safflower parasitic bark solution refers to the safflower parasitic bark pulverized and mixed with pure water at a mass ratio of 1:5, the obtained solution, peach tree parasitic bark The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com