Metal rubber blank weaving equipment and special cover mechanism

A metal rubber and cover plate technology, applied in applications, household appliances, other household appliances, etc., can solve the problems of poor hook strength, high rejection rate, delamination and cracking, etc. rate reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

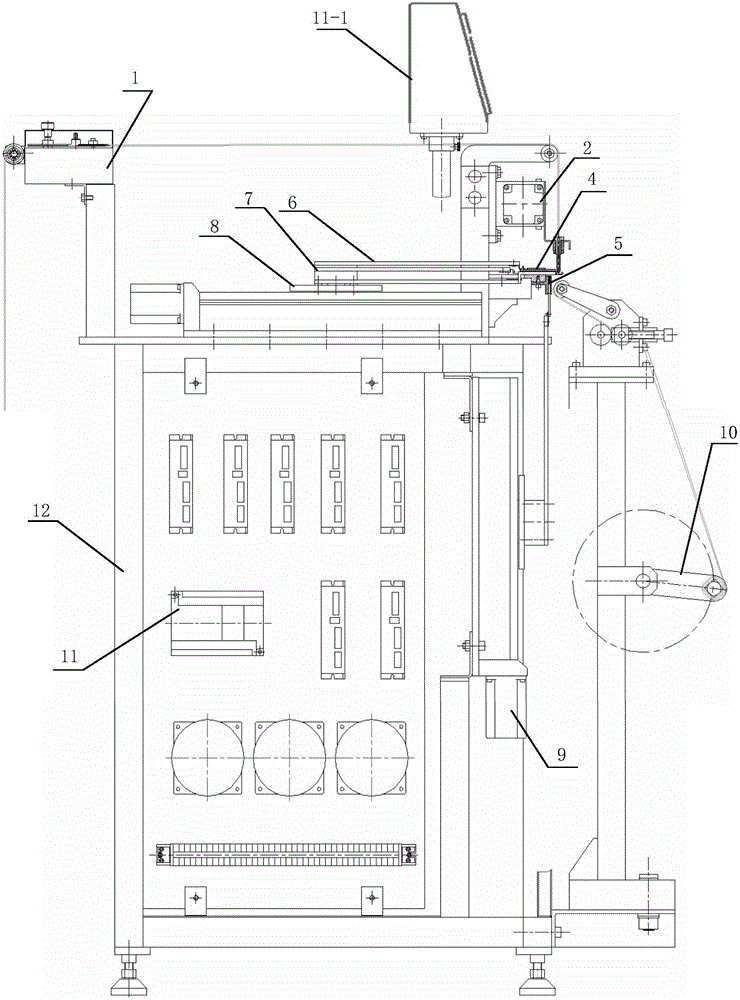

[0057] like Figure 1~Figure 3 As shown, the present invention includes a constant pitch stretching mechanism 1, a wiring mechanism 2, an auxiliary hook 3 (not shown), a horizontal chute plate 4, a vertical chute plate 5, a cover plate mechanism 6, a hook mechanism 7, and a horizontal auxiliary mechanism 8. Vertical auxiliary mechanism 9 , winding mechanism 10 , control system 11 and frame 12 .

[0058] like Figure 4~Figure 6 As shown, the constant pitch stretching mechanism 1 includes: a wire wheel 1-1, a damper 1-2, a damping wheel 1-3, a damping pressing wheel 1-4, a pressing device 1-5, and an active wire worm wheel 1 -6. The driven wire pay-off wheel 1-7 and the stretching motor 1-8.

[0059] The dense-turn metal wire helix is fed into the constant-pitch stretching mechanism 1 through the wire wheel 1-1. Under the control of the control system 11, it cooperates with the wiring mechanism 2 to realize the constant-pitch stretching of the dense-turn metal wire helix.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com