Electromagnetic riveting equipment adopting reciprocating type electromagnetic launching technology

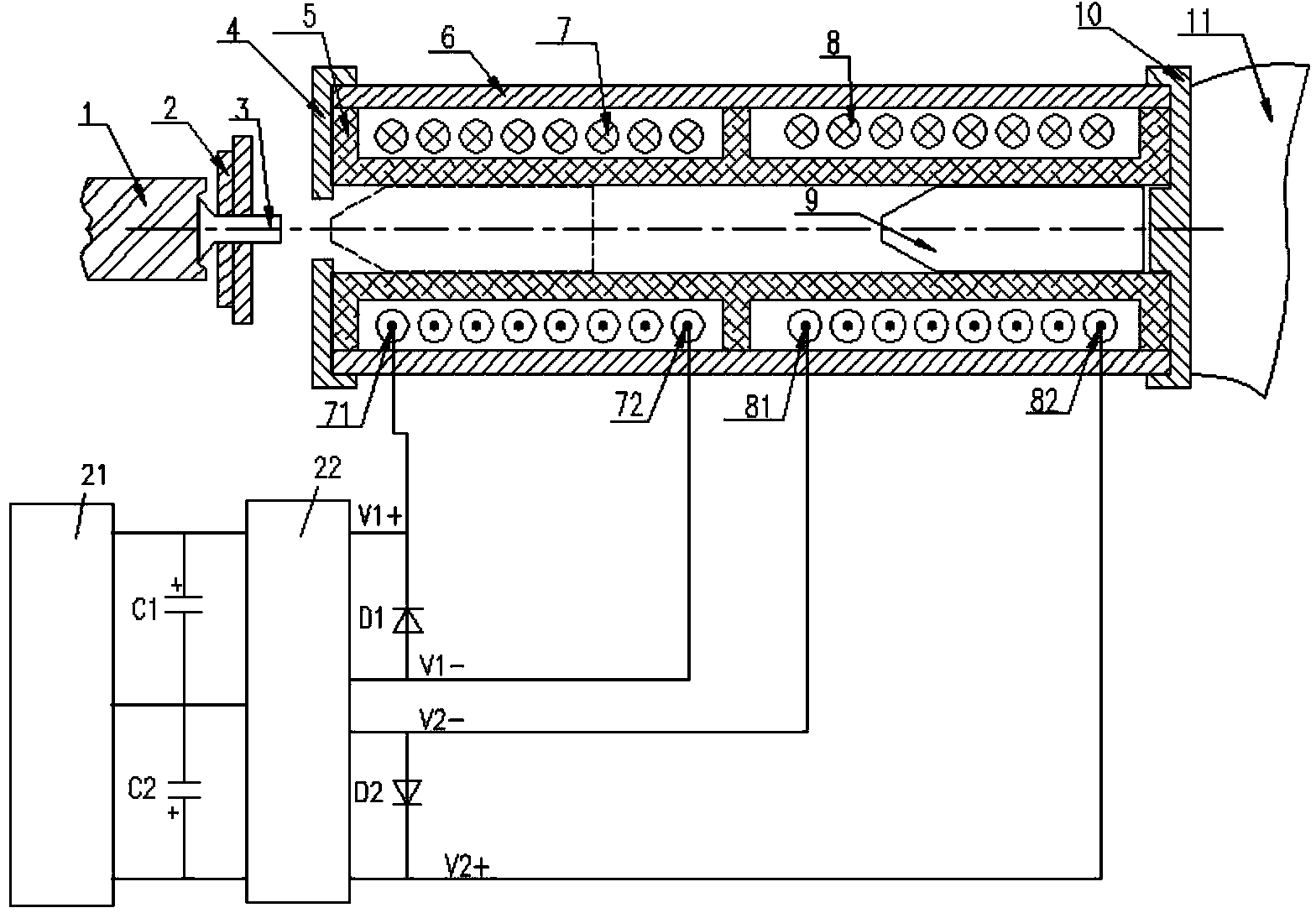

An electromagnetic riveting and reciprocating technology, applied in the field of mechanical connection, can solve the problems of heat generation, large size and weight of electromagnetic riveting equipment, and low energy utilization rate, and achieve the effects of small heat generation, improved energy utilization rate, and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] In this embodiment, a riveting gun was designed and manufactured according to the schematic diagram of the riveting gun, and a power supply was manufactured according to the schematic diagram of the power supply, and a riveting test was carried out with a top iron. The riveting system power supply includes a group of pulse capacitors with a rated voltage of 450 volts and a rated capacitance of 4700 microfarads connected in parallel to form a main coil discharge capacitor bank, and the auxiliary coil capacitor bank uses several capacitors with a rated voltage of 450 volts and a rated capacity of 2200 microfarads; The two discharge circuits use high-power semiconductor switches to control the discharge of the discharge circuit; the two charging circuits use a resonant soft switch to control the charge.

[0022] In the implementation, first charge the auxiliary coil capacitor to the set voltage, then discharge to pull the mover back to the initial position; then charge the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com