Processing method of human body implant titanium alloy arc-shaped plate

A processing method and titanium alloy technology, which is applied in the field of processing titanium alloy arc-shaped plates for human implants, can solve the problems that pure titanium arc-shaped plates are not suitable for processing titanium alloy arc-shaped plates, and improve the strength and processing efficiency. High performance and excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

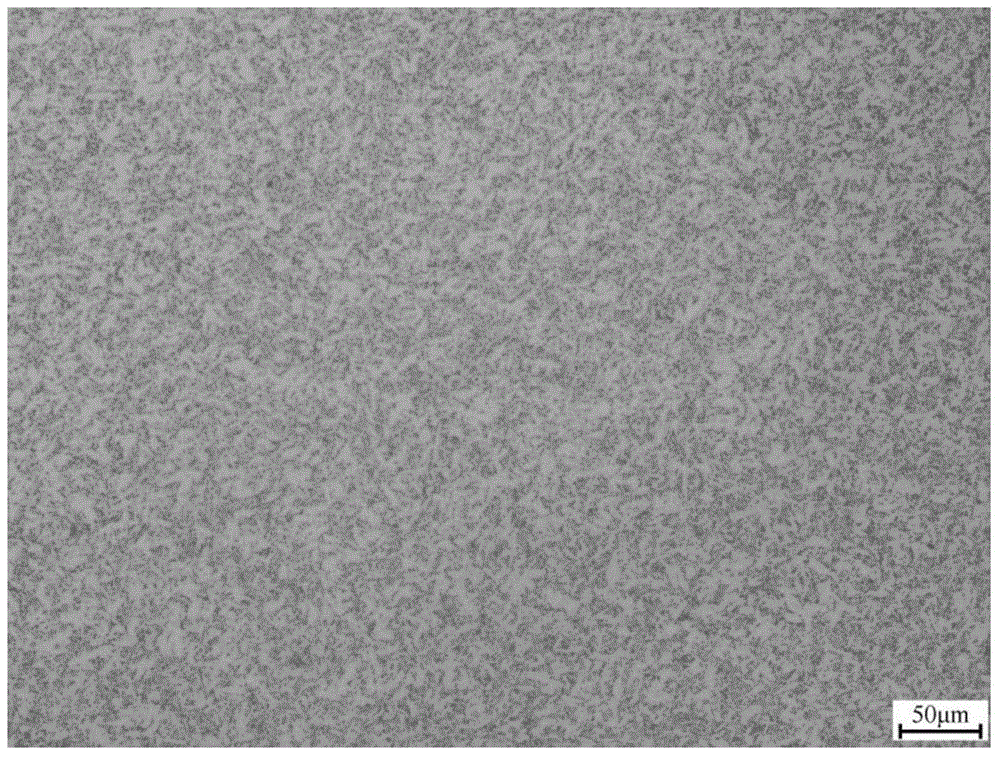

Embodiment 1

[0044] preparation TC4 titanium alloy curved plate;

[0045] Step 1, raw material preparation

[0046] According to the GB / T13810-2007 standard, select TC4 titanium alloy rods with Ф12mm, tensile strength ≥ 860MPa, elongation ≥ 10%, roughness 3.2μm, and the surface of the billet has no visible cracks, grinding lines, folding and other defects. The pit should transition smoothly to obtain TC4 titanium alloy blank;

[0047] Step 2, Rolling

[0048] The TC4 titanium alloy billet obtained in step 1 is first rolled to Ф10mm by the cold square process, and the pass processing rate is 3%; then it is heated by electric contact, and the infrared temperature control system is adopted. The heating temperature is 850 ° C, and the power is turned off when the temperature reaches ;A two-roll rolling mill is used to quickly flat-roll to a thickness of 5.0mm-5.5mm×width 15mm-16mm, and the processing rate of the flat-rolling pass is 10%; The processing rate of rolling 1 is 15%; followed b...

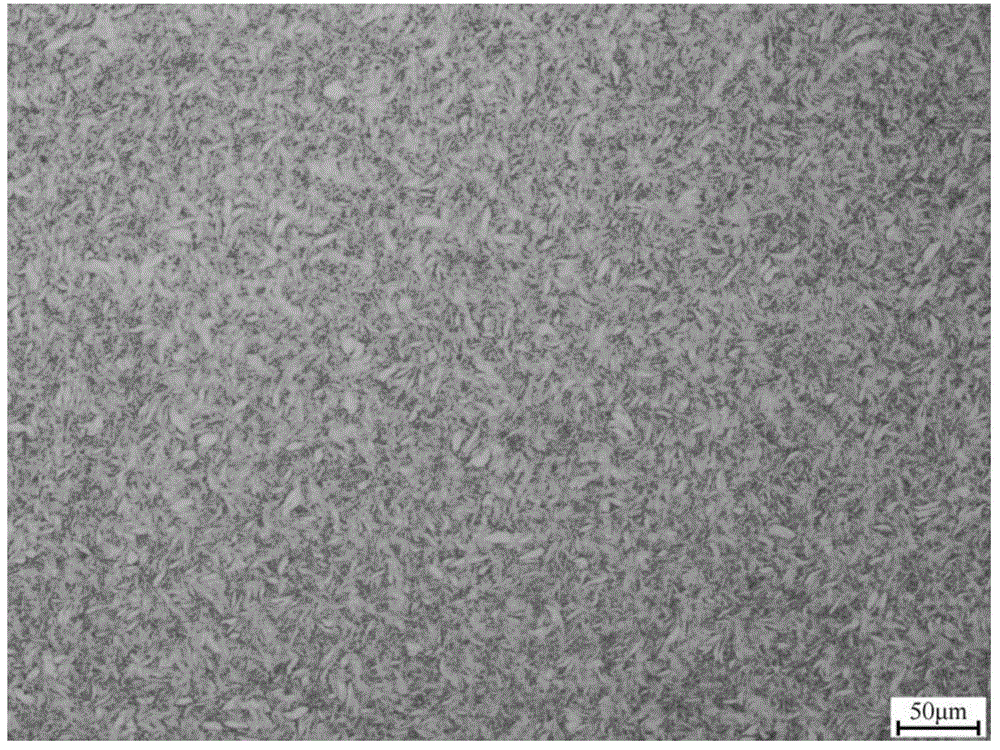

Embodiment 2

[0056] preparation TC20 titanium alloy curved plate;

[0057] Step 1, raw material preparation

[0058] According to the GB / T13810-2007 standard, TC20 titanium alloy rods with a diameter of Ф12mm are selected, the tensile strength is ≥900MPa, the elongation is ≥10%, and the roughness is 3.2μm. The pit should transition smoothly to obtain TC20 titanium alloy blank;

[0059] Step 2, Rolling

[0060] The TC20 titanium alloy billet obtained in step 1 is first rolled to Ф10mm by the cold square process, and the pass processing rate is 5%; then it is heated by electric contact, and the infrared temperature control system is adopted. The heating temperature is 800 ° C, and the power is turned off when the temperature reaches ;A two-roll rolling mill is used to quickly flat-roll to a thickness of 5.0mm-5.5mm×width 15mm-16mm, and the processing rate of the flat-rolling pass is 18%; The processing rate of rolling 1 is 5%; followed by 2 times of rolling, electric contact heating to ...

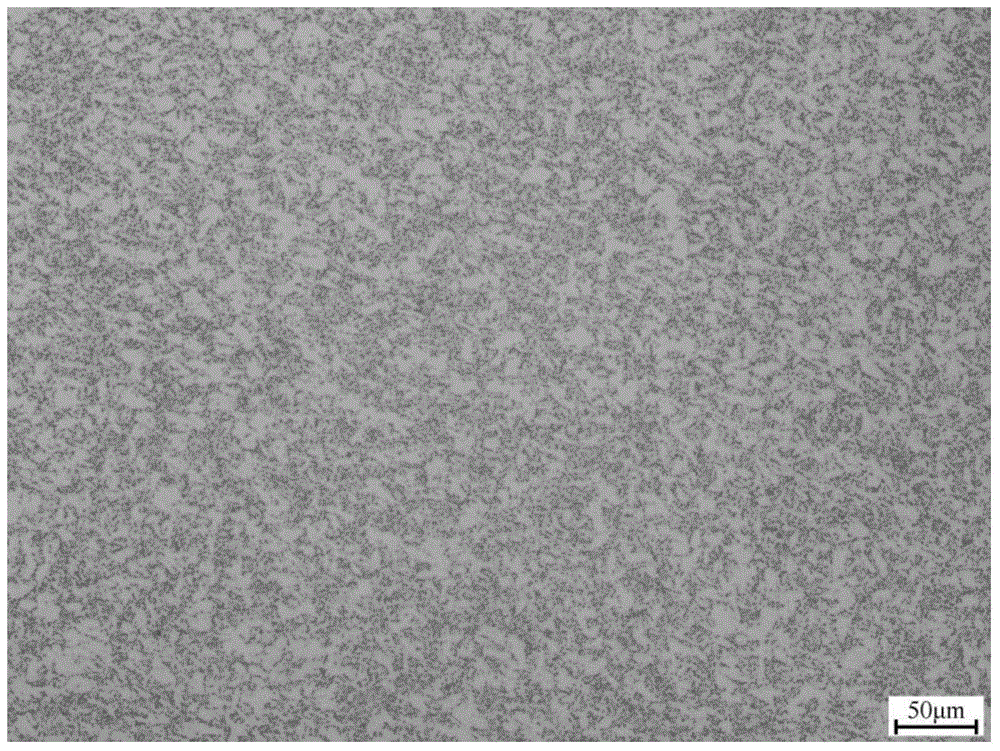

Embodiment 3

[0068] preparation TC4 titanium alloy curved plate;

[0069] Step 1, raw material preparation

[0070] According to the GB / T13810-2007 standard, TC4 titanium alloy rods with a diameter of Ф15mm are selected, the tensile strength is ≥860MPa, the elongation is ≥10%, and the roughness is 3.2μm. The pit should transition smoothly to obtain TC4 titanium alloy blank;

[0071] Step 2, Rolling

[0072] The TC4 titanium alloy billet obtained in step 1 is first rolled to Ф14mm by the cold square process, and the pass processing rate is 8%; then it is heated by electric contact, and the infrared temperature control system is used. The heating temperature is 900 ° C, and the power is turned off ;A two-roll rolling mill is used to quickly flat-roll to a thickness of 7.0mm-7.5mm×width 20mm-21mm, and the processing rate of the flat-rolling pass is 30%; The processing rate of rolling 1 is 30%; followed by 2 times of rolling, electric contact heating to 900°C, and power off at temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com