Bearing inner and outer ring grinding automatic line

An inner jacket and automatic line technology, applied in the field of bearing processing, can solve the problems of difficult machine tool maintenance, high maintenance cost, low qualification rate, etc., and achieve the effect of strong fault self-diagnosis ability, easy adjustment and maintenance, and fast command execution speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

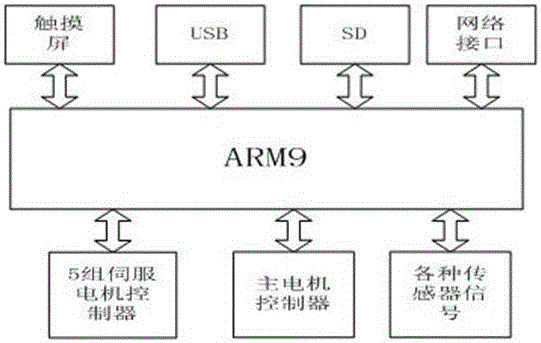

[0023] An automatic line for grinding inner and outer rings of bearings, including an inner ring line and an outer ring line. The inner ring line is connected with a 3MZ135 automatic ball bearing inner ring groove grinder, a 3MZ205 automatic ball bearing inner circle grinder and a fully automatic inner diameter pneumatic motor Outer inspection machine, 3MZ315 automatic ball bearing inner ring groove superfinishing machine; outer ring line is connected with 3MZ147 outer ring groove grinder and 3MZ329 outer ring groove superfinishing machine, inner ring line and outer ring line are connected with The main processor based on the ARM9 core is connected with a peripheral power drive circuit and a sensing signal receiving isolation circuit, and a software platform is integrated in the main processor based on the ARM9 core. The block diagram of the system hardware structure is as follows: figure 1 shown.

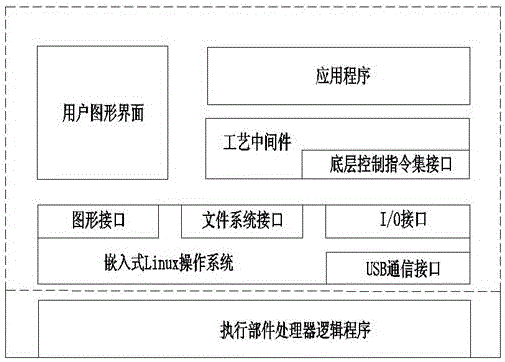

[0024] The software platform mainly includes the system porting program modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com