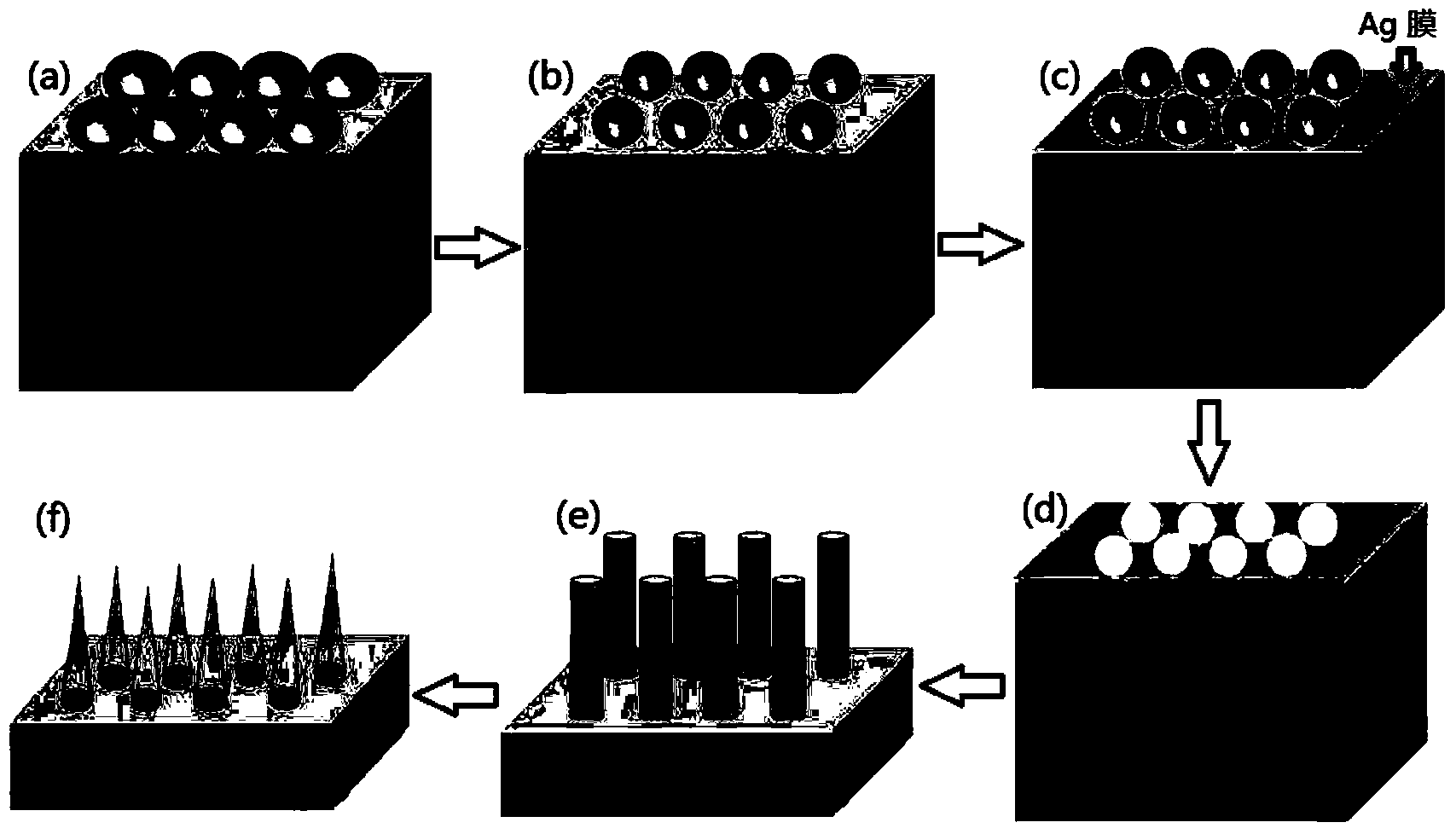

Preparation method of silicon nanowire array with excellent field emission performance and tip structure

A silicon nanowire array and field emission technology, applied in the field emission field, can solve the problems of staying, poor repeatability, etc., and achieve the effects of low cost, high yield, and improved monolayer property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) The silicon substrate and the glass slide were ultrasonically cleaned with acetone, alcohol, and deionized water one by one and immersed in concentrated H 2 SO 4 and H 2 o 2 Hydrophilic treatment is carried out in a mixed solution with a volume ratio of 4:1;

[0029] (2) Arrange a single layer of close-packed PS beads on the silicon substrate, the method is as follows: dry the glass sheet and place it in the center of the watch glass, add deionized water to the watch glass until the water level is slightly higher than the glass sheet Surface: Slowly add the diluted aqueous solution of PS beads with a mass fraction of 0.5% and a diameter of 960 nm onto the glass sheet, the beads spread on the liquid surface, and stop the dripping after most of the liquid surface covers a single layer of beads; Drop 1mL of sodium dodecyl sulfate solution with a mass fraction of 1% from the edge of the watch glass, put the silicon chip into the watch glass, push it to the side where...

Embodiment 2

[0037] (1) The silicon substrate and the glass slide were ultrasonically cleaned with acetone, alcohol, and deionized water one by one and immersed in concentrated H 2 SO 4 and H 2 o 2 Hydrophilic treatment is carried out in a mixed solution with a volume ratio of 4:1;

[0038] (2) Arrange a single layer of close-packed PS spheres on the silicon substrate by self-assembly method. The method is as follows: dry the glass sheet and place it in the center of the watch glass, add deionized water to the watch glass to the water surface Slightly higher than the surface of the glass sheet; slowly drop the aqueous solution of PS beads with a mass fraction of 0.5% and a diameter of 980nm obtained by dilution onto the glass sheet, and the beads spread on the liquid surface until most of the liquid surface covers a single layer of beads Stop dripping; drop 1mL sodium dodecyl sulfate solution with a mass fraction of 1% from the edge of the watch glass, put the silicon chip into the watch ...

Embodiment 3

[0045] (1) The silicon substrate and the glass slide were ultrasonically cleaned with acetone, alcohol, and deionized water one by one and immersed in concentrated H 2 SO 4 and H 2 o 2 Hydrophilic treatment is carried out in a mixed solution with a volume ratio of 4:1;

[0046] (2) Arrange a layer of single-layer close-packed PS spheres on the silicon substrate by self-assembly method, the method is as follows: dry the glass sheet and place it in the center of the watch glass, add deionized water to the watch glass to the water surface Slightly higher than the surface of the glass sheet; slowly drop the aqueous solution of PS beads with a mass fraction of 0.5% and a diameter of 1000nm to the glass sheet, and the beads spread on the liquid surface until most of the liquid surface covers a single layer of beads Stop dripping; drop 1mL sodium dodecyl sulfate solution with a mass fraction of 1% from the edge of the watch glass, put the silicon chip into the watch glass, push it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com