Chlorosilane purification system

A technology of chlorosilane and rectification tower, which is applied in the field of chlorosilane purification system to achieve the effect of solving high energy consumption, reducing production cost and achieving obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

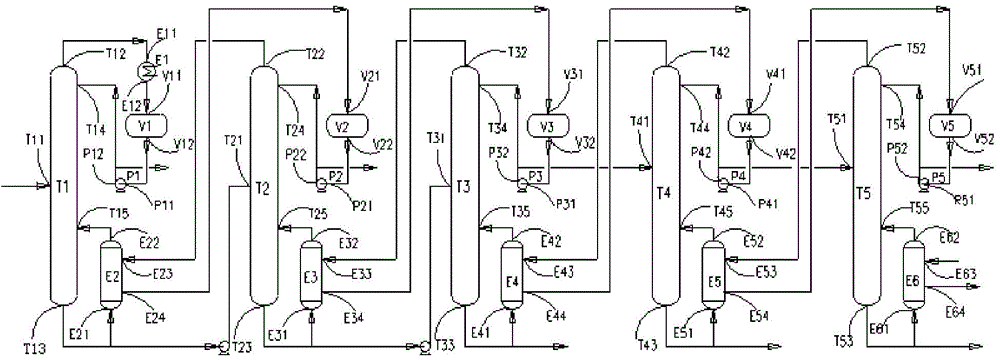

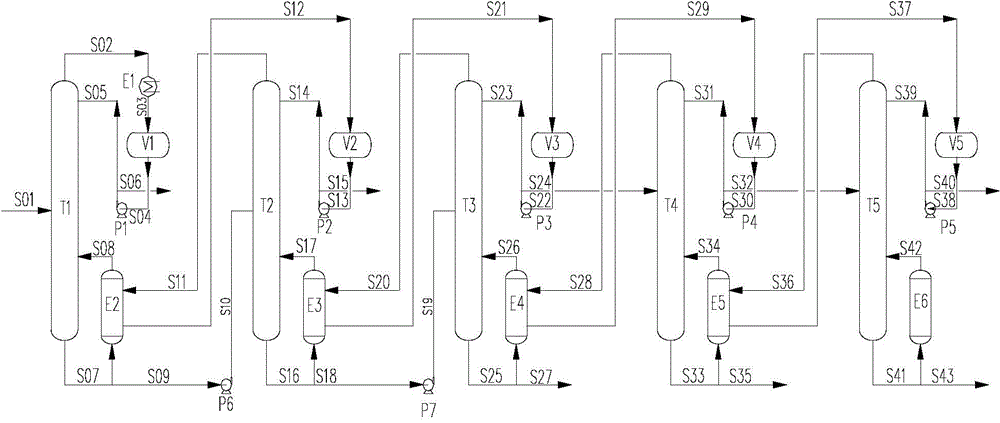

[0074] Same process image 3 , the tower feed volume is 20m 3 / h, the feed composition is as follows: the mass content of trichlorosilane is 98%, silicon tetrachloride and dichlorodihydrosilane are both 1%, and metal impurities such as B, P, and Fe are trace amounts.

[0075] The raw material first enters the first rectification tower T1, and the material flow is from the first rectification tower T1 to the fifth rectification tower T5, wherein the pressures of the first rectification tower T1 to the fifth rectification tower T5 increase sequentially.

[0076] The top pressure and temperature of the first rectification tower are 0.25MPa (absolute pressure) and 54.9°C respectively, ensuring that the cooling source of the top of the first rectification tower (that is, the tower with the lowest pressure) is circulating water; the fifth rectification tower The temperature of the bottom of the tower should be lower than 120°C, to ensure that the heat source of the fifth rectificat...

Embodiment 2

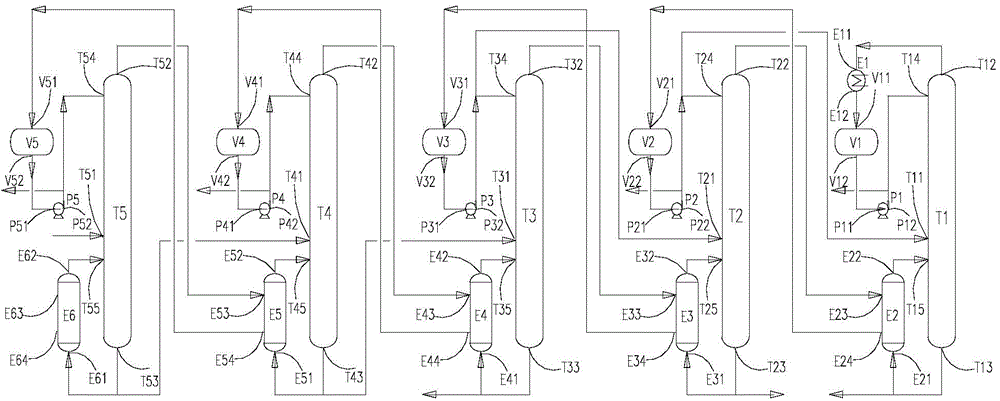

[0082] Same process Figure 4 , the tower feed volume is 20m 3 / h, the feed composition is as follows: the mass content of trichlorosilane is 98%, silicon tetrachloride and dichlorodihydrosilane are both 0.1%, and metal impurities such as B, P, and Fe are trace amounts.

[0083] The raw material first enters the fifth rectification tower T5, and the material flow is from the fifth rectification tower T5 to the first rectification tower T1, wherein the pressure from the fifth rectification tower T5 to the first rectification tower T1 decreases sequentially.

[0084] The pressure and temperature at the top of the first rectification tower are 0.25MPa (absolute pressure) and 54.9°C respectively, ensuring that the cooling source at the top of the first rectification tower (that is, the tower with the lowest pressure) is circulating water; the fifth rectification tower The temperature of the bottom of the tower should be lower than 120°C, to ensure that the heat source of the fift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com