Modified naphthalene-series water reducer and preparation method thereof

A high-efficiency water reducer and naphthalene-based technology, which is applied in the field of naphthalene-based water reducers, can solve problems such as reduced cement compatibility, weakened water reducer dispersion performance, and complex production processes, so as to improve production efficiency and reduce sodium sulfate. content, the effect of improving workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] A preparation method of modified naphthalene series high-efficiency water reducer, which comprises the following steps:

[0014] 1) Dissolving naphthalene: Add 93 parts of industrial naphthalene and 38 parts of washing oil into the reaction kettle and heat up to 130°C to melt;

[0015] 2) Sulfonation: start stirring when the temperature of the reactor rises to 160°C, and slowly add 175 parts of sulfuric acid within 50 minutes for sulfonation for 3.5 hours until the acidity of sulfonation is 31;

[0016] 3) Hydrolysis: Cool down the reaction kettle to 110°C and add 25 parts of water for hydrolysis. The time is controlled for 30 minutes until the acidity is 29;

[0017] 4) Condensation: When the temperature of the reactor is lowered to 90°C, add 90 parts of formaldehyde dropwise, and stir while adding dropwise. The dropping time is controlled at 1.5 hours, the condensation temperature is controlled at 105°C, and the condensation time is 5.5 hours;

[0018] 5) Neutralizat...

Embodiment 2~4

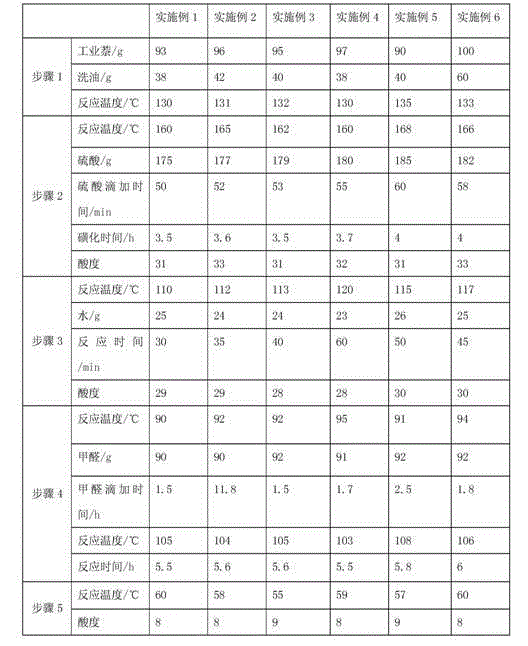

[0020] Adopt the same preparation method as Example 1, the difference is to use the addition amount of each component different in each step listed in Table 1, reaction time, temperature, acidity instead of the corresponding numerical values adopted in Example 1.

[0021] Table 1

[0022]

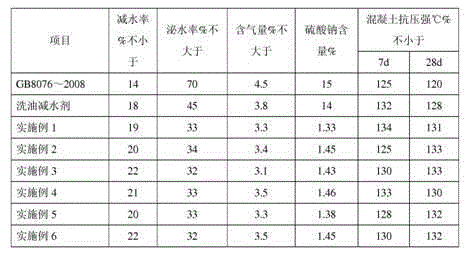

[0023] The performance data of the concrete modified with the concrete modified admixture obtained in Examples 1-6 are shown in Table 2. The used concrete before the modification of the measured data in the table is C30 strong ℃ concrete, and its combination The ratio is: cement: sand: gravel: water = 1: 1.18: 2.63: 0.41 (mass ratio):

[0024] Table 2

[0025]

[0026] It can be seen from the data in Table 2 that the performance data of the concrete modified with the concrete modified admixture prepared in Examples 1-6 are better than the national standard, and the concrete has less water consumption, low air content and higher strength.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com