Foamed polyolefin composition and polyolefin foamed material, preparation method of foamed polyolefin composition as well as product prepared by adopting foamed polyolefin composition

A technology for foaming polyolefin and composition, applied in the field of polyolefin foam materials, can solve the problems of poor fluidity, low foaming ratio, etc., and achieve the effects of increasing selectivity, high foaming ratio, and widening the processing operation window.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention also provides the preparation method of above-mentioned polyolefin foam material, and this method comprises the following steps:

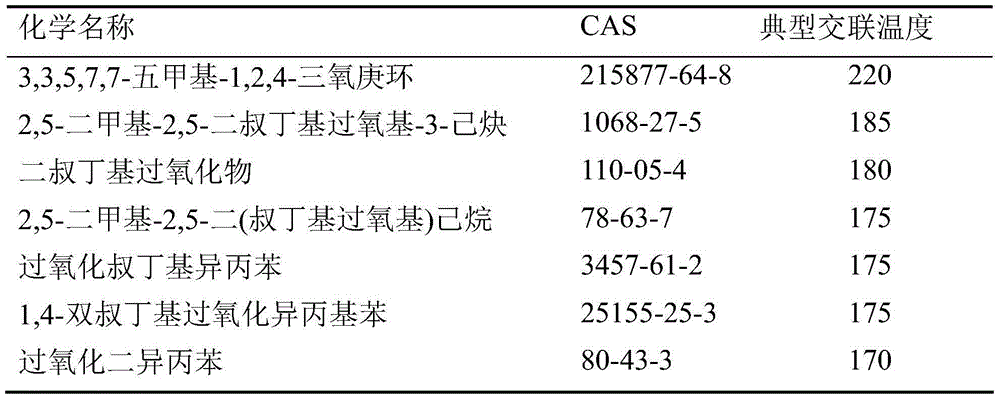

[0038] 1) Add the foamed polyolefin composition containing polyolefin resin, cross-linking agent system and organic chemical foaming agent system into a mixer and stir until uniformly mixed. The cross-linking agent system is at least two kinds of organic peroxide A mixture of coupling agents, wherein the melting point T of the polyolefin resin a , the decomposition temperature T of the organic chemical blowing agent system b , the typical crosslinking temperature T of at least two organic peroxide crosslinking agents in the crosslinking agent system c1 and T c2 The relation satisfies: T a c1 b c2 ;

[0039] 2) Melt blending the foamed polyolefin mixture obtained in step 1), and its operating temperature T 0 Meet: T a 0 c1 ;

[0040] 3) Gradually heat the blend obtained in step 2) until the operating temperature T...

Embodiment 1

[0074] Replace the crosslinking agent 2,5-dimethyl-2,5-di-tert-butylperoxy-3-hexyne (DYBP) in Comparative Example 1 with 2,5-dimethyl-2,5- A crosslinking agent system composed of a mixture of di-tert-butylperoxy-3-hexyne (DYBP) and dicumyl peroxide (DCP), and the weight ratio of the two is 3:1, and the other compositions and ratios remain unchanged Repeat the experiment.

[0075] Among them, the melting point Ta of polyethylene (LH3750) is 124°C, the melt index is 5g / 10min (2.16kg / 10min), the decomposition temperature Tb of the organic chemical foaming agent system is 180°C, and the crosslinking agent dicumyl peroxide (DCP) typical crosslinking temperature T c2 The typical crosslinking temperature T of the crosslinking agent 2,5-dimethyl-2,5-di-tert-butylperoxy-3-hexyne (DYBP) is 185°C c1 is 170°C.

[0076] The formula is based on the base resin (polyethylene LH3750) as 500 parts by weight, see Table 2;

[0077] The performance test results of polyolefin foam materials are...

Embodiment 2

[0081] Replace the crosslinking agent 2,5-dimethyl-2,5-di-tert-butylperoxy-3-hexyne (DYBP) in Comparative Example 3 with 2,5-dimethyl-2,5- A crosslinking agent system composed of a mixture of di-tert-butylperoxy-3-hexyne (DYBP) and dicumyl peroxide (DCP), and the weight ratio of the two is 1:1, and the other compositions and ratios remain unchanged Repeat the experiment.

[0082] The formula is shown in Table 2 based on 500 parts by weight of the matrix resin;

[0083] The performance test results of polyolefin foam materials are shown in Table 3.

[0084] From the foamed polyolefin composition (the foamed polyolefin composition contains linear low density polyethylene, 2,5-dimethyl-2,5-di-tert-butylperoxy-3-hexyne (DYBP) The cross-linking agent system composed of a mixture of dicumyl peroxide (DCP) and the organic chemical foaming agent azodicarbonamide (AC)) can be used for filling automobile bodies, incubators, yachts and large seafood transport etc.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com