Device for measuring torsional pendulum micro impulse through linear frequency modulation multi-beam laser heterodyning and torsional pendulum micro impulse measuring method based on device

A linear frequency modulation, laser heterodyne technology, applied in measuring devices, force/torque/work measuring instruments, instruments, etc., can solve problems such as low measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

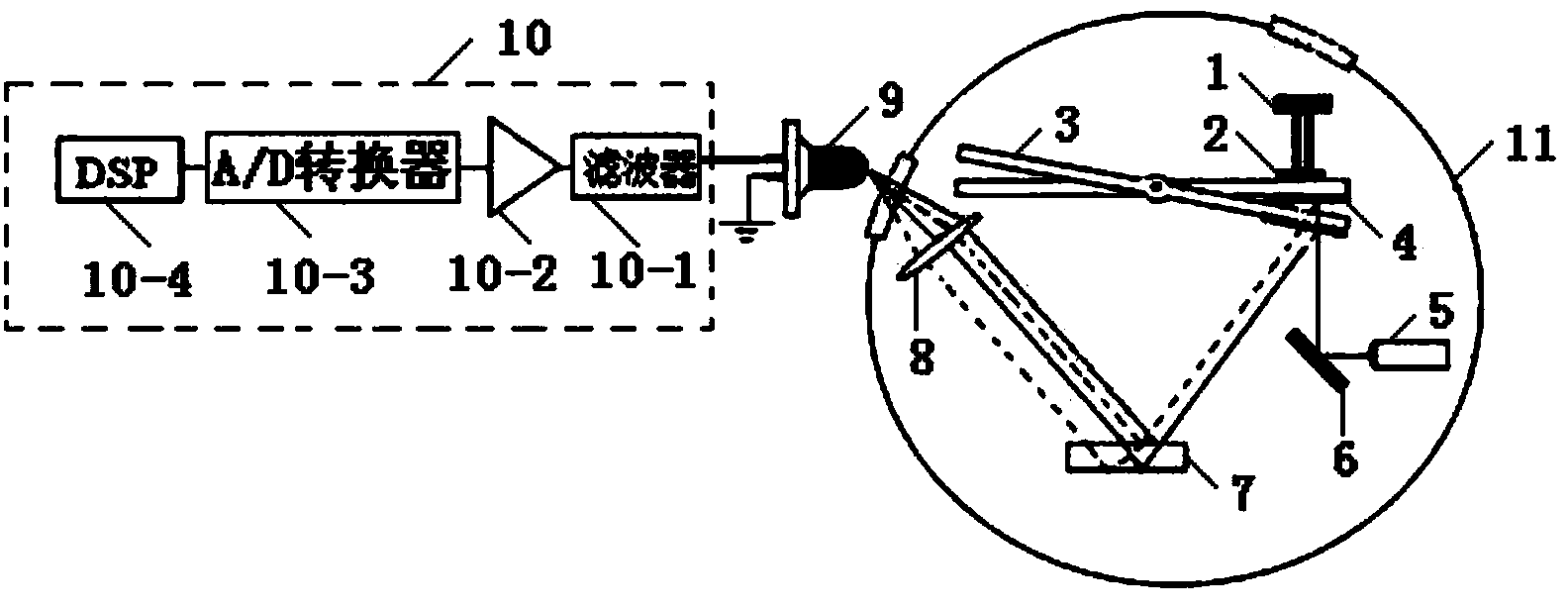

[0049] Specific implementation mode 1. Combination figure 1 Describe this specific embodiment, the device of chirped multi-beam laser heterodyne measurement torsion micro-impulse described in this specific embodiment includes chirp laser 5, first plane reflector 6, second plane reflector 4, plane standard mirror 7 , standard beam 3, vacuum chamber 11, pulsed laser 1, working fluid target 2, converging lens 8, photodetector 9 and signal processing system 10,

[0050] The chirped laser 5, the first plane reflector 6, the second plane reflector 4, the plane standard mirror 7, the standard beam 3, the pulsed laser 1, the working medium target 2 and the converging lens 8 are all placed in the vacuum chamber 11,

[0051] The center of the standard beam 3 is fixed with a rotating shaft,

[0052] The working fluid target 2 is pasted on the upper surface of the standard beam 3, the second plane mirror 4 is pasted on the lower surface of the standard beam 3, and the working fluid target ...

specific Embodiment approach 2

[0054] Specific embodiment two, combine figure 1 Describe this specific embodiment. The difference between this specific embodiment and the device for measuring torsion micro-impulse by chirp multi-beam laser heterodyne described in Embodiment 1 is that the signal processing system 10 includes a filter 10-1, a pre- Amplifier 10-2, A / D converter 10-3 and DSP10-4, the electrical signal input end of filter 10-1 is connected with the electrical signal output end of photodetector 9 as the electrical signal input end of signal processing system 10, The filter signal output end of the filter 10-1 is connected with the filter signal input end of the preamplifier 10-2, and the amplified signal output end of the preamplifier 10-2 is connected with the analog signal input end of the A / D converter 10-3 , the digital signal output terminal of the A / D converter 10-3 is connected with the digital signal input terminal of the DSP10-4.

specific Embodiment approach 3

[0055] Specific embodiment three, combine figure 1 Describe this specific embodiment. The difference between this specific embodiment and the device for measuring the torsion micro-impulse by chirp multi-beam laser heterodyne described in the first specific embodiment is that the vacuum window is used to converge the light in the vacuum chamber 11 to The photosensitive surface of the photodetector 9 outside the vacuum chamber 11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com