A TEM thin-film window for in-situ high-resolution observation of the electrophase transition process of phase change materials

A phase change material and transmission electron microscope technology, which is applied in the use of radiation for material analysis, circuits, discharge tubes, etc., can solve the problem that phase change materials cannot be directly observed, and achieve high-resolution observation, avoid damage, and The preparation process is simple. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation method of the transmission electron microscope for in-situ electrical test of the present invention comprises the following steps:

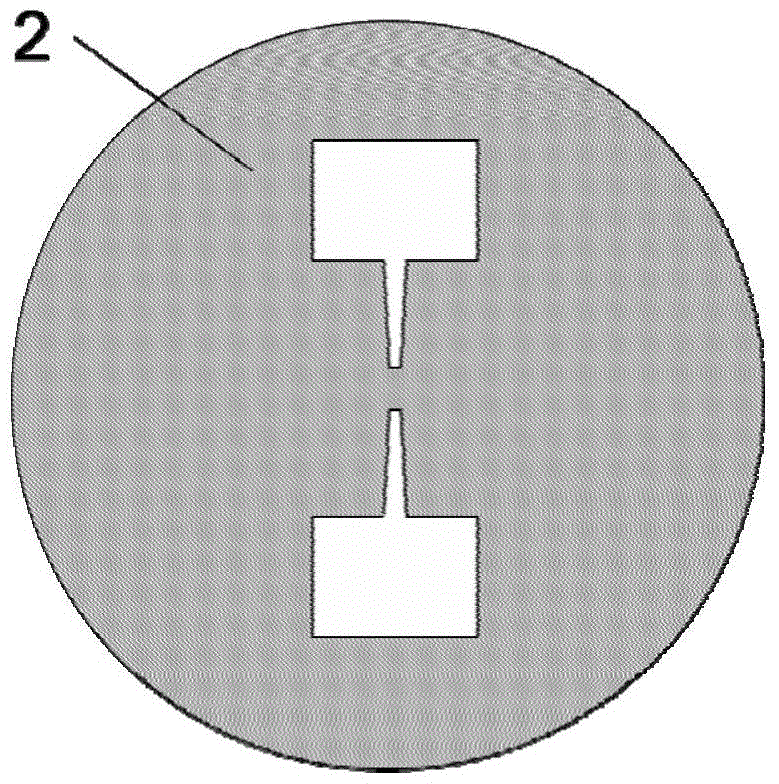

[0037] Step 1: Use an easy-to-process nickel sheet as a mask, and process the shape of the electrode on the mask. The hollow part is obtained by laser cutting or metal etching. The thickness of the mask is about 0.2mm, and the surface of the mask remains flat .

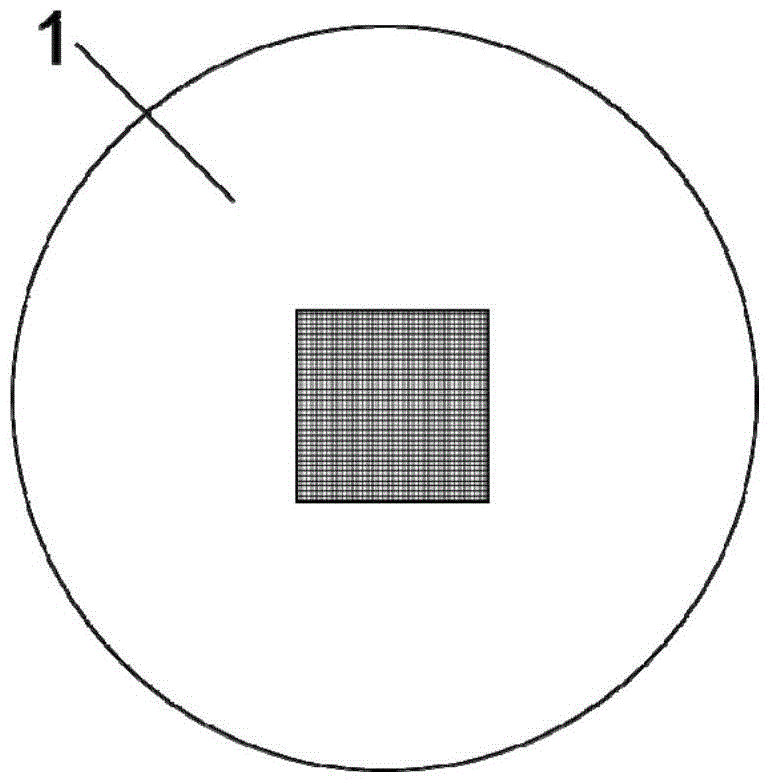

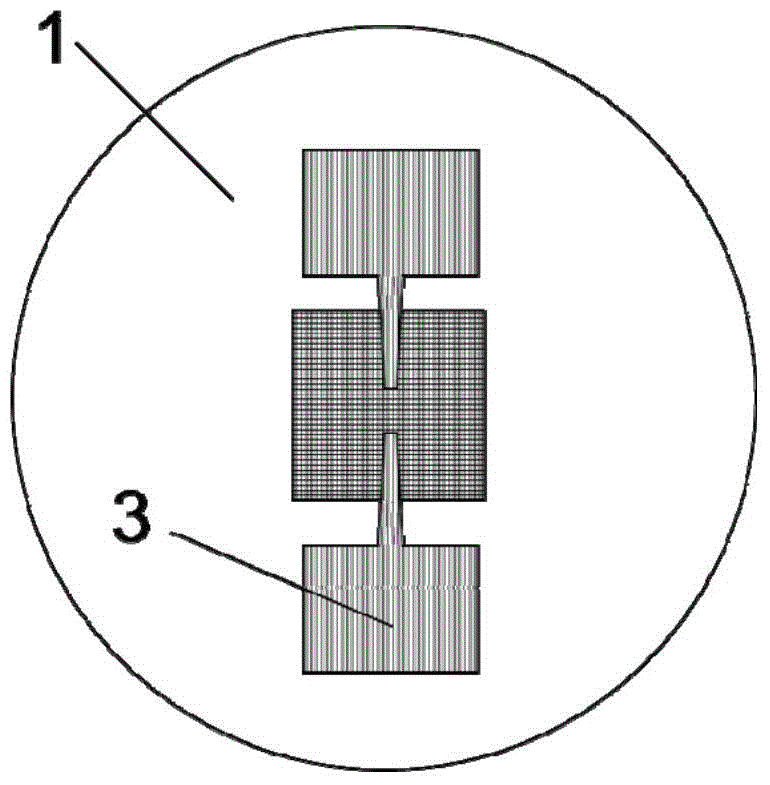

[0038] Step 2: Cover the mask on SiN x On the thin film window, a 200nm-thick Au is plated as an electrode by using a coating machine, and then the mask is removed to obtain an electrode, and the thin film material is between the electrodes. Due to the existence of the sputtering shadow area, the distance between the electrodes is designed to be 10 μm.

[0039] Step 3: FIB is used for electron beam deposition at both ends of the obtained electrodes to prepare Pt electrodes with a spacing of 1 μm. Then using a focused ion beam, the Si between the electrodes 3 N ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com