Method for detecting flaws of printed fabric based on Gabor filter

A detection method, 2-d-gabor technology, applied in instrumentation, image data processing, computing, etc., can solve the problems of high false alarm rate of detection defects, local defects of gray-scale images, poor positioning accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

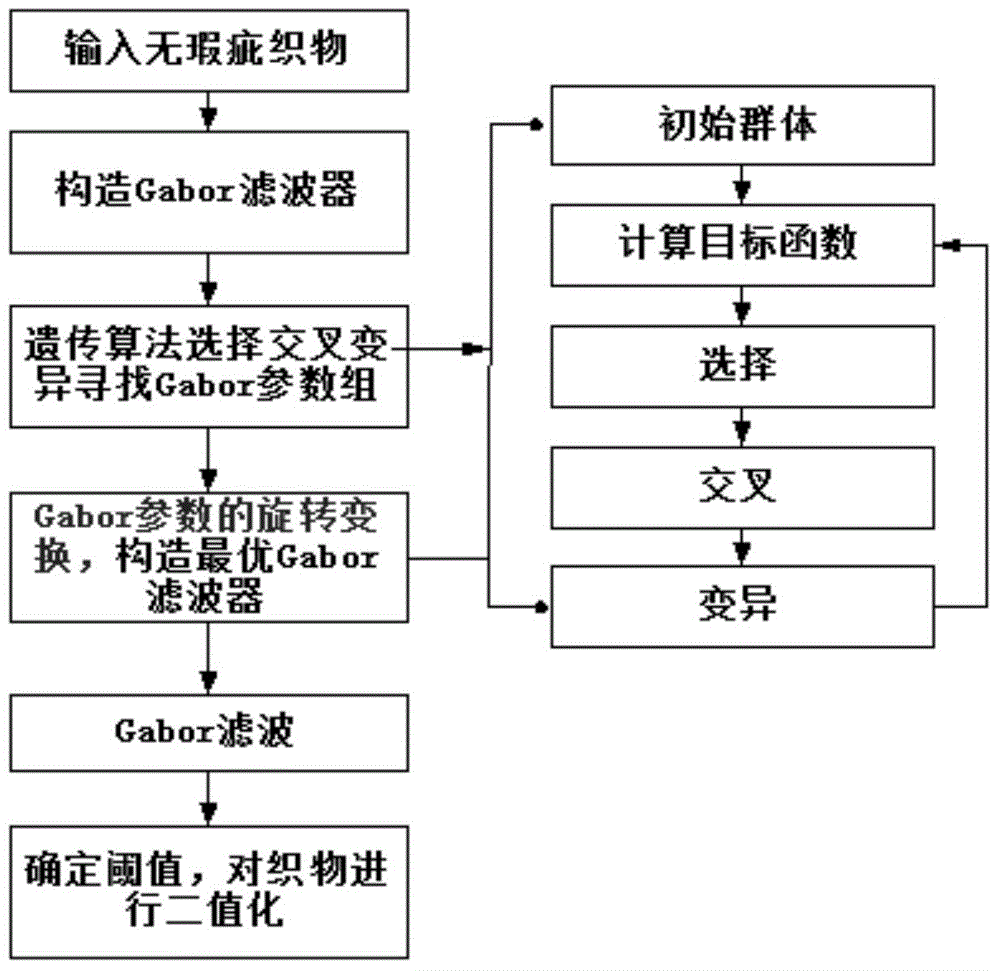

[0140] First input a flawless printed fabric image, 100 parameter individuals are substituted into the objective function, and the 20 individuals with the highest objective function are removed each time, then the individuals are crossed, mutated, and then substituted into the objective function, selected, crossed and mutated, until the parameter individual becomes 0 , save the minimum parameter individual of the objective function; convert the obtained parameter individual into a decimal number, then convert the center frequency and direction, and substitute the obtained parameters into the Gabor filter, first filter the image of the flawless printed fabric, and obtain the filtered center The maximum gray value and the minimum gray value of the window, the maximum gray value and the minimum gray value are used as the maximum threshold and the minimum threshold, and then the image of the printed fabric to be tested is filtered, and the image to be tested is binarized according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com