Preparation method of instantgreen teaconcentrated juice

A technology for concentrated juice and green tea, applied in the direction of tea extraction, can solve the problems of poor extraction effect, short production process, low process energy consumption, etc., and achieve product characteristics with obvious flavor, short production process, and low process energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Put 5 kg of freshly picked summer tea leaves in a green tank at 30°C for 8 hours until the water content of the fresh tea leaves is 65%; puff them at 150°C and 0.35 MPa for 2.5 minutes, and immediately reduce the pressure; homogenate at 4°C for 60 seconds, The crushing degree is 3mm, then transfer to the extraction tank, add water to 600kg, adjust the pH to 5.5, add 50g of pectinase, stir at 200r / min, control the extraction temperature at 55°C, keep it for 90min, heat up to 95°C for 10min, and cool down rapidly , through 5000r / min butterfly centrifugation, then transported to 0.2μm ceramic membrane and 300Da concentrated membrane, the concentrated solution was sterilized by UHT to obtain instant green tea concentrated juice 1 with a solid content of 22.4%.

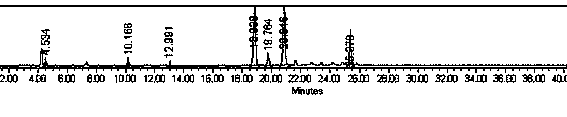

[0022] After testing, the amino acid in the instant green tea concentrated juice 1 is 10.7 mg / mL, the chlorophyll is 2.6 mg / mL, and the tea polyphenols are 58.5 mg / mL. The liquid chromatogram is as follows: figure 1...

Embodiment 2

[0024] Put 5kg of fresh autumn tea leaves freshly harvested in a stand green tank at 25°C for 10 hours until the moisture content of the fresh tea leaves is 75%, puff them at 130°C and 0.5MPa for 2 minutes, and immediately reduce the pressure; homogenize at -10°C for 30 seconds, and crush The temperature is 1mm, then transferred to the extraction tank, add water to 600kg, adjust the pH to 5.0, add 25g of protease, stir at 300r / min, extract at 65°C, keep for 60min, heat up to 100°C for 5min, cool rapidly, and pass through 5000r / min Min Butterfly centrifugation, transported to 0.02μm ceramic membrane and 150Da concentrated membrane in turn, the concentrated solution was sterilized by UHT to obtain instant green tea concentrated juice 2 with a solid content of 23.0%.

[0025] After testing, the amino acid in the instant green tea concentrated juice 2 is 11.3 mg / mL, the chlorophyll is 2.7 mg / mL, and the tea polyphenol is 56.0 mg / mL. The liquid chromatogram is as follows figure 1 s...

Embodiment 3

[0027] Put 5kg of freshly harvested summer tea leaves in a green tank at 20°C for 15 hours until the moisture content of the fresh tea leaves is 70%; puff them at 180°C and 0.2MPa for 3.5 minutes, and immediately reduce the pressure; homogenate at 10°C for 90 seconds, The crushing degree is 5mm, then transfer to the extraction tank, add water to 600kg, adjust the pH to 6.5, add 50g of cellulase and 75g of protease, stir at 100r / min, control the extraction temperature at 45°C, keep it for 150min, heat up to 90°C for 10min , rapidly cooled, and then transferred to a 0.1μm ceramic membrane and a 200Da concentrated membrane in sequence through 5000r / min butterfly centrifugation. The concentrated solution was sterilized by UHT to obtain instant green tea concentrated juice 3 with a solid content of 25.6%.

[0028] After testing, the amino acid in the instant green tea concentrated juice 3 is 11.4 mg / mL, the chlorophyll is 2.7 mg / mL, and the tea polyphenols are 60.1 mg / mL. The liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com