Biological treatment system for waste gas

A biological system and treatment system technology, applied in the field of new waste gas biological treatment technology, can solve the problems of complex operation, high maintenance cost, low removal rate, etc., and achieve the effect of flexible operation, stable performance and guaranteed performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] According to the claims of the present invention and the content disclosed in the summary of the invention, the technical solution of the present invention is specifically as follows:

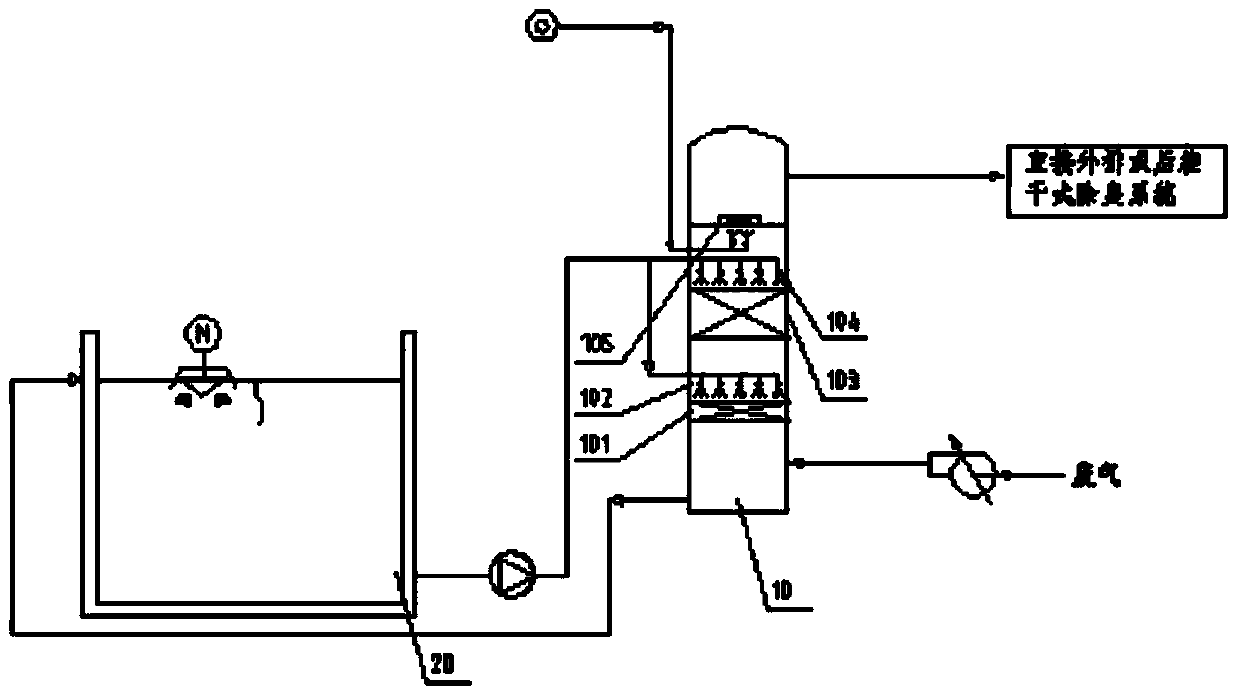

[0016] Fig. 1 is a schematic diagram of the process route of the waste gas biological system of the present invention, please refer to Fig. 1, wherein the waste gas is connected to the air inlet of the waste gas biological scrubber 10 through the waste gas blower; Type deodorization unit is connected; an aerobic system 20 activated sludge mixture is connected with the waste gas biological scrubber through the spray pump, and the spray liquid after washing is connected with the aerobic system pipeline; the waste gas biological system specifically includes: a Exhaust gas biological scrubber is used for packing to increase the gas-liquid contact area. A waste gas biological scrubber (Bio-Scrubber biological scrubber), characterized in that it includes: a scrubber, the bottom of the scrubber...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap