Foaming agent for earth pressure balance shield

A technology of earth pressure balance shield and foam agent, which is applied in the field of foam agent for earth pressure balance shield and silty sand formation, which can solve the problems of poor stability and low expansion rate, and achieve high foaming ratio, small pores, Good compatibility and mutual cooperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

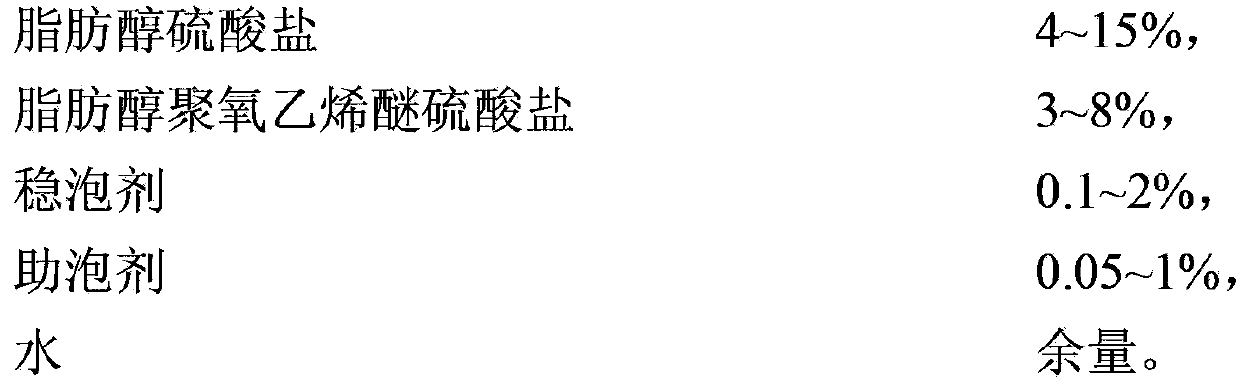

[0026] The weight percent of each raw material component is:

[0027]

[0028] At room temperature, the components are mixed and dissolved in proportion, and stirred evenly, and it is ready. The expansion rate of the foam generated by the proportion can reach 84-90 times, and the half-life of the foam can reach 66-80 minutes. Its performance index is obviously better than that of the representative foam agent of the same type in China, such as the product produced according to the method recorded in the patent No. 200910223854 applied by China University of Mining and Technology (Beijing).

Embodiment 2

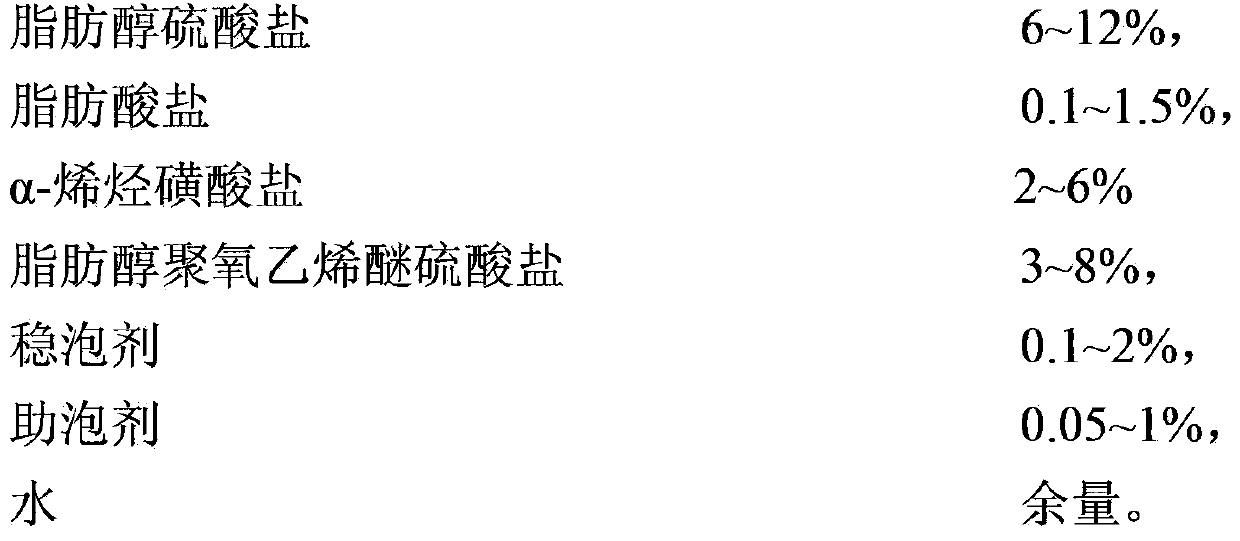

[0030] The weight percent of each raw material component is:

[0031]

[0032]

[0033] At room temperature, the components are mixed and dissolved in proportion, and stirred evenly, and it is ready. The expansion rate of the foam generated by this proportion can reach 70-80 times due to the difference in external temperature, and the half-life of the foam can reach 50-70 minutes.

Embodiment 3

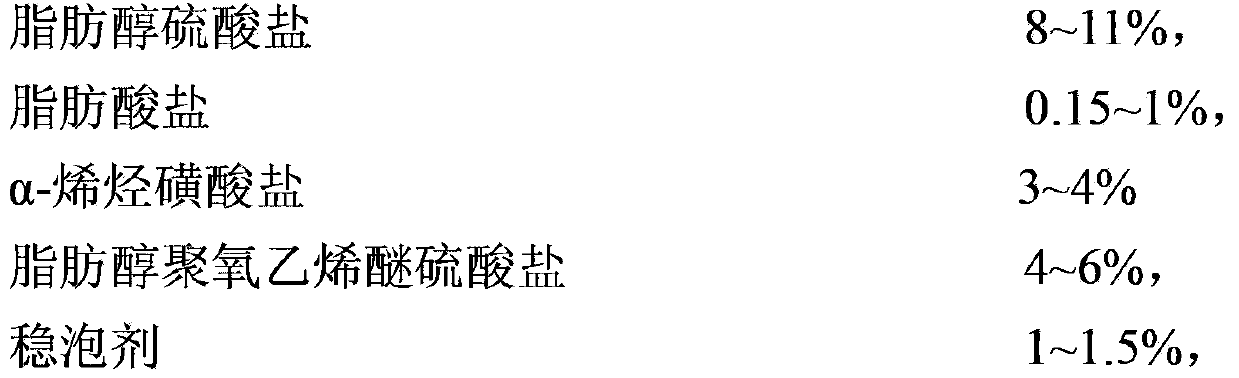

[0035] The weight percent of each raw material component is:

[0036]

[0037] At room temperature, the components are mixed and dissolved in proportion, and stirred evenly, and it is ready. The expansion rate of the foam generated by this proportion can reach 30-45 times due to the difference in external temperature, and the half-life of the foam can reach 20-40 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com