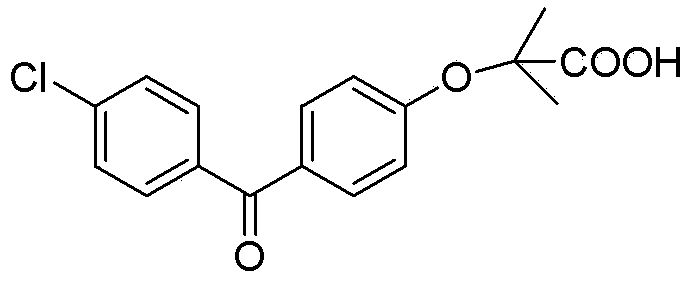

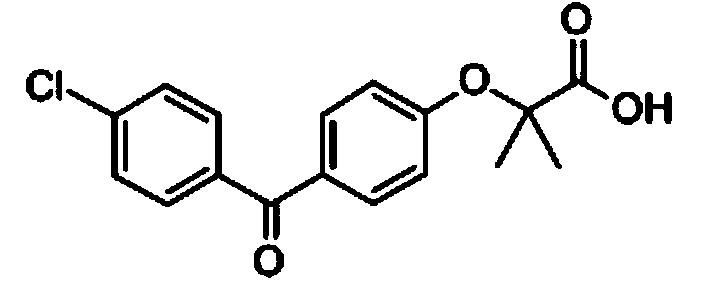

Refining method for high-purity clofibric acid blood-lipid regulating drug--fenofibric acid

A technology of clofibric acid and fenofibric acid, which is applied in the field of medicine, can solve the problems of low product purity and consistent crystal form, and achieve the effect of easy transformation and production and low requirements for reaction equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Organic solvent recrystallization: Add 400g of absolute ethanol and 50g of fenofibric acid into a 1000ml three-neck flask, reflux to dissolve, add 5g of activated carbon, decolorize for 30min, filter while hot, cool down to crystallize, filter, and dry at 60°C. 38 g of off-white solid was obtained, with a yield of 76% and a purity of 99.30%.

[0018] (2) Mixed solvent recrystallization: Add 140g of a mixed solvent of absolute ethanol and ethyl acetate (volume ratio 1:1) into a 250ml three-neck flask, then add 35g of the solid obtained in the previous step, reflux to completely dissolve, cool down and crystallize, Filter and dry at 60°C to obtain 24.6 g of off-white solid with a yield of 70.3% and a purity of 99.81%.

[0019] (3) Methanol recrystallization: add 160g of methanol and 20g of mixed solvent into a 250ml three-necked flask to recrystallize the off-white solid, reflux to completely dissolve, cool down to crystallize, filter, and dry at 60°C to obtain 15g of...

Embodiment 2

[0021] (1) Organic solvent recrystallization: Add 350g of acetone and 50g of fenofibric acid into a 1000ml three-necked flask, reflux to dissolve, add 5g of activated carbon, decolorize for 30min, filter while hot, cool down and crystallize, filter, and dry at 60°C to obtain White solid 35g, yield 70%, purity 99.36%.

[0022] (2) Mixed solvent recrystallization: Add 90g of a mixed solvent of absolute ethanol and ethyl acetate (volume ratio 1:1) into a 250ml three-neck flask, then add 30g of the solid obtained in the previous step, reflux to completely dissolve, and cool down to crystallize. Filter and dry at 60°C to obtain 22.2 g of off-white solid with a yield of 74% and a purity of 99.76%.

[0023] (3) Recrystallization of methanol: add 160g of methanol and 20g of mixed solvent into a 250ml three-neck flask to recrystallize the off-white solid, reflux to completely dissolve, crystallize at lower temperature, filter, and dry at 60°C to obtain 15.4g of white solid, yield 77%,...

Embodiment 3

[0025] (1) Organic solvent recrystallization: add 340g chloroform and 50g fenofibric acid into a 1000ml three-neck flask, reflux to dissolve, add 5g activated carbon, decolorize for 30min, filter while hot, cool down to crystallize, filter, dry at 60°C, 32 g of off-white solid was obtained, with a yield of 64% and a purity of 99.27%.

[0026] (2) Mixed solvent recrystallization: Add 100g of mixed solvent of n-propanol and ethyl acetate (volume ratio 1:1) into a 250ml three-neck flask, then add 30g of the solid obtained in the previous step, reflux to completely dissolve, cool down and crystallize, Filter and dry at 60°C to obtain 21 g of off-white solid with a yield of 70% and a purity of 99.78%.

[0027] (3) Recrystallization of methanol: add 160g of methanol and 20g of mixed solvent into a 250ml three-neck flask to recrystallize the off-white solid, reflux to completely dissolve, crystallize at lower temperature, filter, and dry at 60°C to obtain 15.2g of white solid, yield ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com