A kind of preparation method of polyimide film

A technology of polyimide film and polyamide film, which is applied in the field of preparation of polyimide film, can solve the problems of difficult control of pore size, shape and porosity, unsuitability for large-scale production, high cost of raw materials, etc., to achieve The product composition is easy to control, the pore size is easy to adjust, and the effect of low dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

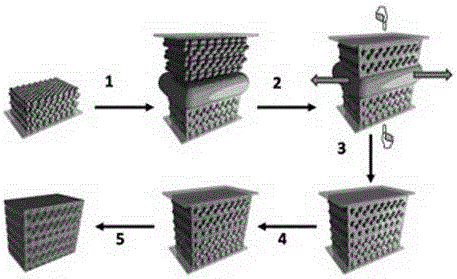

Method used

Image

Examples

Embodiment 1

[0038] (1) Prepare the template

[0039] SiO 2 The microspheres are dispersed into the solvent to prepare a uniform dispersion of the microspheres. Put the clean glass piece into the culture bottle at an angle, inject an appropriate amount of dispersion liquid into the bottle, put the culture bottle into the incubator, and wait for the solvent to volatilize to make the template. The particle size of the microspheres is 20nm. The dispersant used is an aqueous solution of Tween, and the volume fraction of Tween is 0.01%. The temperature in the incubator was 30°C.

[0040] (2) Preparation of polyamic acid solution

[0041] Add dianhydride and diamine monomers in proportion to the polar solvent and heat the stirring plate at 25° C. for 10 hours to obtain a polyamic acid solution. The polyamic acid solution was defoamed under vacuum for 2 hours at room temperature to obtain a membrane-forming solution. The polar solvent of choice is dimethylformamide. The mass fraction of po...

Embodiment 2

[0049] (1) Prepare the template

[0050] Disperse polystyrene microspheres in a solvent to prepare a uniform dispersion of microspheres. Put the clean glass piece into the culture bottle at an angle, inject an appropriate amount of dispersion liquid into the bottle, put the culture bottle into the incubator, and wait for the solvent to volatilize to make the template. The particle size of the microspheres is 1500nm. The dispersant used is an aqueous solution of Tween, and the volume fraction of Tween is 0.15%. The temperature of the incubator was 60°C.

[0051] (2) Preparation of polyamic acid solution

[0052] Dissolving polyamic acid, the precursor of polyimide, in a suitable polar solvent, heating a stirring plate at 50° C. for 10-25 hours to obtain a polyamic acid solution. The polyamic acid solution is degassed under vacuum for 1-15 hours at room temperature to obtain a membrane-forming solution. The selected polar solvent is dimethylformamide, N-methylpyrrolidone or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com