Energy saving device for directly recycling waste heat from condenser of power plant to supply heat and energy saving method

An energy-saving device and condenser technology, applied in household heating, heating methods, heating systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

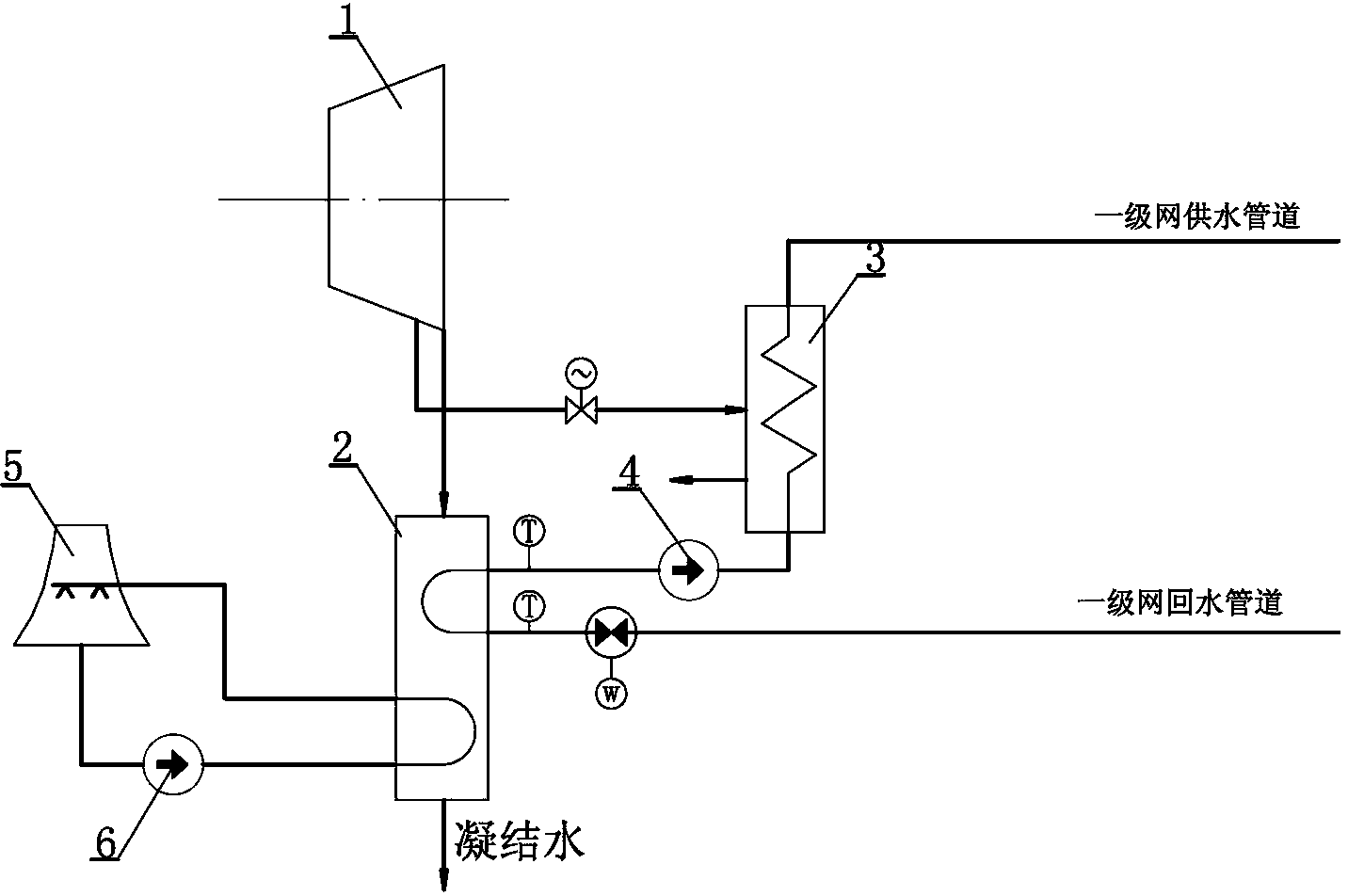

[0018] Embodiment 1 (water cooling system power plant)

[0019] Such as figure 1 As shown, an energy-saving device that directly recovers waste heat from the condenser of a power plant for heat supply, is provided with a main heat exchanger 3 for heating on the primary heating network, and the heat source inlet of the main heat exchanger 3 is connected to the steam turbine 1 of the power plant The steam extraction port is connected; the exhaust port of the steam turbine 1 of the power plant is connected with the inlet of the condenser 2; the hot water heat exchange channel is set in the condenser 2, and the return water pipe of the primary network is connected with the inlet of the hot water heat exchange channel , the outlet of the hot water heat exchange channel is connected to the inlet of the main heat supply heat exchanger 3 through the heating main circulation pump 4, and the return water pipe of the primary network is connected to the hot water heat exchange channel of ...

Embodiment 2

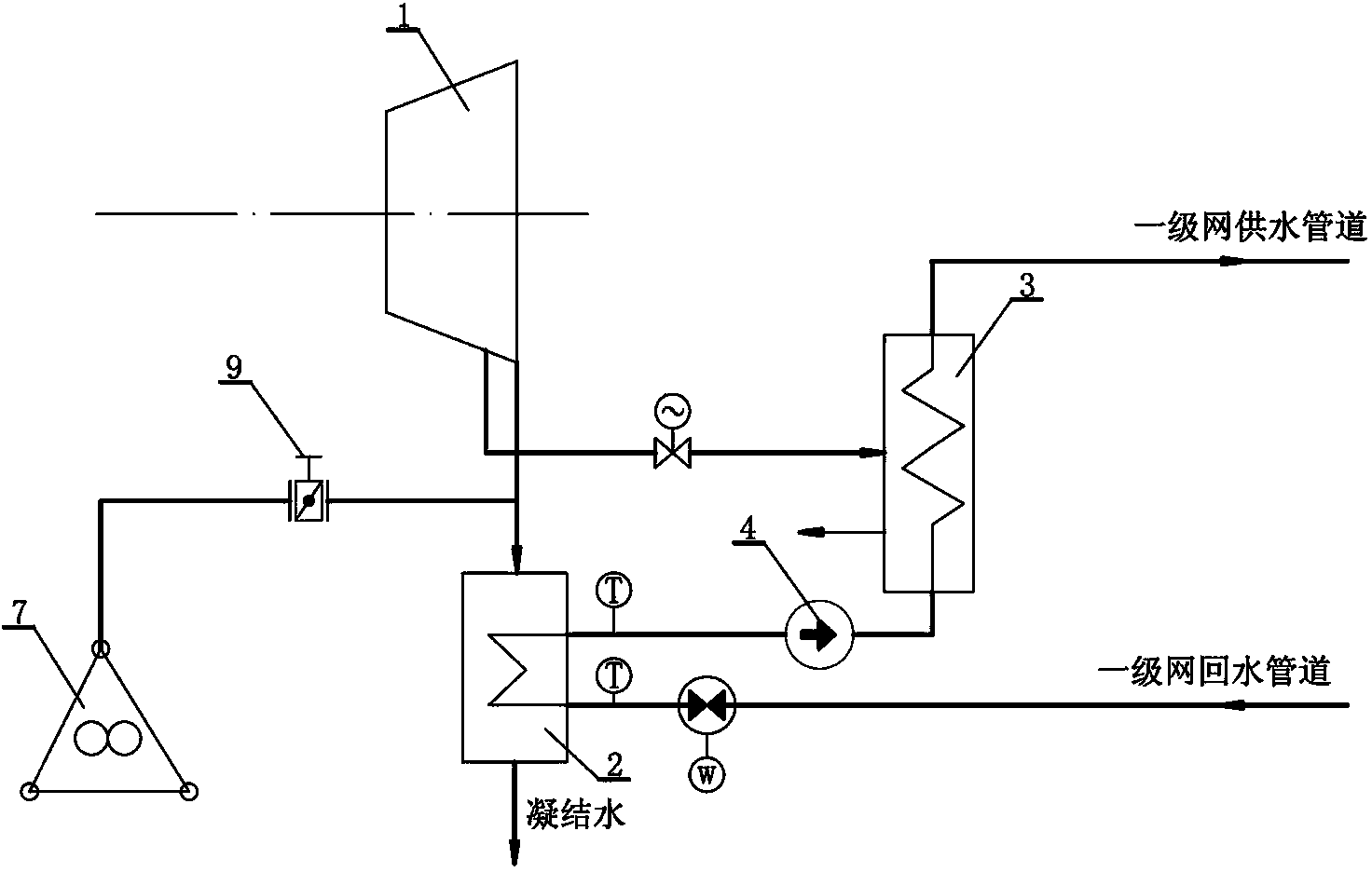

[0026] Embodiment 2 (air cooling system power plant)

[0027] Such as figure 2 As shown, the uncondensed exhaust steam of the condenser 2 is cooled by the air cooling island 7 of the power plant connected to the exhaust steam regulating valve 9 . That is, a proper amount of exhaust steam from the exhaust port of the steam turbine 1 of the power plant enters the condenser 2, and conducts preliminary heat exchange through the hot water heat exchange channel for the return water pipe of the primary network, and the remaining exhaust steam passes through the air cooling island of the power plant connected by the exhaust steam regulating valve 9 7 Cool. All the other structures are the same as in Embodiment 1.

[0028] This structure is suitable for power plants with an air-cooling system lacking in water sources, and part of the exhaust steam that is not utilized by the hot water heat exchange channel is cooled by the air-cooling island 7 .

[0029] Utilize the energy-saving d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com