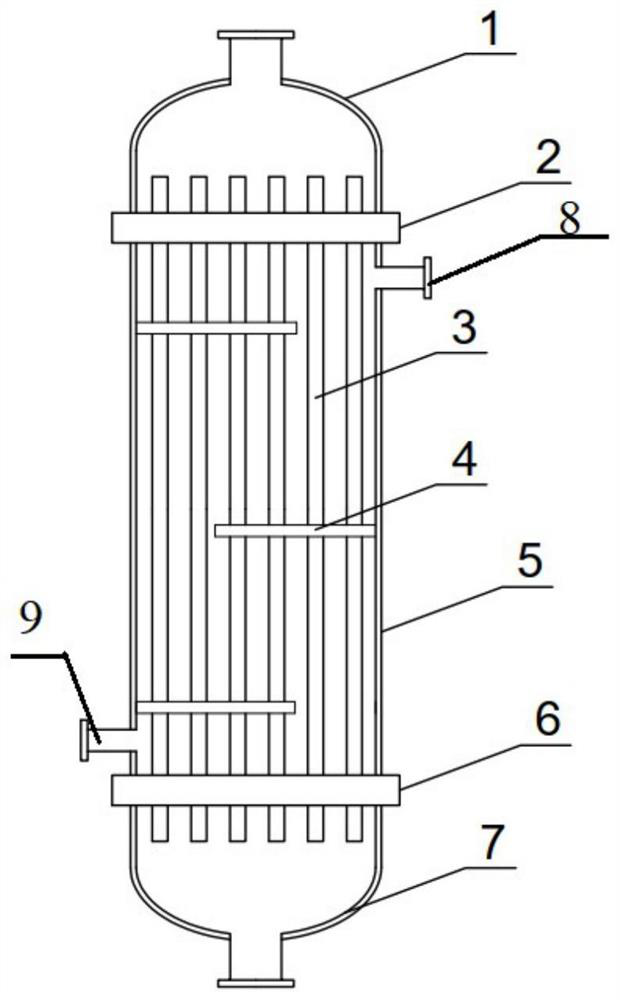

Catalytic membrane contactor and gas desulfurization and denitrification method

A technology of desulfurization and denitrification, membrane contactor, applied in chemical instruments and methods, separation methods, separation of dispersed particles, etc., can solve the problems of poor removal rate and low absorption efficiency, achieve wide application range and improve mass transfer efficiency And, the effect of increasing the degree of turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

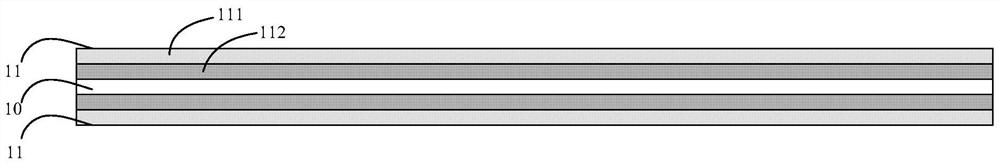

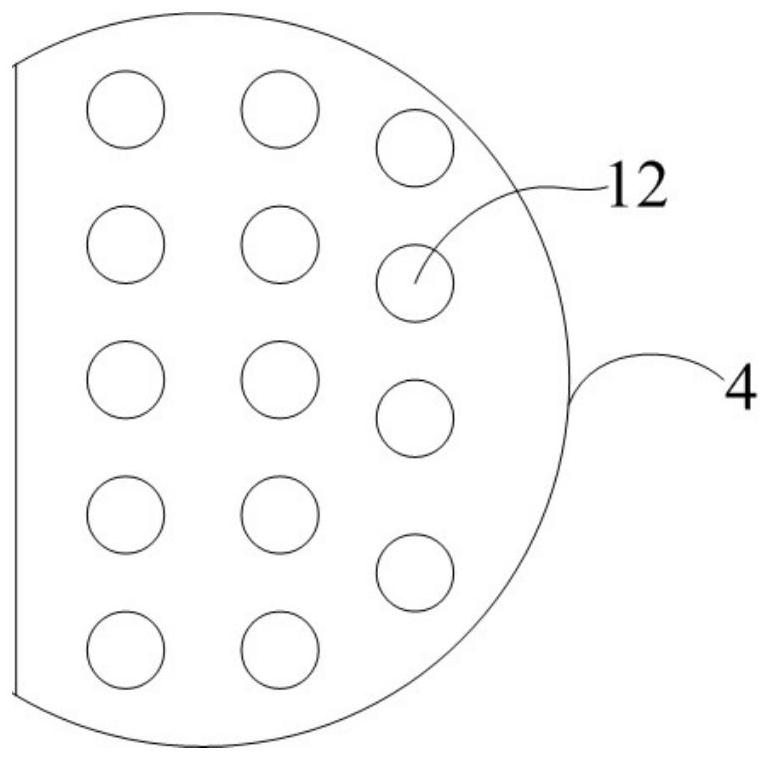

[0064] The catalytic membrane contactor is installed at the exhaust outlet of the ship, after the particulate filter. The absorbent is injected into the liquid inlet area from the liquid inlet head, and the absorbent flows out from the liquid outlet head through the ceramic membrane tube, and then enters the absorption liquid cooler and then circulates into the catalytic membrane contactor. After adding 500ppm ammonia to the tail gas, it enters the gas phase area of the catalytic membrane contactor through the gas inlet (the gas temperature is about 200°C and the liquid temperature is about 95°C). The temperature is about 60°C) and discharged. The NaOH solution with a concentration of 0.1mol / L is used as the absorption liquid, and the flow rate is 100m 3 / h. Exhaust gas flow is 50m 3 / h, where SO 2 The concentration is 100ppm, and the NO concentration is 100ppm. The volume of catalytic membrane contactor equipment is 4.5m 3 , the pore diameter of the membrane tube is 0...

Embodiment 2

[0066] The catalytic membrane contactor is installed at the exhaust outlet of the ship, after the particulate filter. The absorbent is injected into the liquid inlet area from the liquid inlet head, and the absorbent flows out from the liquid outlet head through the ceramic membrane tube, and then enters the absorption liquid cooler and then circulates into the catalytic membrane contactor. After adding 800ppm ammonia to the tail gas, it enters the gas phase area of the catalytic membrane contactor through the gas inlet (the gas temperature is about 150°C and the liquid temperature is about 90°C). The temperature is about 50°C) and discharged. The NaOH solution with a concentration of 1mol / L is used as the absorption liquid, and the flow rate is 300m 3 / h. Exhaust gas flow is 300m 3 / h, where SO 2 The concentration is 1000ppm, and the NO concentration is 1000ppm. The volume of catalytic membrane contactor equipment is 78.6m 3 , the pore diameter of the membrane tube is...

Embodiment 3

[0068] The catalytic membrane contactor is installed at the exhaust outlet of the ship, after the particulate filter. The absorbent is injected into the liquid inlet area from the liquid inlet head, and the absorbent flows out from the liquid outlet head through the ceramic membrane tube, and then enters the absorption liquid cooler and then circulates into the catalytic membrane contactor. After adding 800ppm ammonia gas to the tail gas, it enters the gas phase area of the catalytic membrane contactor through the gas inlet (gas temperature is about 180°C and liquid temperature is about 90°C), and is reacted by the catalyst through the gas outlet (gas temperature is about 120°C and liquid temperature is about 120°C). The temperature is about 70°C) and discharged. Ca(OH) with a concentration of 0.5mol / L 2 The solution is used as the absorption liquid, the flow rate is 100m 3 / h. Exhaust gas flow is 200m 3 / h, where SO 2 The concentration is 100ppm, and the NO concentrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com